Part #: 449-126

Part #: 431-042

Part #: 192-228

Part #: 448-243

Part #: 860-520

Part #: 859-001

Part #: 858-621

Part #: 858-624

Part #: 449-605

Part #: 472-500

Part #: 448-208

Part #: 759-456

Part #: 0509285

Part #: 448-213

Part #: 941-555

Part #: 448-235

Part #: 192-050

Part #: 325-031

Part #: 858-636

Part #: 858-002

Part #: 101-205A

Part #: 509292

Part #: 862-493

Part #: 227-027

Part #: 862-480

Part #: 335-010A

Part #: 449-621

Part #: 862-438

Part #: 862-402

Part #: 449-107

Part #: 449-135

Part #: 449-609A

Part #: 862-496

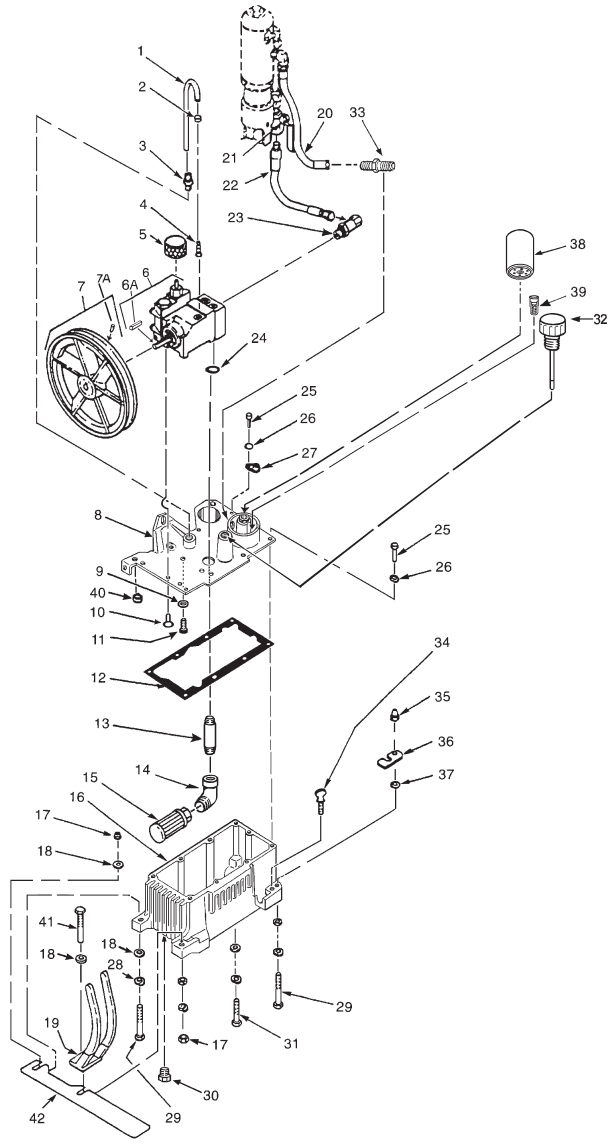

The hydraulic system is the core of your PowrTwin 5500’s power delivery, converting engine or motor power into the hydraulic pressure needed to drive the fluid pump, pressurize coating, and deliver consistent spray performance. This page gathers all genuine hydraulic‑system parts so you can maintain, repair, or rebuild your 5500 hydraulic drive with confidence and precision.

Here are the main genuine components listed under the Hydraulic System category:

These parts collectively make up the hydraulic fluid‑power system that drives the fluid pump, enabling the sprayer to pressurize paint or coating and deliver consistent spray performance under pressure.

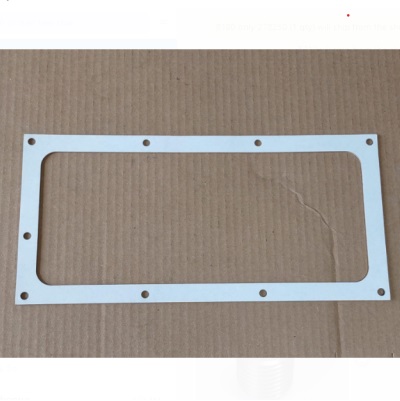

The hydraulic system includes the hydraulic pump (449‑502), hydraulic tank & tank cover & gasket, hoses and hose assemblies (return hose 448‑213, pressure hose 448‑235), inlet screen (448‑208) and hydraulic filter (449‑610), fittings and connectors (hoses clamp 449‑126, tube connector 431‑042, elbows/fittings), pressure control knob (448‑243), ball valve (941‑555), plus all necessary screws, washers, O‑rings, plugs and sealing hardware.

The hydraulic tank stores the hydraulic fluid required for the system. A properly sealed tank with a correct gasket and cover ensures fluid stays clean and uncontaminated, which helps maintain hydraulic pressure and extends pump and motor life.

Check hoses and fittings for leaks or damage, inspect the inlet screen or filter for clogging, verify the hydraulic pump integrity, and examine seals such as O‑rings or gaskets. Any leak or damaged part in the hydraulic fluid path can cause a pressure drop or failure.

Inspect filters (inlet screen and hydraulic filter) regularly, especially after heavy use or in dirty environments. Replace filters or seals whenever you notice debris, contamination, or any fluid delivery issues. Also, check hoses and clamps periodically for wear, leaks, or damage.