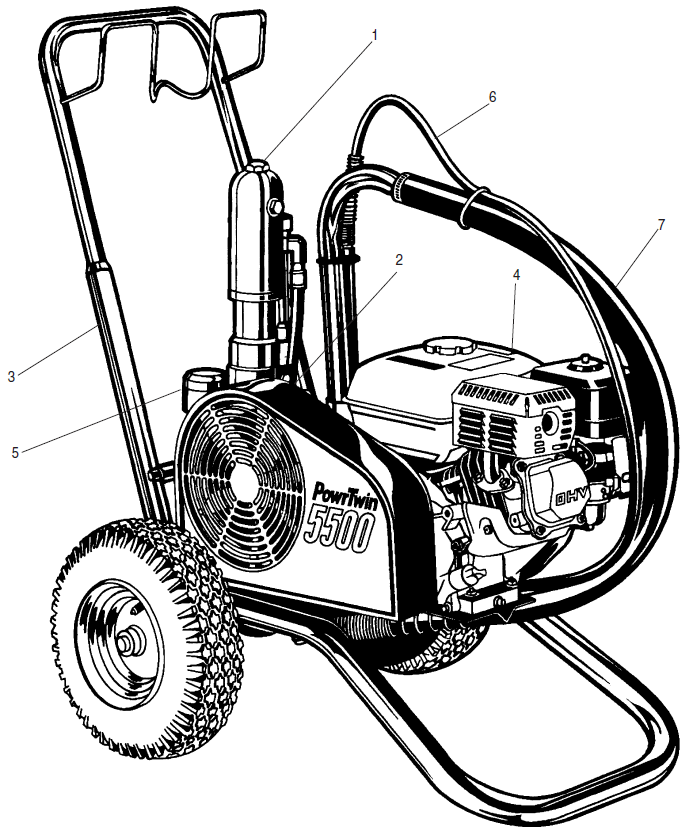

PowrTwin 5500 — Major Components

When it comes to maintaining or rebuilding your PowrTwin 5500 airless sprayer, having access to the right major components is essential. These parts form the backbone of your sprayer, from the motor and pump assemblies to the hydraulic system and cart frame, ensuring your equipment runs safely, efficiently, and reliably on every job. This page gathers all genuine Titan 5500 major components so you can find exactly what you need for repairs or upgrades.

Key Major Components for PowrTwin 5500

Here are the main parts included under the “Major Components” category:

- Motor / Pump Assembly — the heart of your 5500, combining the hydraulic motor with the fluid piston pump, including rod, cylinder, packings, and valves. This assembly powers the fluid delivery system and maintains high-pressure spray performance.

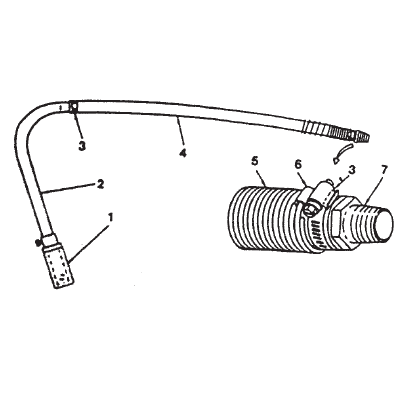

- Bleed Line Assembly with Valve — essential for safe depressurization, flushing, and maintenance of your sprayer’s hydraulic and fluid systems.

- Syphon Hose Assembly — suction hoses with rock-catchers for drawing fluid from buckets or drums efficiently.

These major components make it possible for the PowrTwin 5500 to perform at professional-grade levels, delivering reliable pressure, consistent flow, and smooth spray results.

Why Genuine Major Components Matter

- Durability and performance under heavy use — Genuine assemblies are designed to withstand high-pressure operation and abrasive coatings, reducing wear and prolonging equipment life.

- Reliable fluid delivery — Using the correct pump, hydraulic system, and manifold parts ensures even spray patterns and consistent pressure without leaks.

- Structural stability and safety — The cart assembly and mounts provide proper support for the motor and pump, preventing misalignment and unsafe operation.

- Simplified maintenance and repair — With standard OEM parts, replacing worn components or rebuilding the sprayer is straightforward, avoiding compatibility issues with aftermarket components.

- Safe depressurization — Bleed valves and lines designed to original specs prevent accidental fluid release during maintenance, protecting both the operator and the sprayer.

FAQs

1.Which parts are considered “major components” of the 5500 sprayer?

Major components include the Motor/Pump Assembly, Hydraulic System, Cart Assembly, Gas Convertokit, Outlet Manifold Filter Assembly, Bleed Line Assembly with Valve, and Syphon Hose Assembly.

2. Can I replace only the motor or pump without replacing the entire assembly?

Yes, individual repairs are possible if you use the OEM parts specified for the motor or pump. However, inspect all associated components (hydraulic lines, packings, seals) to ensure proper operation.

3. Why should I use only genuine Titan major components?

OEM parts are engineered to handle the 5500’s high-pressure operation safely and efficiently. Using aftermarket or incompatible parts can lead to leaks, reduced performance, or safety risks.

4. How often should major components be inspected or serviced?

Inspection frequency depends on usage. For frequent or heavy-duty operation, check hydraulic lines, pump packings, valves, and the cart assembly regularly. Perform a full overhaul when you notice performance loss, leaks, or wear on critical components.