Subcategories

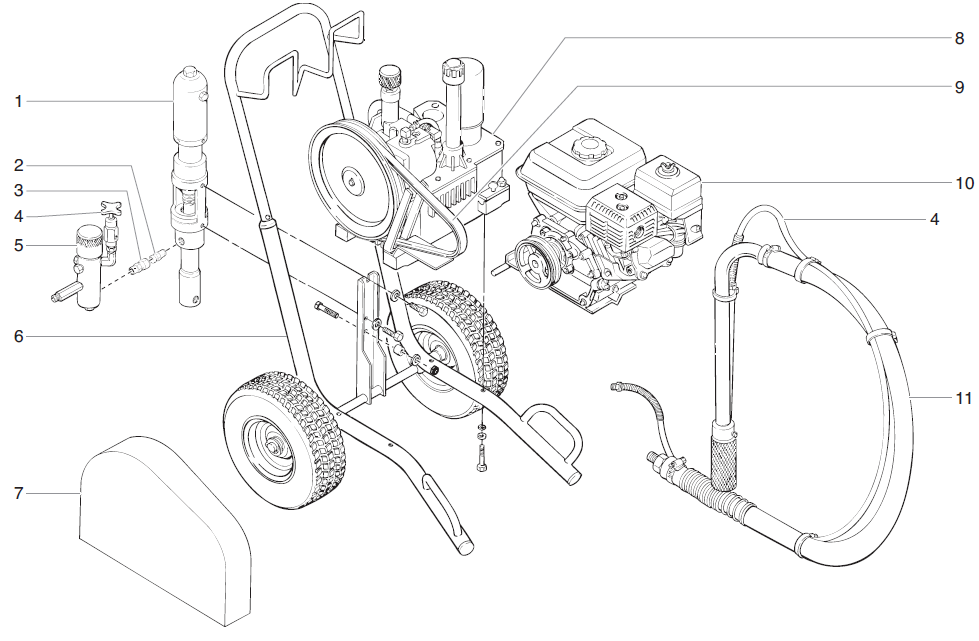

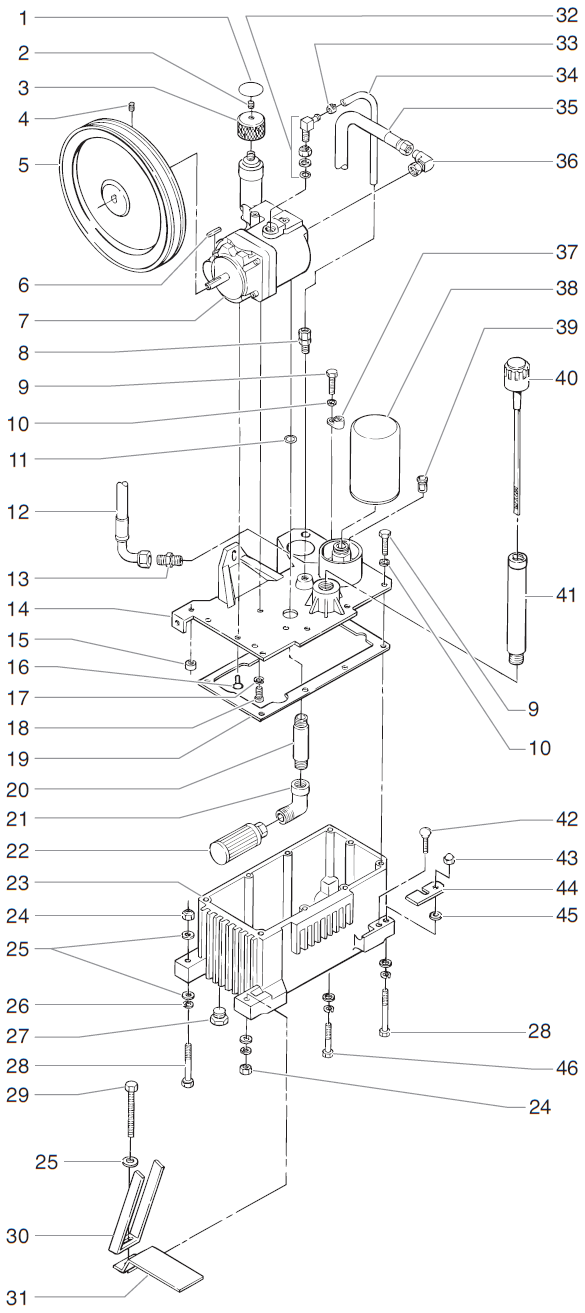

PowrTwin 4900GH Main Assembly

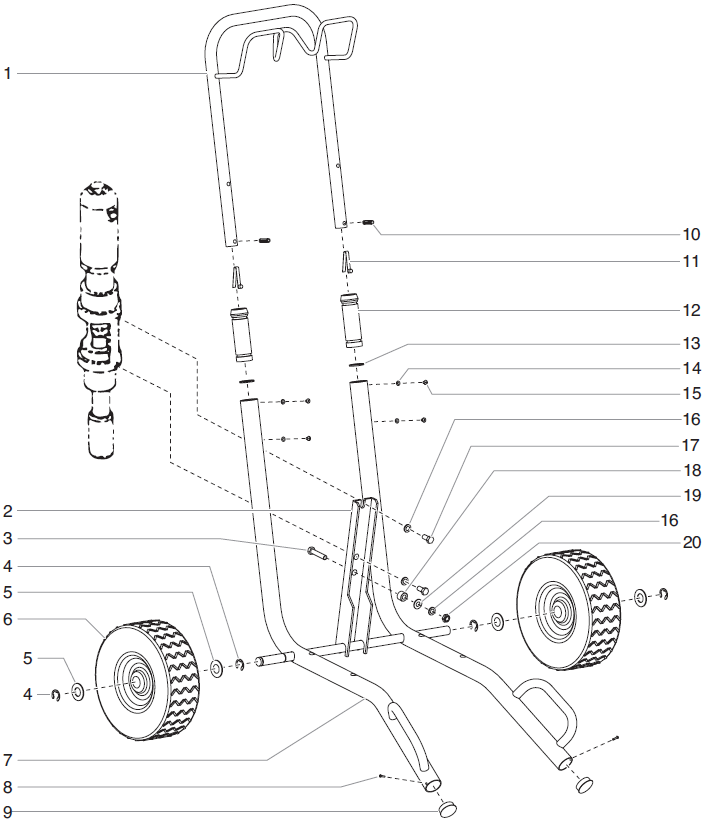

PowrTwin 4900GH Cart Assembly

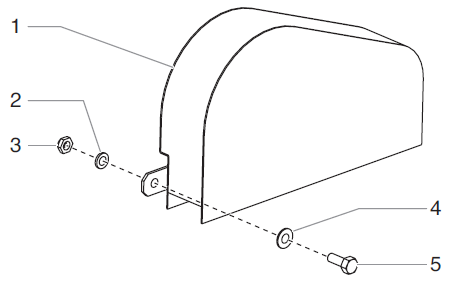

PowrTwin 4900GH Belt Guard Assembly

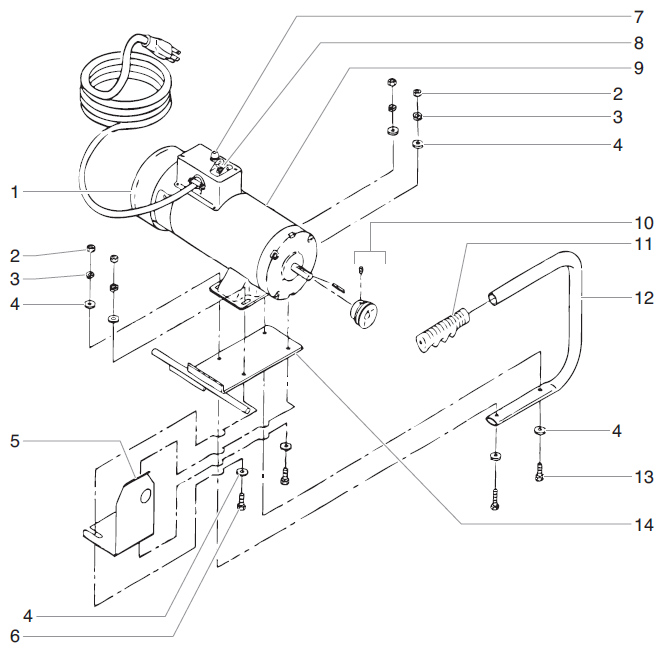

PowrTwin 4900GH DC - Electric Convertokits

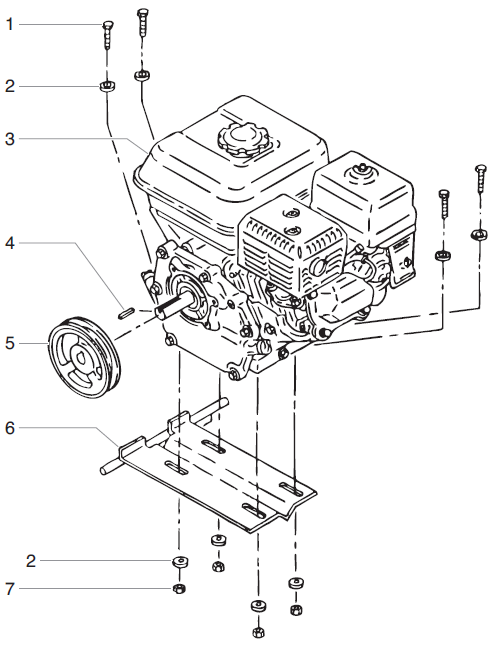

PowrTwin 4900GH Gas Convertokit

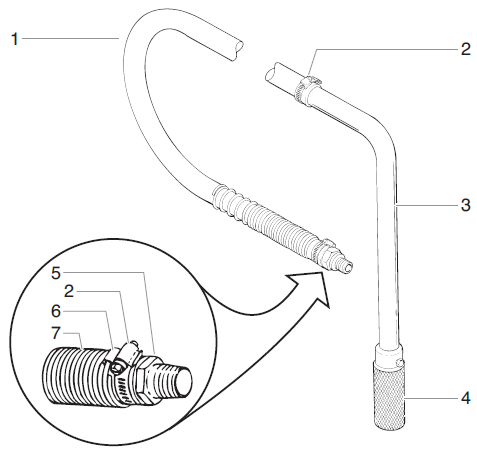

PowrTwin 4900GH Siphon Hose Assembly

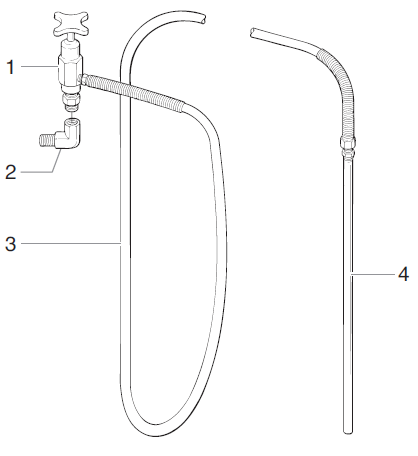

PowrTwin 4900GH Bleed Hose Assembly With Valve

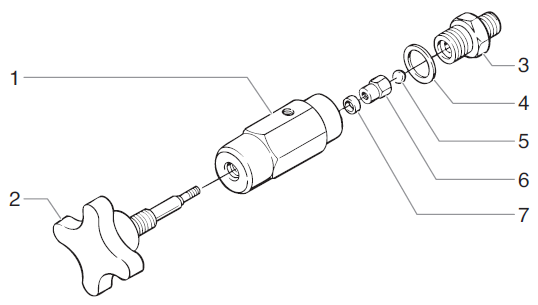

PowrTwin 4900GH Bleed Valve Assembly

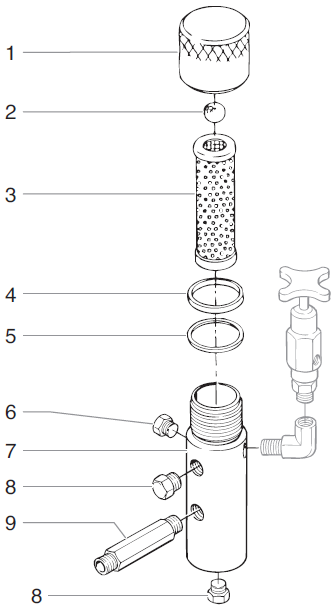

PowrTwin 4900GH Filter Assembly

PowrTwin 4900GH Hydraulic System

PowrTwin 4900GH Hydraulic Motor

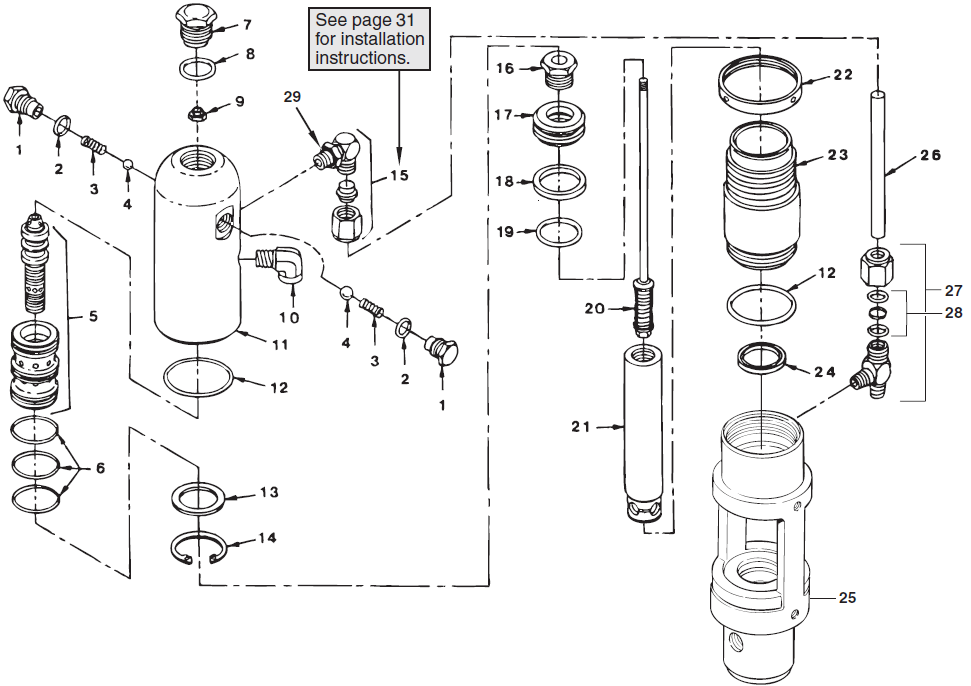

PowrTwin 4900GH Fluid Section

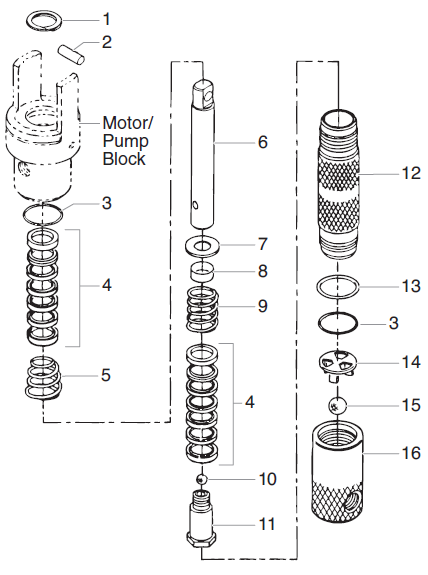

PowrTwin 4900GH Manifold Assemblies

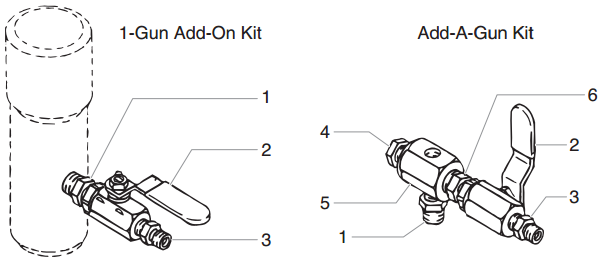

PowrTwin 4900GH Accessories

NEW PRODUCTS FOR FEBRUARY - POWRTWIN 4900GH

The PowrTwin 4900GH is a high-performance, gas-powered hydraulic airless sprayer designed for contractors who need reliable power, durability, and the ability to handle demanding coatings on large-scale projects. Built with a rugged hydraulic system, a high-output motor, and a precision fluid section, the 4900GH delivers strong performance even with heavy materials.

Its modular design also makes maintenance easier, with key assemblies like the filter system, hydraulic motor, siphon hose, bleed valve, and fluid section all individually serviceable.

Whether used for residential repaints or commercial and industrial jobs, the PowrTwin 4900GH offers dependable pressure, smooth spraying, and long service life.

Equipped with a robust gas engine that provides consistent pressure and power for all types of coatings, even high-viscosity materials.

The PowrTwin 4900GH uses a proven hydraulic system that delivers smooth, constant pressure and reduces pulsation for uniform spray patterns.

The stainless-steel fluid section is engineered for durability, long life, and compatibility with a wide range of coatings.

Components—such as the filter assembly,-siphon-hose-assembly, bleed valve, hydraulic motor, and gas convertokit are easily removable for cleaning, repair, or replacement.

Designed to spray latex, primers, acrylics, elastomerics, block fillers, epoxies, and more.

Ideal for contractors who need extended run times, high material output, and the ability to spray longer hose lengths.

The filter assembly removes debris and contaminants before they enter the pump and hose. Regular cleaning is recommended daily or whenever material flow becomes inconsistent. The internal screen should be replaced if damaged or clogged.

The bleed valve assembly helps release trapped air from the hydraulic pump and fluid section during priming. If the sprayer fails to prime or pressure fluctuates, checking the bleed valve for blockage or worn seals is essential.

The hydraulic motor drives the pump with consistent power, reducing pulsation and improving spray quality. If you notice slow cycling or poor pressure, it may indicate worn seals or internal hydraulic leaks within the motor assembly.

The fluid section is the heart of the sprayer; it hoses the piston, packings, rods, and cylinders that pressurize paint. Replacing packings and lubricating this section ensures long pump life and prevents pressure loss.

The siphon hose pulls material from the bucket into the sprayer. Cracks, clogs, hardened hoses, or air leaks can cause priming issues or low pressure. Replace the hose if it appears stiff, damaged, or heavily worn.