Subcategories

NEW PRODUCTS FOR FEBRUARY - MULTIFINISH 440 SPRAY SYSTEM

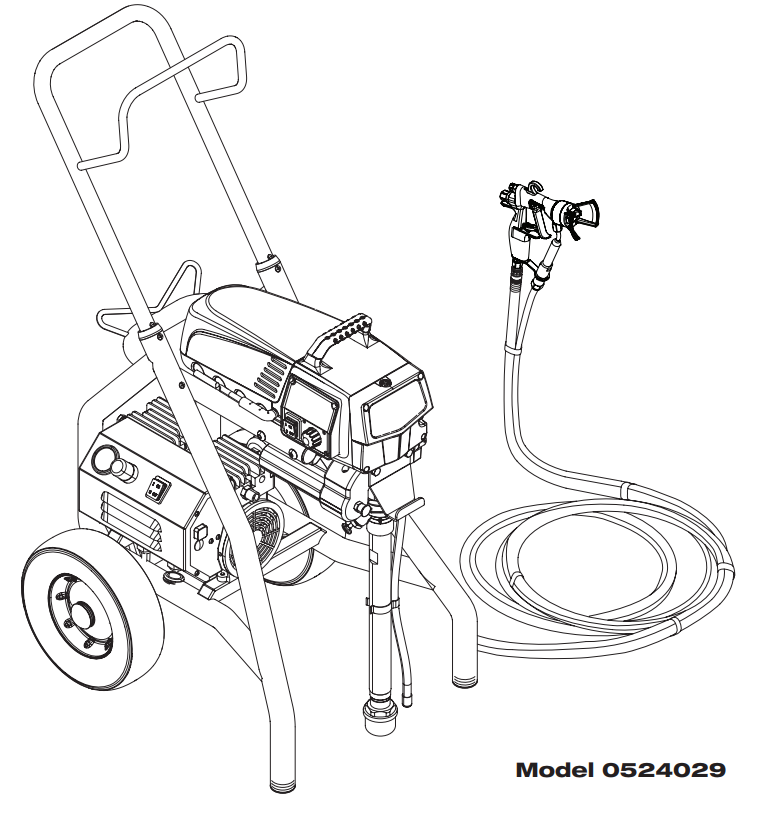

For contractors who want accuracy, effectiveness, and longevity in their spraying treatments, Multifinish's 440 Spray System is a high-performance option. Professionals in both residential and commercial projects use this adaptable system because it is perfect for applying a variety of coatings with a smooth and equal finish.

The Multifinish 440 Main Assembly and the Multifinish 440 Drive Assembly are among the many replacement parts available on alltitanparts.com for anyone wishing to maintain or repair your sprayer. The Drive Assembly supplies the power and motion required to maintain constant spraying pressure, while the Main Assembly serves as the sprayer's central component, guaranteeing peak performance and seamless operation.

Your Multifinish 440 Spray System's lifespan can be increased with routine maintenance and prompt part replacement, avoiding downtime and guaranteeing excellent results. Genuine OEM parts are available at alltitanparts.com for smooth compatibility and enduring performance. Get the best Multifinish 440 replacement parts and professional assistance right now to maintain the optimal performance of your machinery.

The Multifinish 440 Spray System is a high-performance airless spraying solution designed for professional and industrial finishing applications. Engineered for precision, durability, and consistent coating quality, this system delivers smooth spray patterns and reliable performance across a wide variety of materials, from primers and paints to stains and specialty coatings.

Whether you are working on wood, metal, or large surface areas, the Multifinish 440 ensures uniform coverage, reduced overspray, and professional-grade finish results. Its robust construction and user-friendly design make it suitable for both fixed installations and mobile jobsite use.

Pressure fluctuation is usually caused by worn packings, damaged inlet or outlet valves, or air entering the fluid section. Contaminated material or inadequate filtration can also restrict flow. Inspecting and replacing worn seals and valves restores stable pressure and consistent spray performance.

Unusual noise or power loss in the Multifinish 440 Drive Assembly typically indicates worn gears, loose drive components, or insufficient lubrication. Prolonged operation under high load can accelerate wear, making timely inspection and replacement of drive components essential to prevent failure.

Misalignment in the Multifinish 440 Main Assembly can result from loose fasteners, vibration during transport, or improper reassembly after maintenance. Misalignment can increase wear on the drive and fluid section components, so securing all mounting points and following proper assembly procedures is critical.

Although the Multifinish 440 Cart Assembly does not directly affect spraying pressure, damaged wheels, bent frames, or loose mounts can cause vibration and instability. This vibration can transfer to the pump and drive components, leading to premature wear if not corrected.

Basic airless sprayer knowledge is helpful, but the system is designed to be intuitive, making it accessible to professionals and experienced DIY users alike.