Subcategories

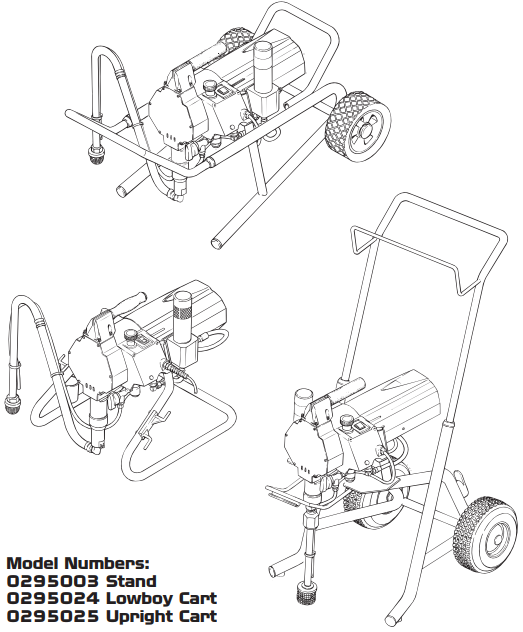

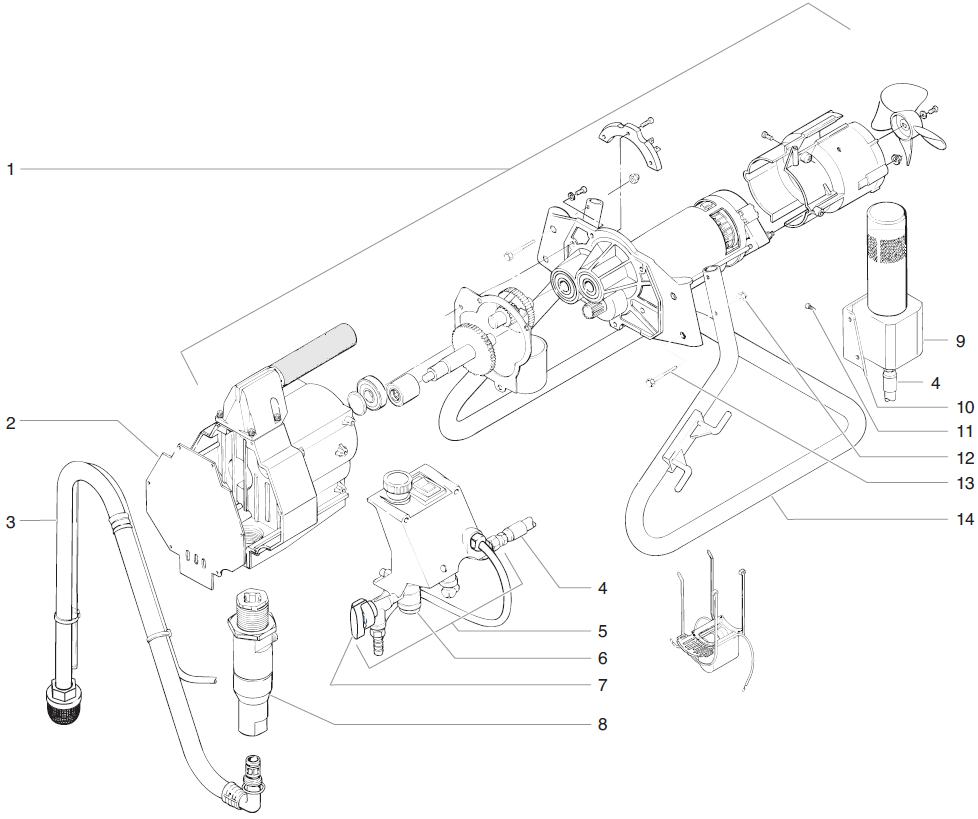

EP2205 Main Assembly

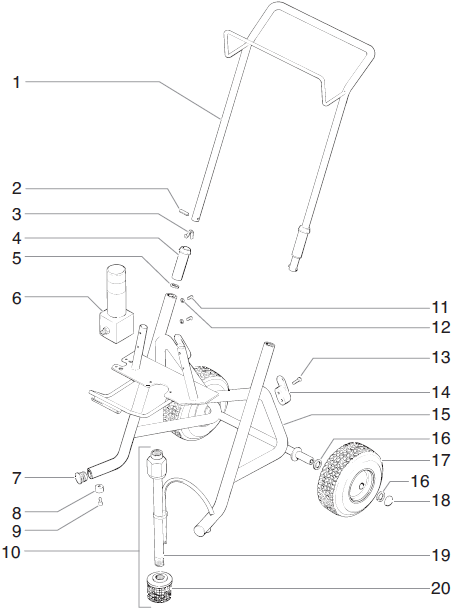

EP2205 Cart Assembly

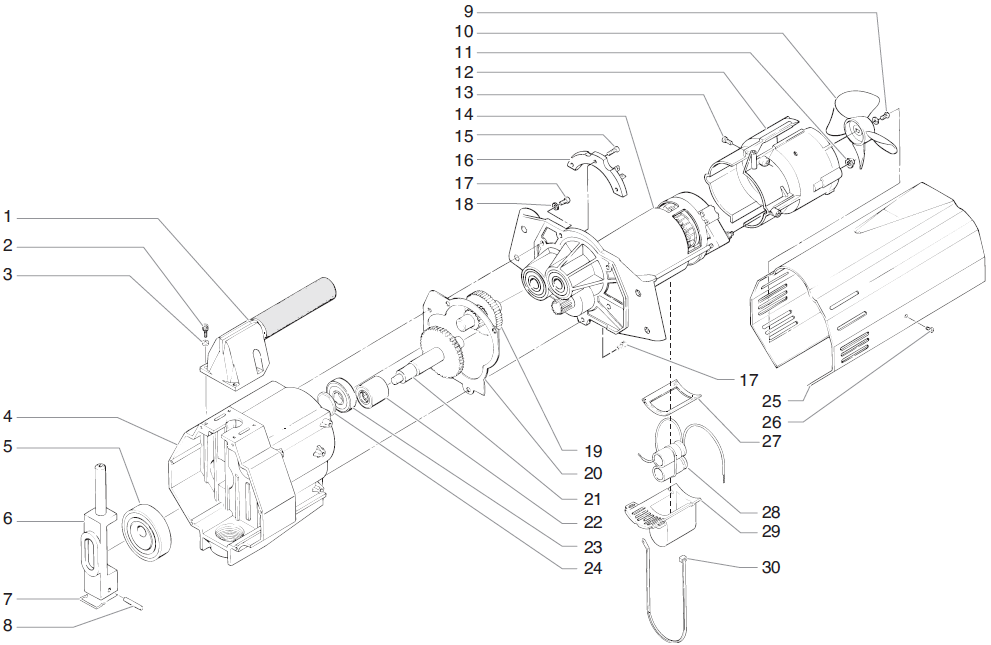

EP2205 Drive Assembly

EP2205 Transducer Assembly

EP2205 Suction Set Assembly

EP2205 Pressure Control Assembly

EP2205 Fluid Section Assembly

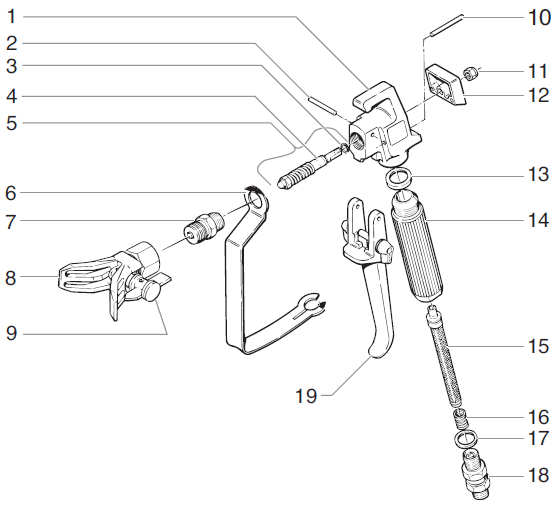

EP2205 Spray Gun (0502009)

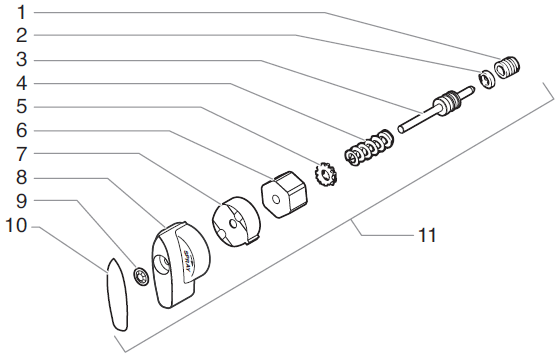

EP2205 PRIME/SPRAY Valve Assembly

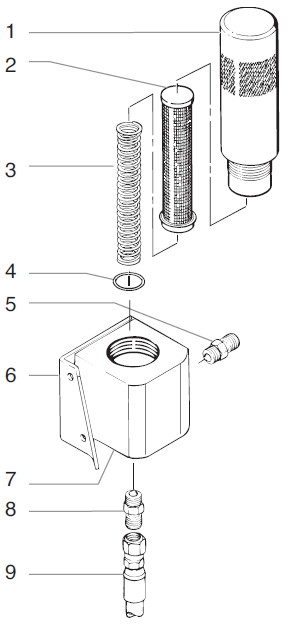

EP2205 Filter Assembly

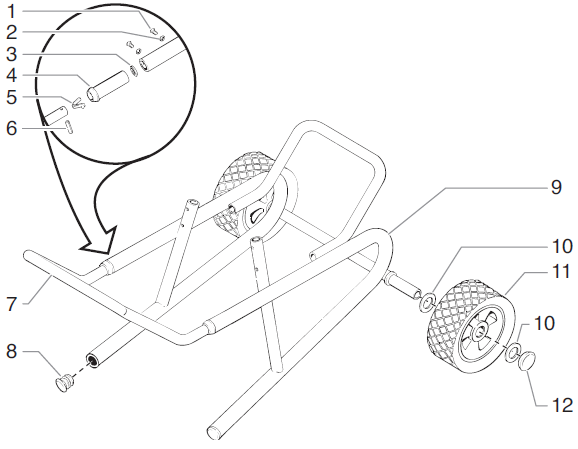

EP2205 Low Boy Cart Assembly

EP2205 Stand Assembly

Accessories

NEW PRODUCTS FOR FEBRUARY - EP2205 PISTON PUMP

Greetings from AllTitanParts, your one-stop shop for authentic Titan Piston pump components! Our goal is to make it simpler for our clients to locate and purchase the replacement assembly parts they require in order to maintain the optimal performance of their Titan EP2205 Piston Pump.

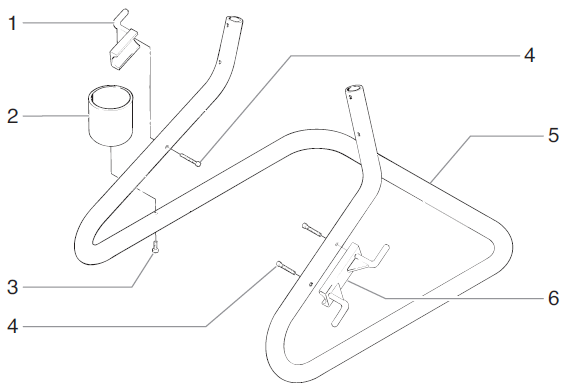

To make it easier for our clients to locate the parts they require, we have separated the piston pump into various assemblies. For easy access, each assembly has a labeled diagram on the corresponding page.

Let's examine our assemblies in more detail:

All of the interchangeable components for the piston pump, including the screw and transducer kit, are included in the Main Assembly. These are necessary components to maintain the proper operation of your sprayer.

The snap button and wheel spacer on the Cart Assembly are essential for fastening the cords and cables to the pump. Securing cords is essential for both safety and best results.

Another essential element for the sprayer's operation is the Drive Assembly, which also contains the Hex cap screw and fuse block screw.

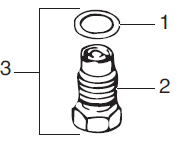

The O-ring and transducer kit, among other components, are part of the Transducer Assembly and are necessary for the pump's transducer to operate properly.

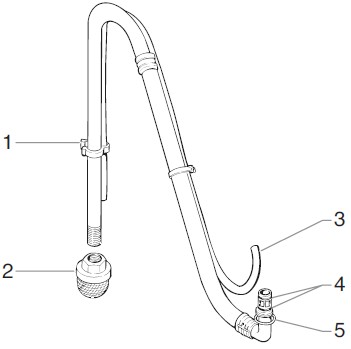

Another crucial assembly is the Suction Set Assembly, which has components like the O-ring and strainer that are essential to the pump functioning.

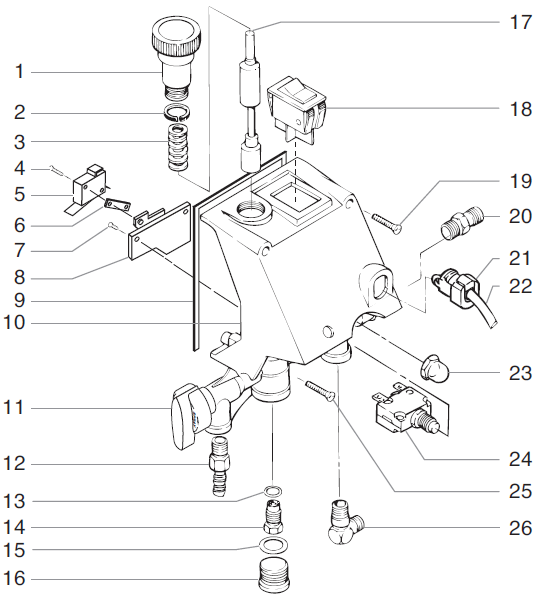

We have the Pressure Control Assembly, which includes components like the power switch and spring that are necessary for the pump to operate properly when utilizing this assembly.

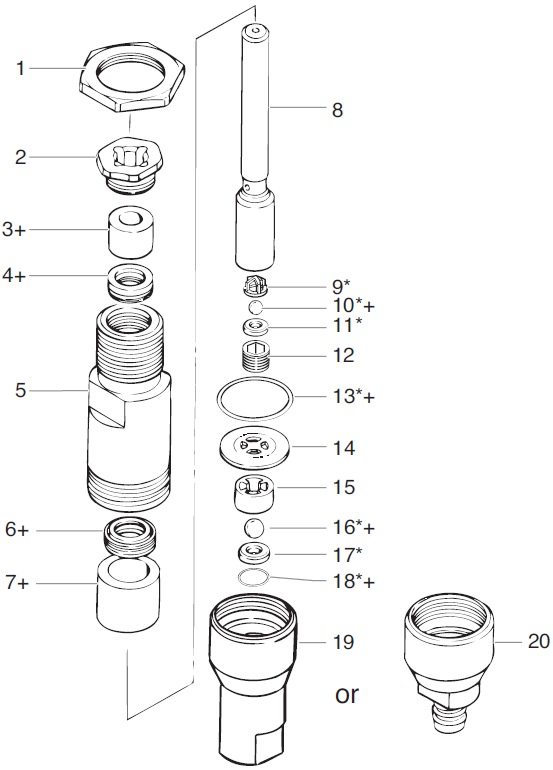

Fluid Section Assembly comprises the upper spacer and piston rod. These components are necessary to keep the paint flowing evenly and smoothly.

Fluid dynamics are realized with the Spray Gun spring and valve union assembly. See how well the application and spray are harmonized.

This package of Prime/Spray Valve Assembly parts include all the assembly components required for your piston pump. To ensure that the heart of the device is beating steadily, it has a retainer clip and a valve seat assembly.

This system includes the filter body assembly and filter support, which are necessary components for the Filter Assembly to charge your pump.

The snap button and wheel are included in the Low Boy Cart Assembly. The suction function of the atomizer requires these pieces.

The Stand Assembly intricacy is essential to its correct operation. Our drip cup screw guarantees flawless outcomes.

AllTitanParts is the reliable source for keeping your piston pump performing at its peak. Obtain substitute assembly components. Make your purchase instantly.

The EP2205 Piston Pump is engineered to deliver high-pressure output up to 3000 PSI, ensuring consistent atomization for professional-grade coatings. The pump’s fluid section and drive system are designed to maintain steady flow even with thicker materials such as latex, primers, elastomerics, and acrylics.

The EP2205 Fluid Section Assembly typically contains:

The Pressure Control Assembly monitors and adjusts system pressure using:

To maintain optimal pump performance:

Common symptoms and technical causes include: