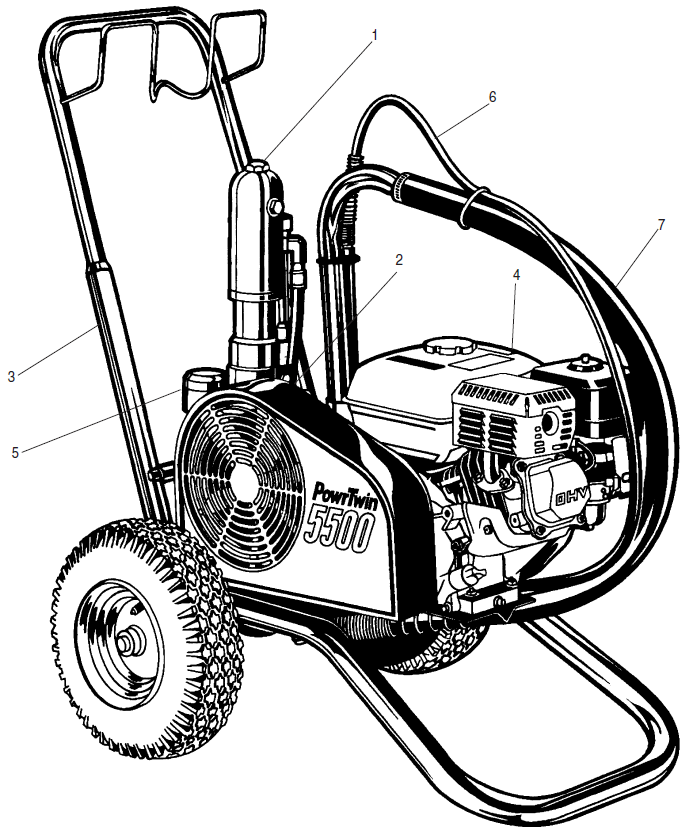

PowrTwin 5500 Airless Sprayer Parts

When you use a PowrTwin 5500 airless sprayer, having reliable access to replacement parts, from major assemblies to small maintenance components, ensures your sprayer remains safe, efficient, and ready for any coating job. This page organizes all genuine parts and sub‑assemblies for the 5500, making it simple to find what you need: whether you’re doing a full rebuild, replacing a worn pump, upgrading components, or servicing fluid delivery and filtration.

Key Parts & Sub‑Categories for PowrTwin 5500

The parts for the 5500 are organized into the following main sub‑categories:

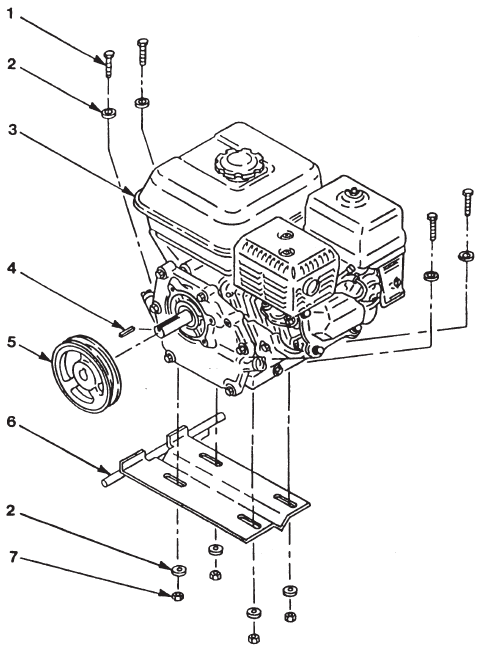

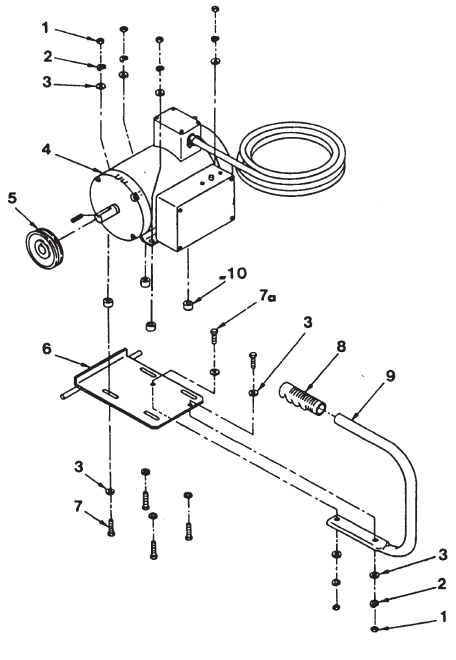

- Major Components — the core structural and mechanical assemblies of the sprayer (frame, mounts, primary assemblies) for major repairs or rebuilds.

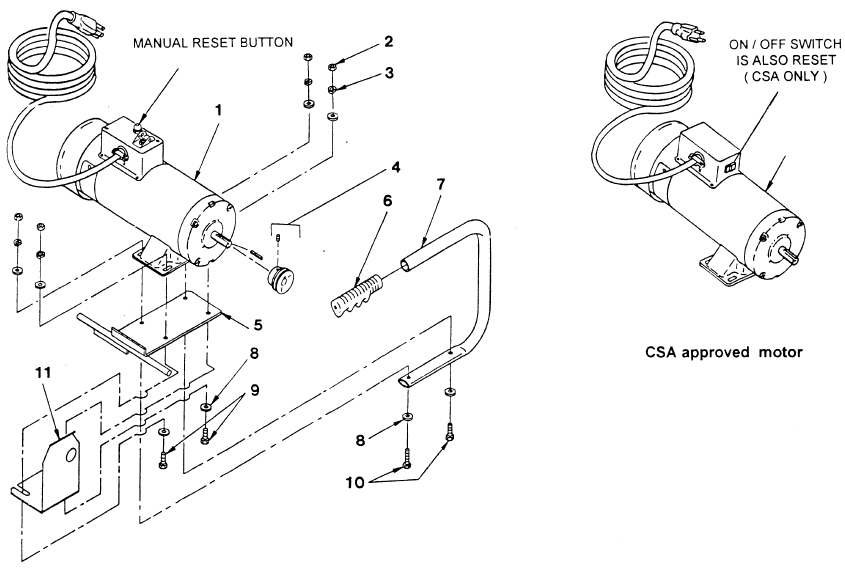

- Gas Convertokits, AC‑Electric Convertokits, DC‑Electric Convertokits — kits and parts to configure or convert the sprayer to different power sources (gas or electric).

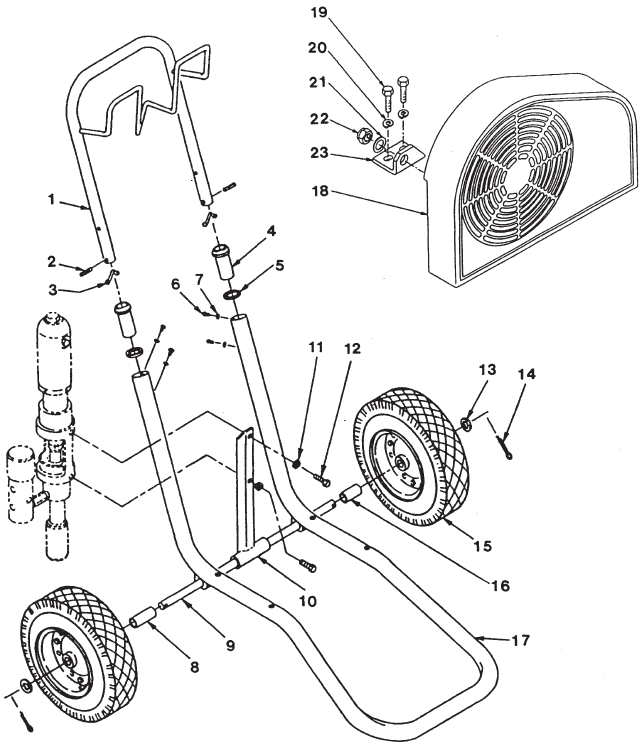

- Cart Assembly — wheels, frame, handles, and mobility/cart hardware for moving the sprayer on site.

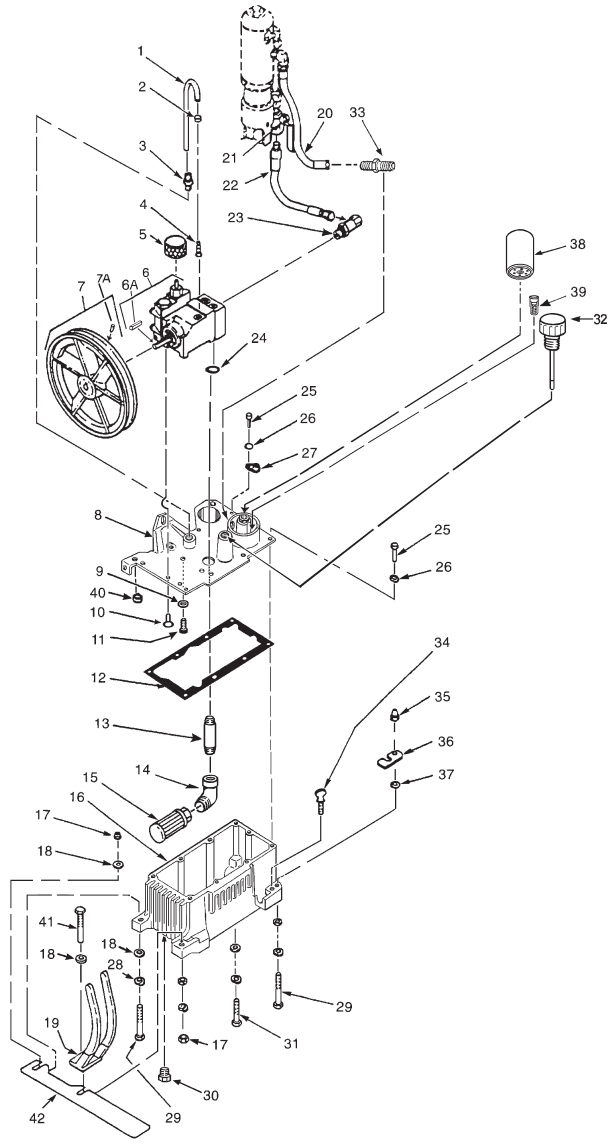

- Hydraulic System & Hydraulic Motor — the hydraulic drive and motor assemblies that power the fluid pump; critical for operation and fluid flow.

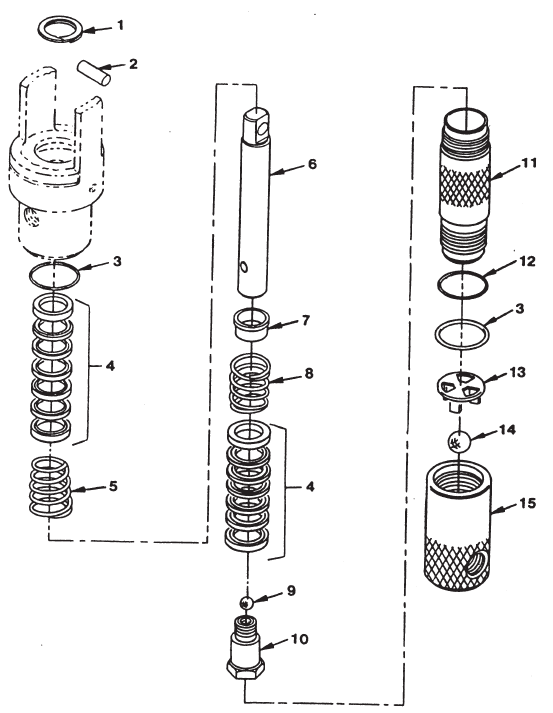

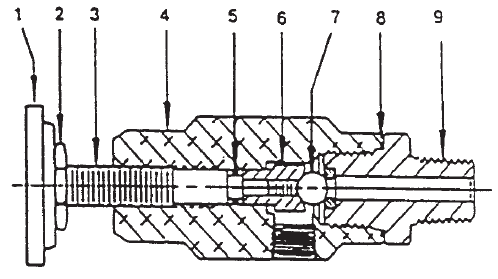

- Fluid Pump — piston/cylinder, rod, packings, valves, and related components are responsible for drawing and pressurizing fluid for spraying. The 5500 pump uses a hard chromium‑plated rod/cylinder for abrasion resistance and long packing life.

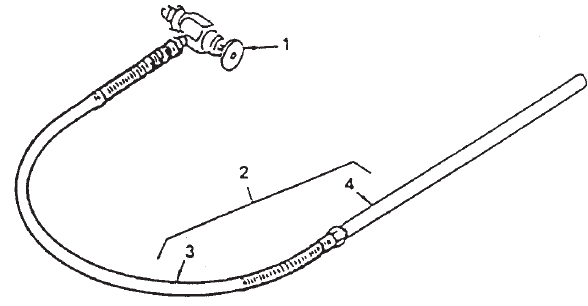

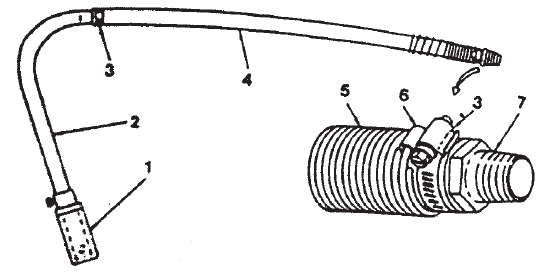

- Bleed Line Assembly With Valve / Bleed Valve Assembly — assemblies used for pressure‑relief, flushing, and safe maintenance/shutdown of the sprayer.

- Syphon Hose Assembly — suction hoses, foot‑valve or rock‑catcher assemblies for drawing paint or coatings from buckets or drums.

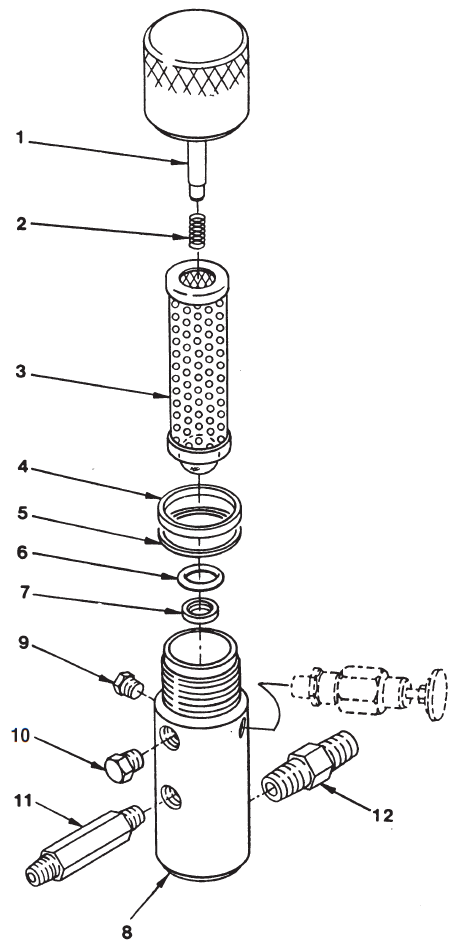

- Outlet Manifold Filter Assembly With Check Valve — manifold blocks, filters, check valves, and outlet fluid path components for fluid delivery to guns.

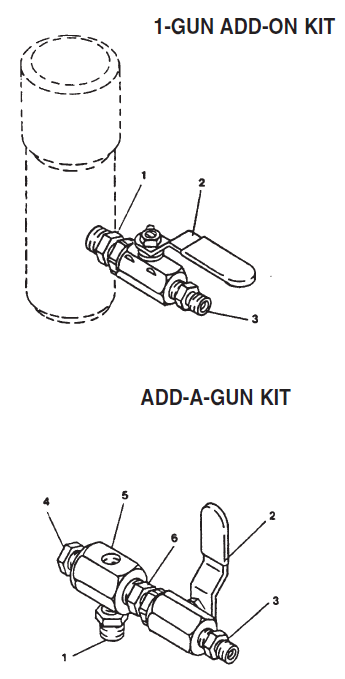

- Gun Manifold Assemblies — manifold and fittings to feed one or more spray guns from the 5500, for single‑gun or multi‑gun configurations.

- Accessories — additional parts, small components, maintenance kits, filters, gaskets, etc., for upkeep, repair, or enhancement of the sprayer.

Additionally, individual parts commonly replaced or maintained in repair cycles include fluid filters, valve seats, packings, seals, suction hose assemblies, bleed valves/lines, manifold filters, and many more.

Why Proper PowrTwin 5500 Parts Matter

- Durability under heavy-duty work — The 5500’s fluid pump uses a specially hardened chrome‑plated rod and cylinder, making it more abrasion-resistant than many comparable pumps. This extends packing life and reduces wear under heavy usage or abrasive coatings.

- Reliable pressure and fluid delivery — Genuine hydraulic, pump, valve and manifold components ensure that fluid is consistently drawn, pressurized, and delivered to the gun. Using the correct parts helps maintain spray pressure, avoid blockages, and ensure even spray patterns.

- Safety and proper maintenance — Bleed valves, bleed lines, and check valves are critical for safely depressurizing and maintaining the system. Genuine parts ensure correct fit and pressure handling when servicing.

- Versatility and power-source flexibility — With correct convertokits and modular components, the 5500 can be configured for gas or electric operation depending on the job site, enabling flexibility while ensuring proper compatibility.

- Ease of maintenance and part replacement — Organized sub‑categories help you quickly find the required component, whether you need a minor repair (like a gasket or filter) or a major overhaul (pump, motor, manifold). Minimizing downtime saves time and money on the job.

FAQs

1.What parts should I check first if my 5500 sprayer has low fluid output or poor spray performance?

Start with the Fluid Pump parts (packings, rod, seals), the Syphon Hose Assembly (suction issues), and the Outlet Manifold Filter Assembly (clogged or dirty filters or check‑valves). These are common causes for reduced fluid delivery or inconsistent spray.

2. Can I convert my 5500 from gas to electric (or between power types)?

Yes, the 5500 supports conversions via the appropriate Gas Convertokits or AC/DC Electric Convertokits. Use the convertokit to match your current configuration and power requirements.

3. How important is the bleed line/valve assembly for maintenance?

Very important, bleed line assemblies and valves are designed to safely relieve pressure before maintenance or cleaning. Using genuine bleed assemblies ensures proper pressure handling and safe maintenance procedures.

4. Is the fluid pump of the 5500 more durable than standard pumps?

Yes, the pump’s rod and cylinder use Titan’s exclusive hard chrome plating, which is more abrasion‑resistant than many standard materials. This design reduces friction and wear, extending the life of packings and improving long‑term reliability.

5. Where can I find minor maintenance parts like filters, gaskets, or sealing components?

Check under the Accessories sub‑category; replacement filters, gaskets, and small components are maintained there, enabling upkeep without needing large replacement assemblies.