Subcategories

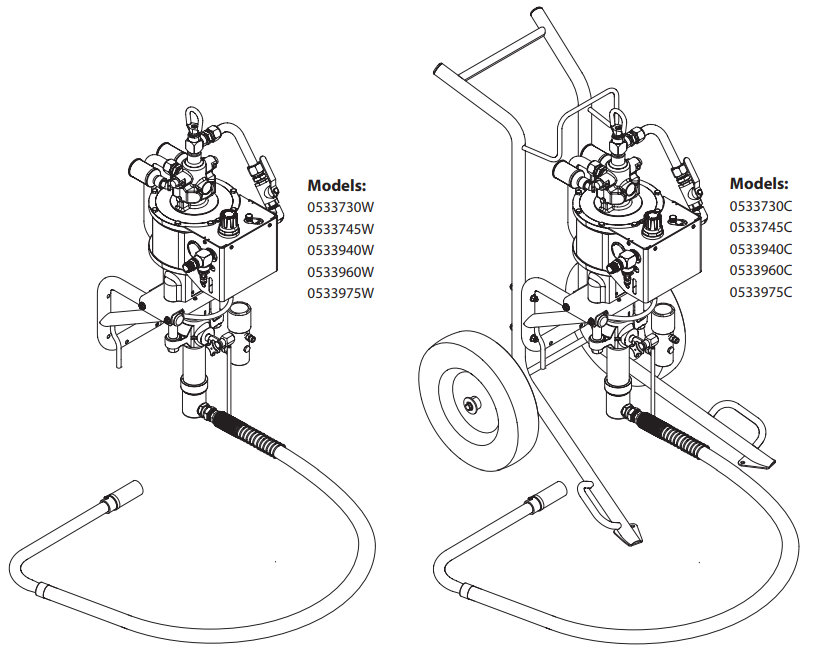

PowrCoat 730 Main Assembly Parts

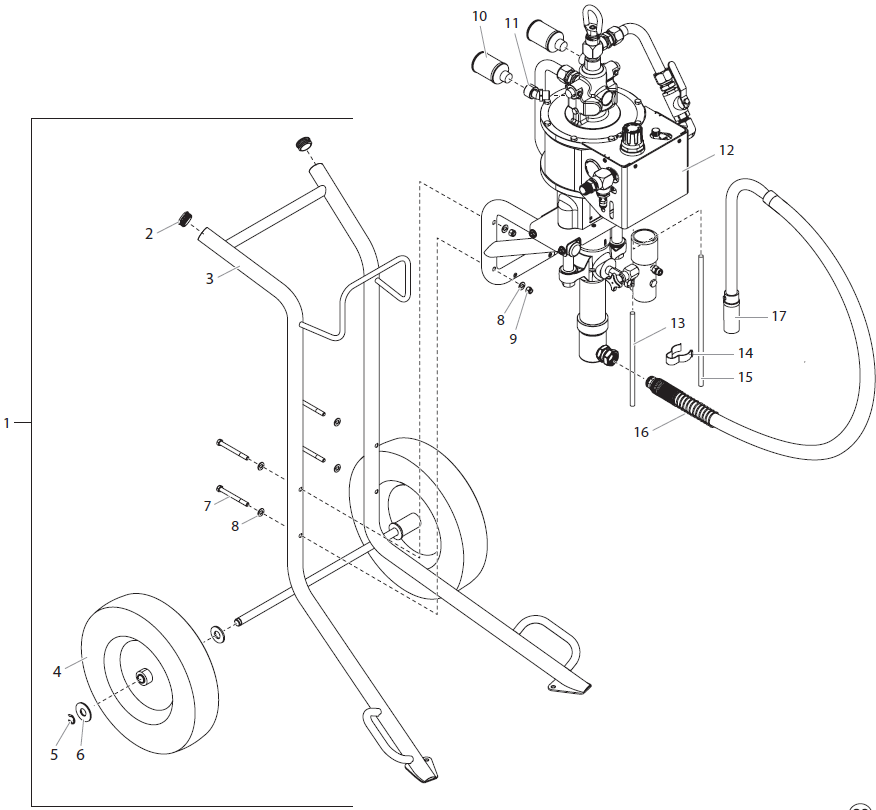

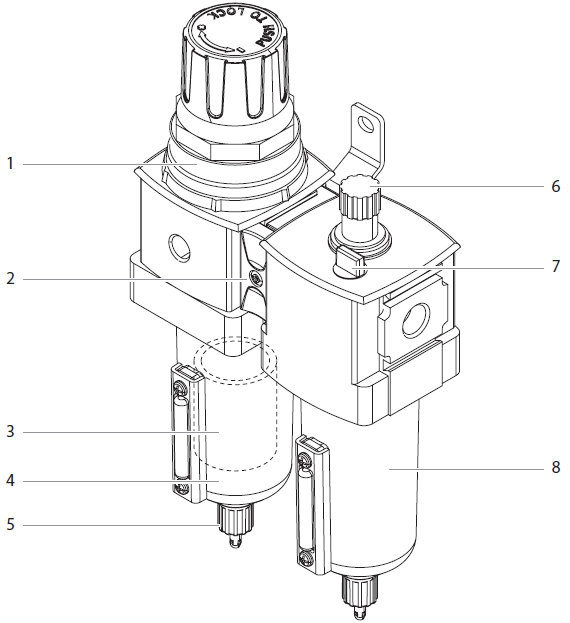

PowrCoat 730 Wall Mount Assembly Parts

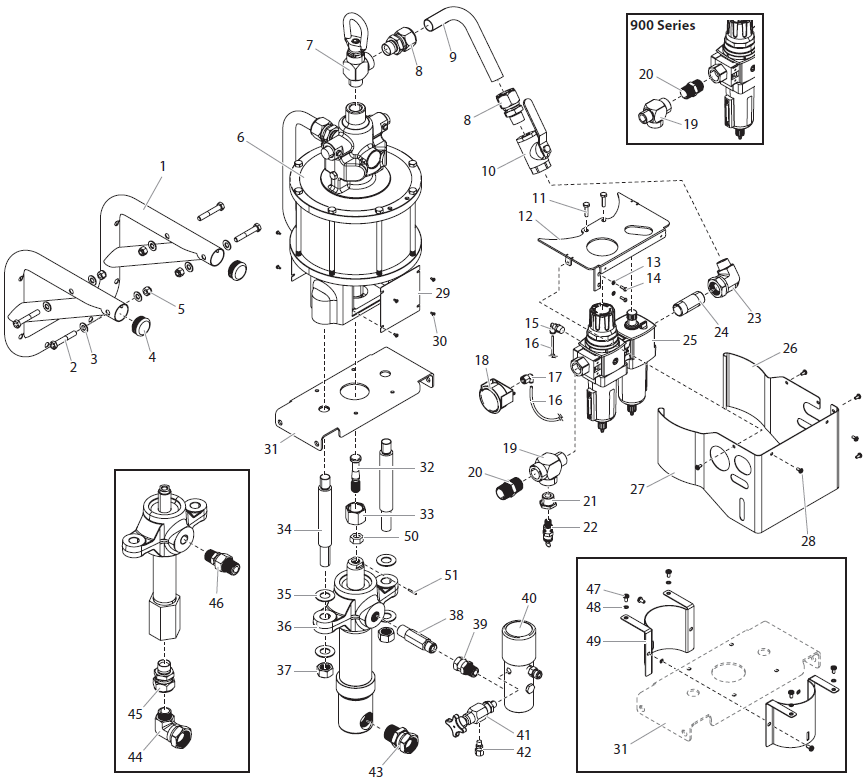

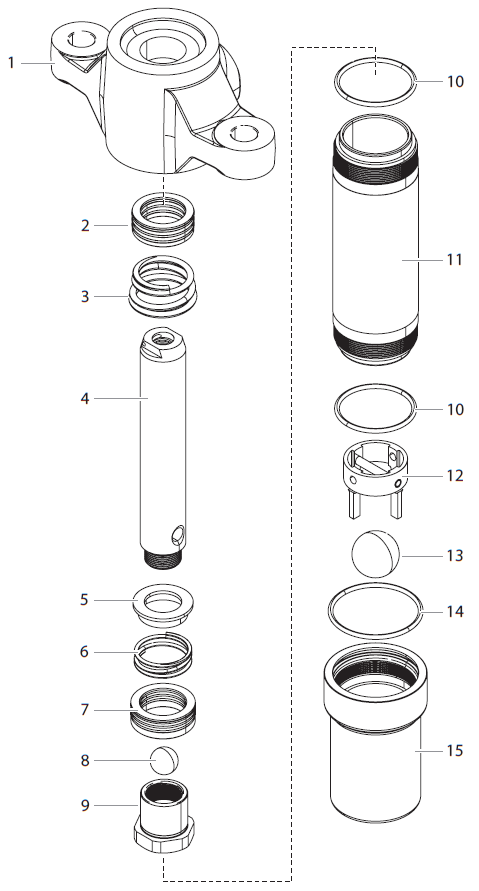

PowrCoat 730 Air Motor Assembly Parts

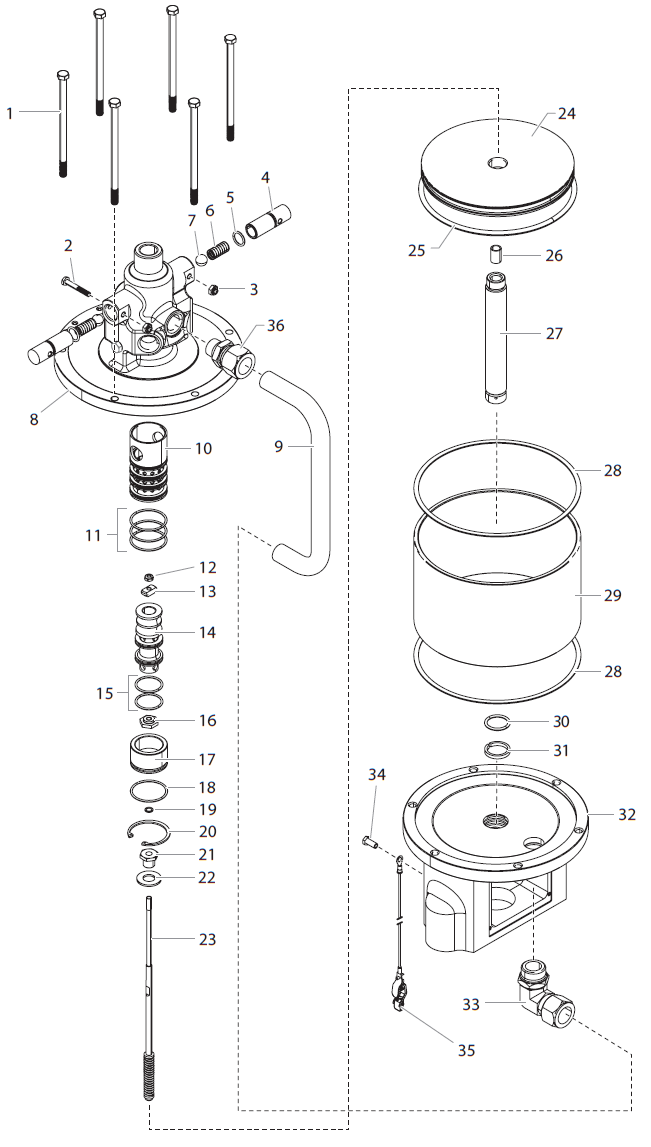

PowrCoat 730 Fluid Pump Assembly(185-551) Parts

PowrCoat 730 Automatic Lubricator Assembly Parts

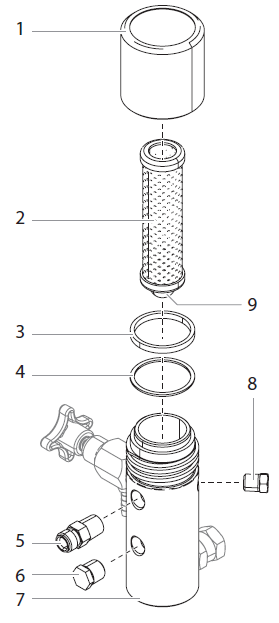

PowrCoat 730 High Pressure Filter Parts

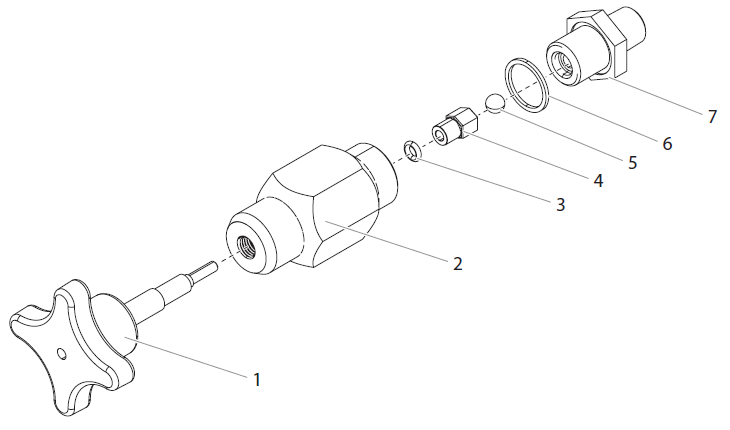

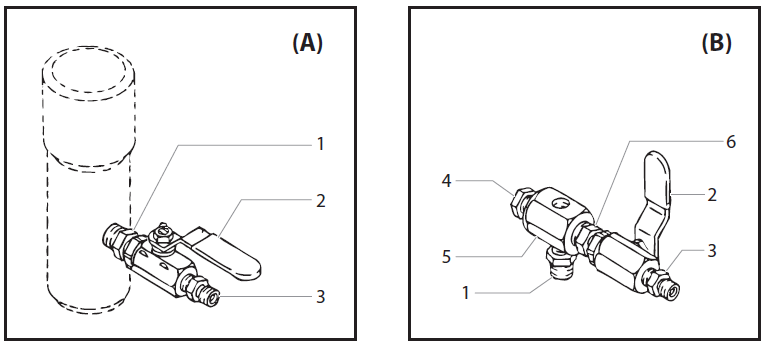

PowrCoat 730 Bleed Valve Assembly Parts

PowrCoat 730 Gun Manifold Assemblies Parts

PowrCoat 730 Accessories Parts

NEW PRODUCTS FOR FEBRUARY - POWRCOAT 730

The PowrCoat 730 is a high-output industrial airless coating system designed for continuous, heavy-duty spraying in production and plant environments. Engineered primarily as a wall-mount system, the PowrCoat 730 delivers reliable pressure, smooth material flow, and consistent spray performance for demanding protective coating applications.

Built with a powerful air motor, precision Fluid Pump Assembly, and advanced filtration and lubrication systems, the PowrCoat 730 is ideal for fixed-location operations that require durability, efficiency, and minimal downtime. A complete range of PowrCoat 730 replacement parts is available to support maintenance, repairs, and system upgrades.

The PowrCoat 730 is a wall-mount industrial airless coating system designed for fixed-location, continuous-use applications.

It uses the PowrCoat 730 Fluid Pump Assembly, specifically designed for high-viscosity and protective coating materials.

The automatic lubricator reduces friction and wear on internal components, helping extend the life of the air motor and pump assemblies.

High-pressure filters should be inspected regularly and cleaned or replaced when contamination or pressure drop is observed.

Yes, using genuine PowrCoat 730 parts ensures proper fitment, reliable performance, and long-term system durability.