Subcategories

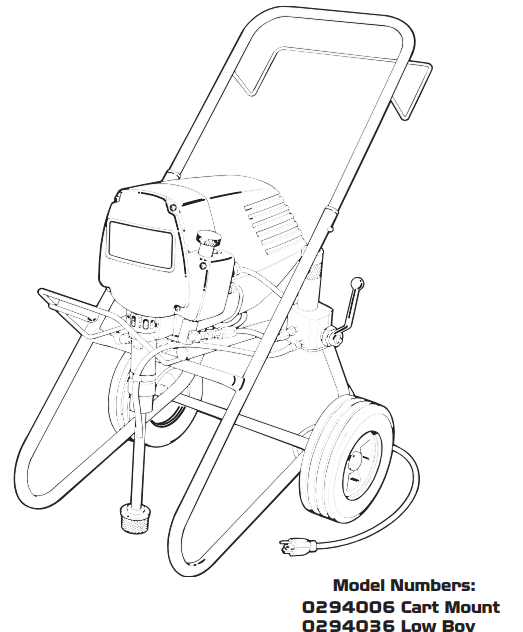

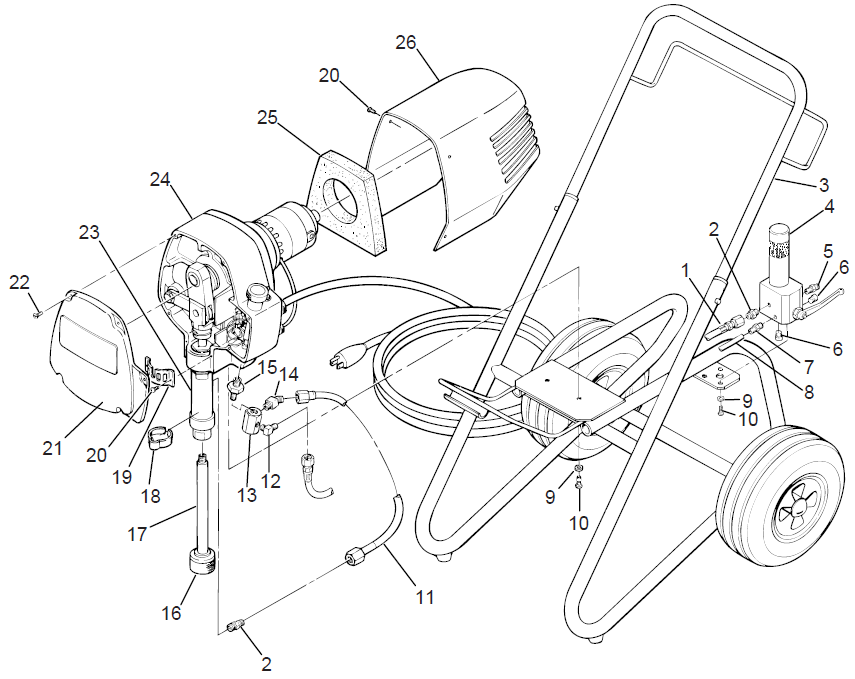

EP2300 Final Assembly Parts

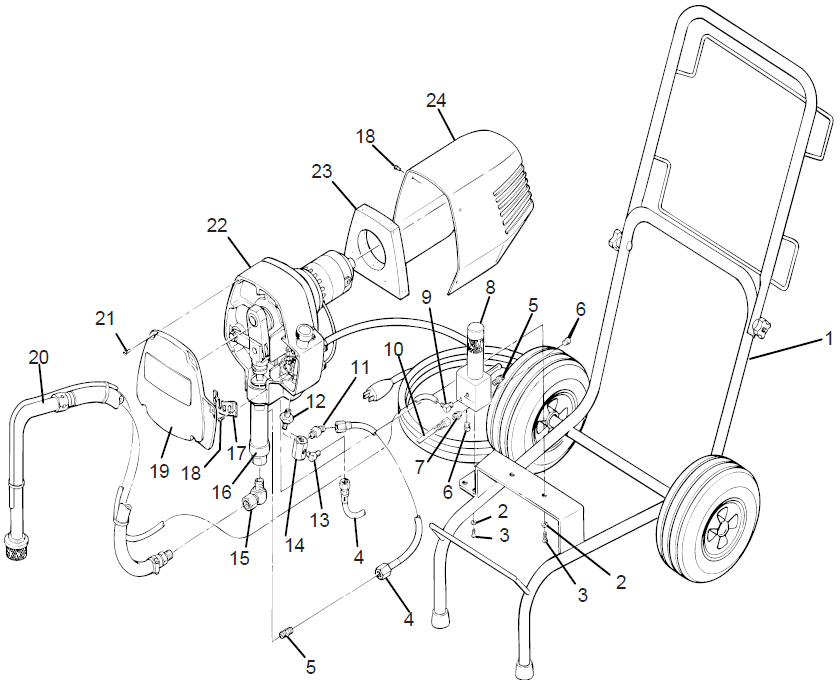

Titan/Spraytech EP2300 Low Boy Final Assembly Parts

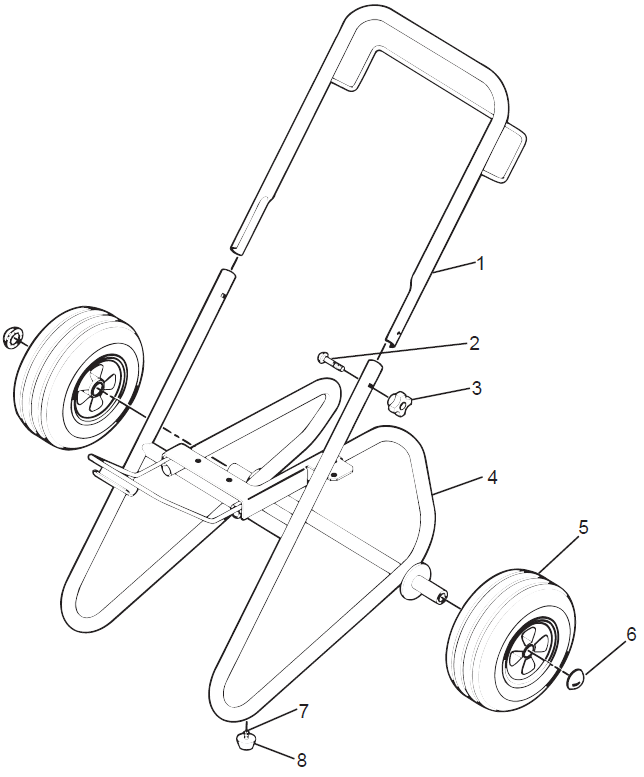

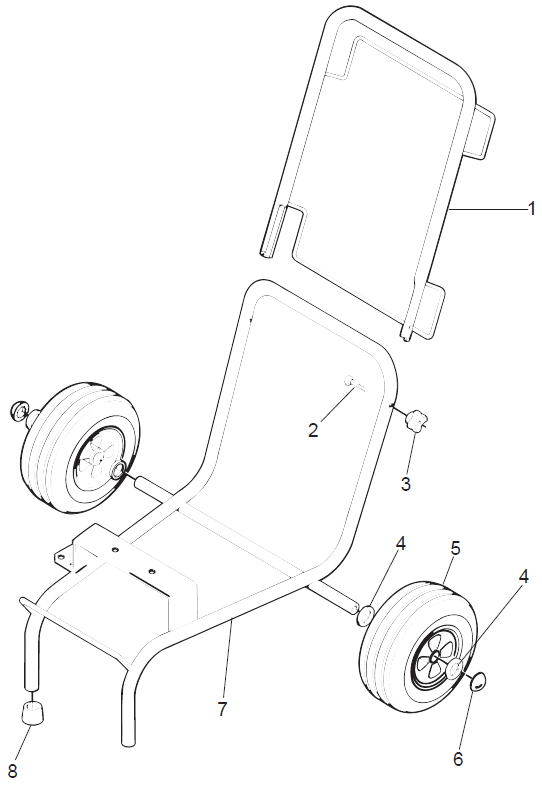

EP2300 Cart Assembly Parts

EP2300 Lowboy Cart Assembly Parts

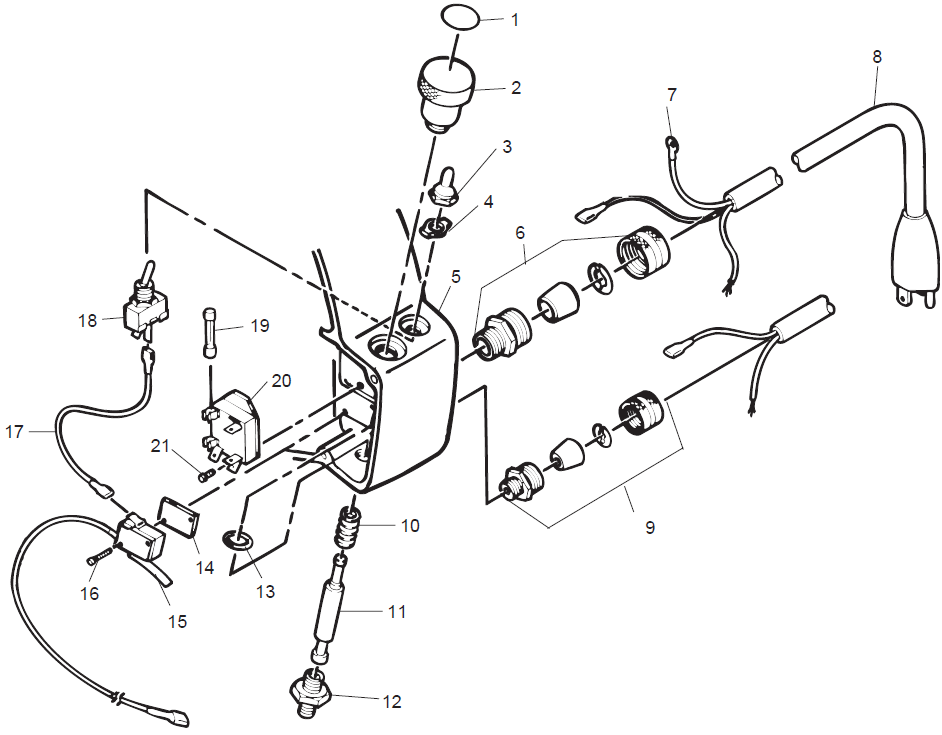

EP2300 Pressure Control Assembly Parts

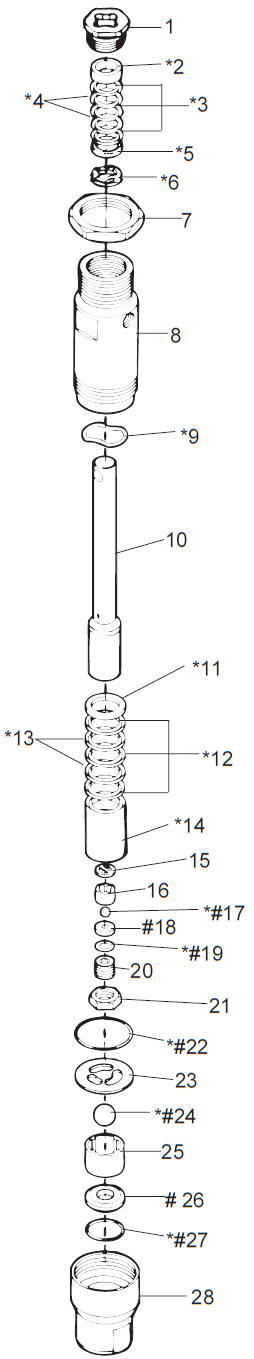

EP2300 Fluid Section Assembly Parts

EP2300 Transducer Assembly Parts

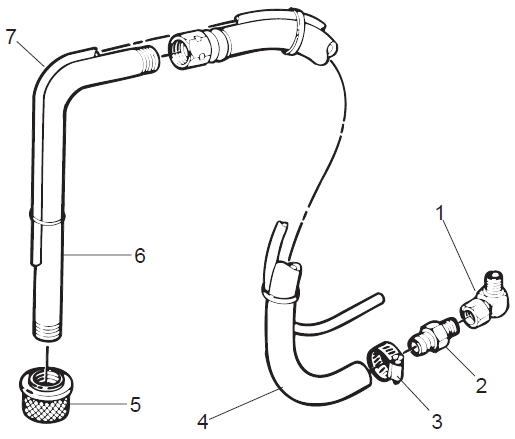

EP2300 Suction Set Assembly Parts

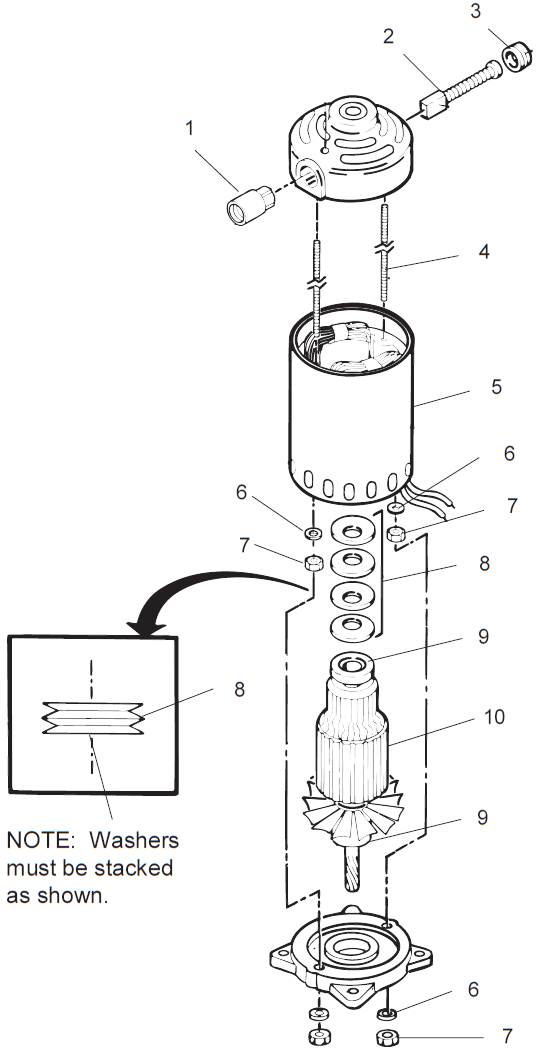

EP2300 Motor Assembly Parts

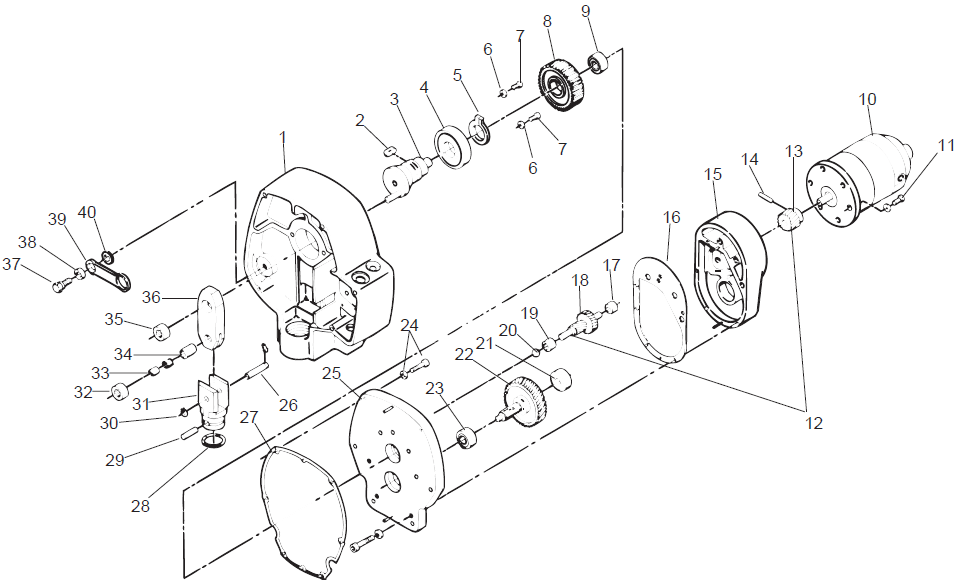

EP2300 Drive Assembly Parts

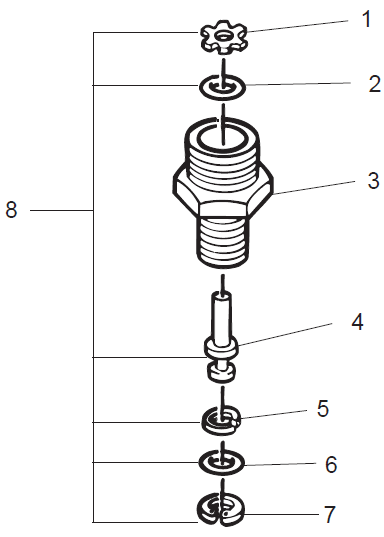

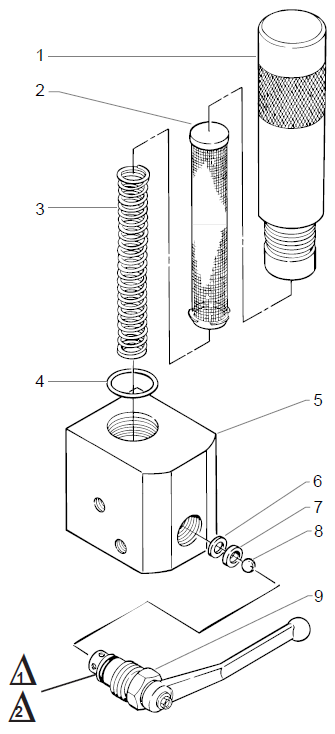

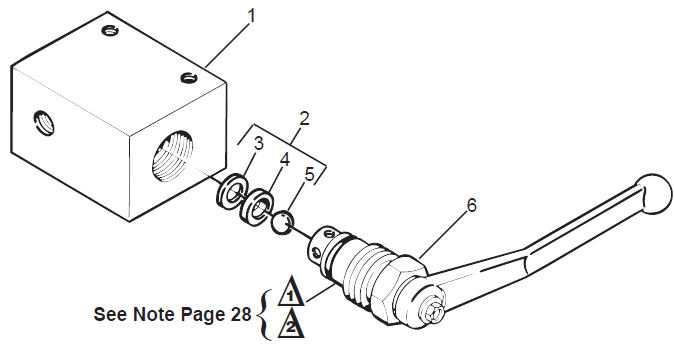

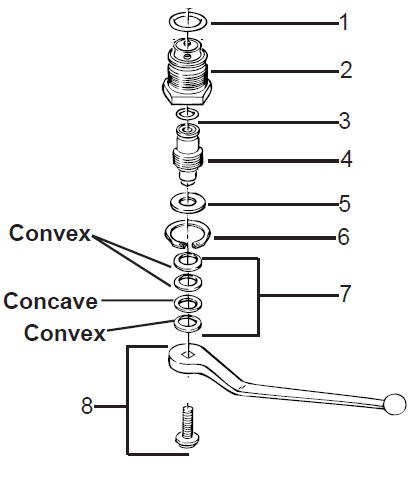

EP2300 Dump Valve Assembly Parts (0294220)

EP2300 Dump Valve Assembly Parts

EP2300 Dump Valve Cartridge Parts

EP2300 Accessories Parts

NEW PRODUCTS FOR FEBRUARY - EP2300 PISTON PUMP

Are there any missing or damaged Titan EP2300 Piston Pump component parts? Be at ease! Our team at AllTitanParts is here to help.

We've carefully separated the Titan EP2300 into separate assembly pieces, each with its own page, to make your search simpler. These pages have a clearly labeled diagram that should make the process simple.

Let's examine each assembly's specifics:

Including every replacement component required for your Titan EP2300 Piston Pump.

Contains the screw and return hose for smooth operation.

With the Hub Cap and Wheel Spacer Assembly, appreciate productivity.

Utilize the Hub Cap Guide and Wheel Spacer to ensure seamless functioning.

The Control Knob and Spring will give your sprayer more power.

Use the Wave Spring and packing nut to increase movement.

Use the Backup Ring and Piston to achieve steadiness.

Get all the replacement parts for your Titan Piston Pump you require in one location.

Comprises the motor brush and cap brush.

Comprises the connecting pin and ball bearing.

Dump Valve Assembly (0294220):

Consists of the valve seal and the filter support.

Includes the outlet valve ball and valve seal.

It has the Stem O-ring and Air Flow Valve within.

You may be confident that AllTitanParts carries every replacement component part you need for your piston pump. When choosing your replacement components, please refer to the labeled diagrams on our website to ensure correctness and the optimum fit. Spend less time looking around and place your order right now online!

1. What is the maximum operating pressure and flow rating of the EP2300 Piston Pump?

The EP2300 Piston Pump is designed to deliver up to 3000 PSI of operating pressure with a high-efficiency reciprocating piston system. Its flow output (approx. 1.0–1.2 GPM) supports medium- to heavy-duty spray applications including latex, acrylics, primers, and elastomeric coatings.

The EP2300 Fluid Section Assembly consists of:

These components ensure consistent suction, precise pressure delivery, and smooth pump cycling, even under high workloads.

The EP2300 Pressure Control Assembly uses:

Together, these systems actively adjust motor speed and pump stroke frequency, ensuring stable PSI output, eliminating surging, and protecting the pump from overload.

To maintain optimal performance:

Proper maintenance prevents motor overheating, noisy operation, and premature drive wear.

Common technical issues include:

Regular inspection of the fluid section, transducer, and dump valve assembly typically resolves these issues.