Titan’s Air-Powered Airless Sprayer is incredibly dependable and provides mobility and a rapid spray with little maintenance. AlltitanParts has all the Titan Air Powered Airless Sprayer parts available to shop online.

These are the qualities of the Titan Air Powered Airless Sprayer that make it a durable mainstay on the job site.

- Pistons and cylinders with a hard chrome polish for a longer life

- Lubrication modification to increase adaptability

- High-capacity outlet filter to prevent blockage of the tips

- With a smoother stroke and unsurpassed chemical and solvent resistance, the titan PowrCoat piston reduces friction and wear.

- The AirCare technology stops motor icing.

Severe Service

- For a longer lifespan, cylinders and pistons with hard chrome polish are used.

- Hardened steel check balls with tungsten carbide valve seats for improved durability

AirCare System

- Filter, regulator, and lubricator (FRL) are standard for every titan PowrCoat.

- Automatic moisture trap draining.

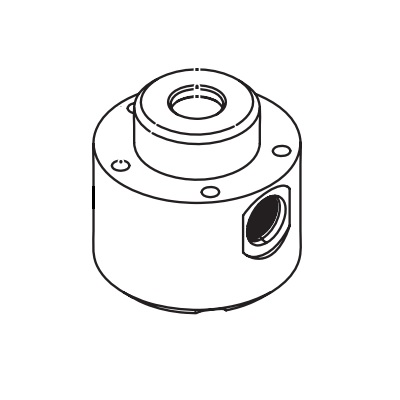

Severe Service Pump

- Long and slow piston strokes increase strength and durability.

- Packings that automatically adapt to provide optimal performance.

Buy Titan Air-Powered Airless Sprayer Parts from AllTitanParts!

Do you have any damaged Air-Powered Airless Sprayer parts while in the middle of the project? Worry not! Choose from our wide range of Air-Powered Sprayer parts to help fix your Titan Sprayer. AllTitanParts allow you to complete any job safely and more time-efficiently.

Air‑powered and airless sprayers are versatile workhorses for applying paint and coatings across a wide range of surfaces. Whether you’re tackling large commercial jobs, residential painting projects, or textured finishes, having the right replacement parts ensures your sprayer always performs at its best. Air‑Powered & Airless Sprayer Parts help maintain consistent spray quality, reduce downtime, and extend the life of your equipment.

These parts include everything from fluid section components and spray gun assemblies to filters, hoses, valves, and seals, each designed to keep your sprayer operating smoothly, reliably, and with greater precision. Quality replacement parts help prevent clogs, uneven spray patterns, pressure loss, and unnecessary wear, making maintenance easy and efficient. By using the right parts for the right job, you can improve finish quality, cut operating costs, and keep productivity high.

Key Features

- From internal pump components to external spray guns and accessories, air‑powered and airless sprayer parts cover all essential systems that affect performance, flow, and finish quality.

- Built to withstand heavy use, abrasive coatings, and frequent assembly/disassembly, these parts are designed for long service life in demanding environments.

- High‑quality seals, valves, and fluid system components ensure consistent pressure and even spray patterns, improving overall coating quality.

- Clear categorization and engineered fit make it simple to find and install the correct replacement part, reducing downtime and keeping your sprayer operational.

- Using the appropriate air‑powered or airless sprayer parts ensures smooth material flow, reduces waste, and delivers professional‑caliber results.

Applications

Air‑Powered & Airless Sprayer Parts are essential for:

- Interior and exterior painting projects

- Commercial coating and maintenance work

- High‑volume residential repainting

- Texture and specialty coating applications

- Automotive and industrial finishing

- Wood coating, cabinetry, and metalwork

FAQs

1. What are the most common parts that wear out on an airless sprayer?

Wear typically occurs in fluid seals, packings, spray tips, and filters. Regular inspection and replacement of these parts help maintain performance and prevent clogs or pressure loss.

2. How do I know when to replace the spray gun assembly?

If you notice a change in spray pattern, difficulty in controlling output, or leaking around the gun assembly, it’s a sign that the spray gun and its seals or internal components may need servicing or replacement.

3. What causes low pressure or inconsistent spraying?

Low pressure or uneven spray often comes from worn pump packings, clogged filters, or leaks in the fluid hose or valves. Checking and replacing these parts can restore proper pressure and improve performance.

4. How can I prevent clogs and buildup in my air‑powered or airless sprayer?

After each use of an air‑powered or airless sprayer, flush the system thoroughly, clean filters, and inspect hoses for debris. Regular cleaning prevents dried material from building up in fluid paths, reducing clogs and wear on internal components.

5. Why is it important to use the correct replacement parts for the SPEEFLO Admiral Air Powered Airless Sprayer?

Using replacement parts specifically designed for the SPEEFLO Admiral Air Powered Airless Sprayer ensures proper fit, reliable operation, and consistent spray performance. Genuine, model-specific parts help to prevent leaks or misalignment and reduce the risk of premature wear. Using incorrect or incompatible parts can lead to performance issues, unexpected breakdowns, increased downtime, and higher maintenance costs over time.