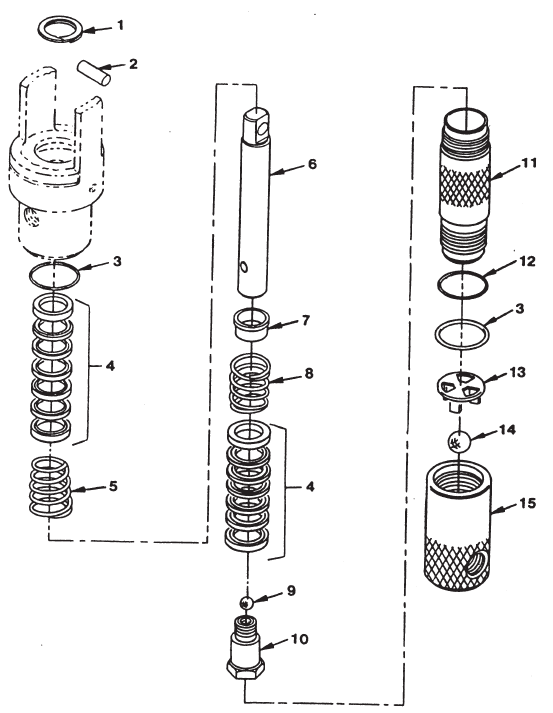

Part #: 143-019

Part #: 143-120

Part #: 145-031

Part #: 138-153A

Part #: 142-004

Part #: 143-127

Part #: 138-001

Part #: 142-003

Part #: 0509710

Part #: 143-945A

Part #: 143-822

Part #: 140-009

Part #: 145-032

Part #: 920-103

Part #: 143-998

Maintain the heart of your Titan PowrTwin 5500 airless sprayer with our premium selection of OEM replacement parts for the fluid pump. This essential system delivers consistent, high-pressure fluid flow for flawless finishes on everything from interior walls to exterior coatings. At AllTitanParts.com, we stock durable, direct-fit parts that restore peak performance, reduce leaks, and extend your equipment's lifespan, ideal for busy contractors prioritizing efficiency and reliability.

What does the PowrTwin 5500 fluid pump do? It pressurizes paint and coatings up to 3,000 PSI, ensuring even atomization and minimal overspray through its robust piston, valve, and sealing assembly. Regular part replacements prevent clogs and wear, keeping your jobs on schedule without unexpected downtime.

Our inventory covers every critical component, from seals and springs to rods and valves, all engineered for seamless compatibility and easy installation. Made from high-grade stainless steel, PTFE, and synthetic materials, these parts withstand abrasive materials and high-volume use.

Key parts available in this category include:

These parts are tailored for the PowrTwin 5500 and extend to compatible Titan sprayers like PowrLiner 550, PowrCoat 730, PowrTex 15-1 Heavy Mate, and Helix Hose systems. How can you tell if your fluid pump needs servicing? Watch for inconsistent flow, pressure fluctuations, or visible wear on O-rings—swapping in a repacking kit like the Titan 138-153A can resolve most issues quickly.

If you're wondering "how to repack a Titan PowrTwin 5500 fluid pump," use the 138-153A kit: disassemble the upper housing, replace packings and springs, lubricate, and reassemble in 45 minutes for renewed efficiency.

Investing in these fluid pump parts can boost output by 15-20% while cutting maintenance costs. Why replace the piston rod in a PowrTwin 5500? Its stainless steel build resists corrosion from solvents, ensuring thousands of hours of trouble-free pumping. Customers love the straightforward installs and immediate improvements in flow consistency—perfect for high-demand painting seasons.

Browse our full range today for competitive pricing, detailed diagrams, and fast delivery. Every part includes compatibility guides to match your setup.

The 138-153A repacking kit includes upper and lower packings, O-rings (like 145-031), springs (142-004 and 142-003), and a spring retainer (138-001) for comprehensive maintenance. It replaces older 0349-409 kits and restores sealing to prevent leaks, ideal for routine overhauls every 500 hours.

These parts fit the PowrTwin 5500 directly, plus PowrLiner 4950/550, PowrCoat 730, PowrTex 15-1 Heavy Mate, Elite E15, and SPEEFLO equivalents like PowrLiner 490 and PowrDriver. The stainless steel piston rod (replacing 143-117) ensures broad versatility across gas-powered airless systems.

Simple steps: Drain the pump, remove the upper assembly, slide the new retaining ring into the groove on the piston rod (143-127), secure with pliers, and test for stability. It takes 10-15 minutes and secures components against vibration—always wear gloves to avoid pinching.

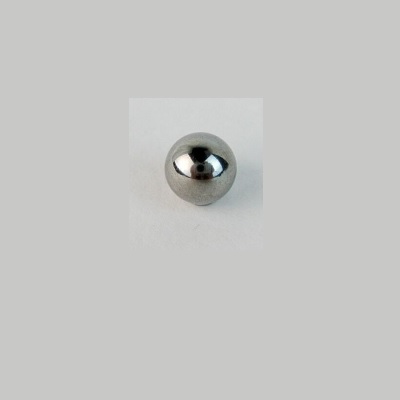

This 7/16" tungsten carbide ball (replacing 0349414 or 138-225) acts as a one-way check valve, allowing fluid to exit under pressure while preventing backflow. Paired with the 145-032 ball cage, it maintains consistent 3,000 PSI output and resists wear from abrasive paints.

Maintenance advice: Inspect and replace PTFE O-rings every 250-500 operating hours or at signs of swelling/leaks from chemical exposure. The 145-031 provides superior sealing over rubber alternatives, extending pump life when combined with the 138-153A repacking kit.