Subcategories

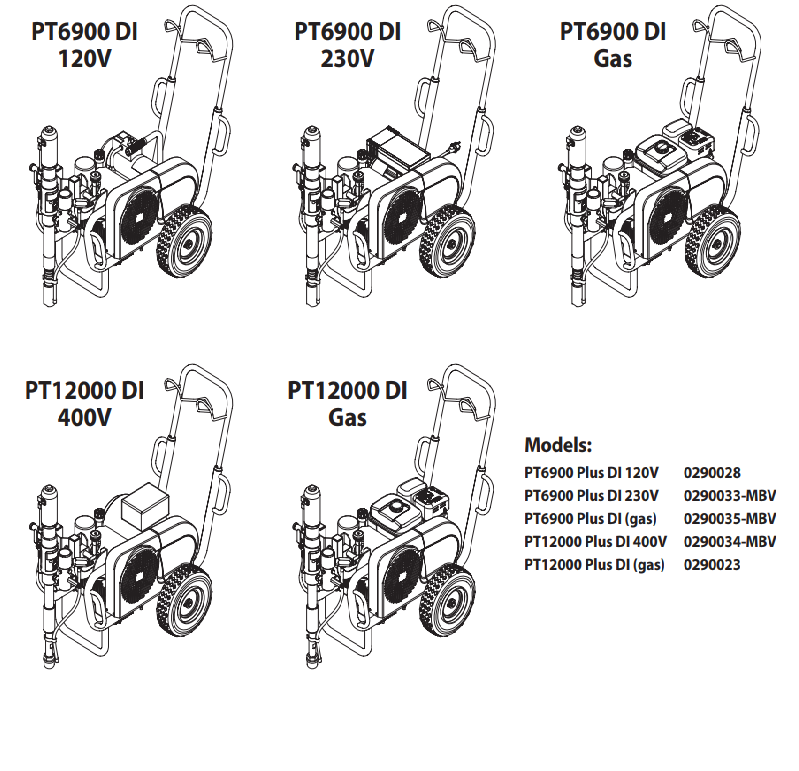

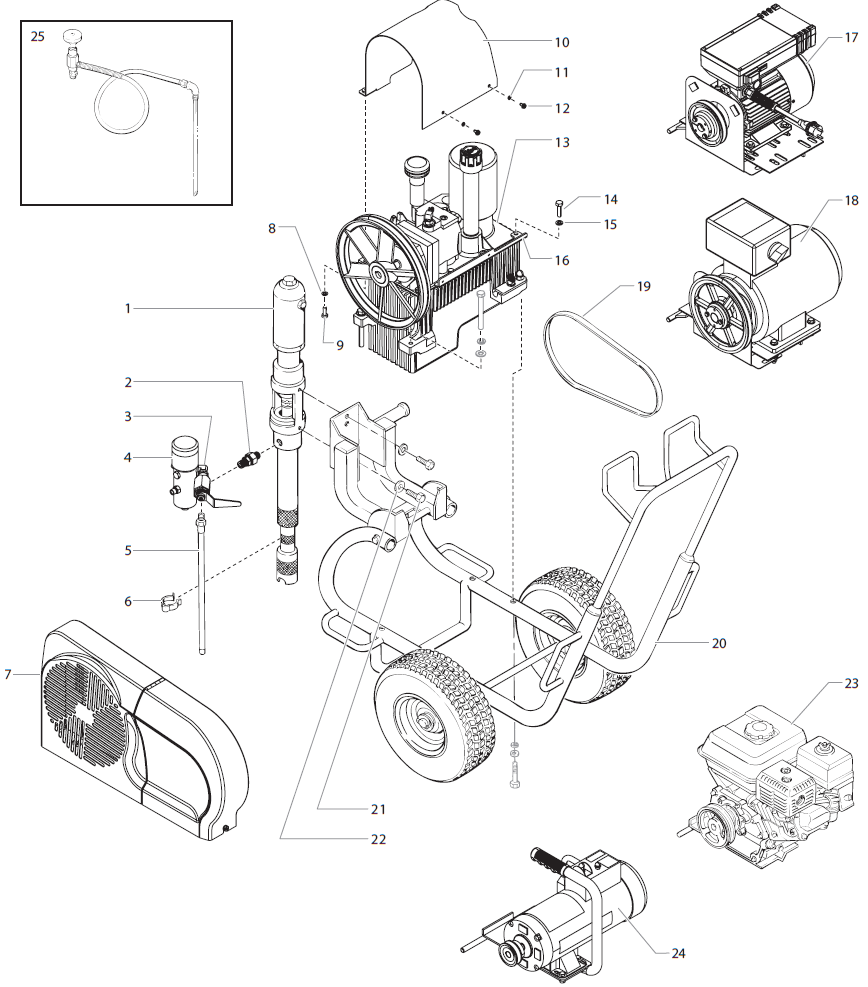

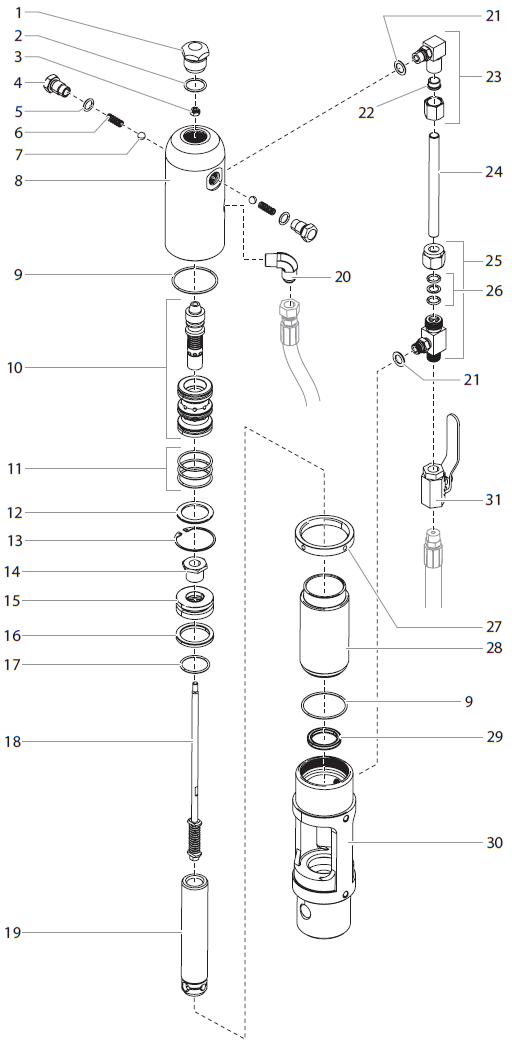

PowrTwin 6900 Plus DI Main Assembly

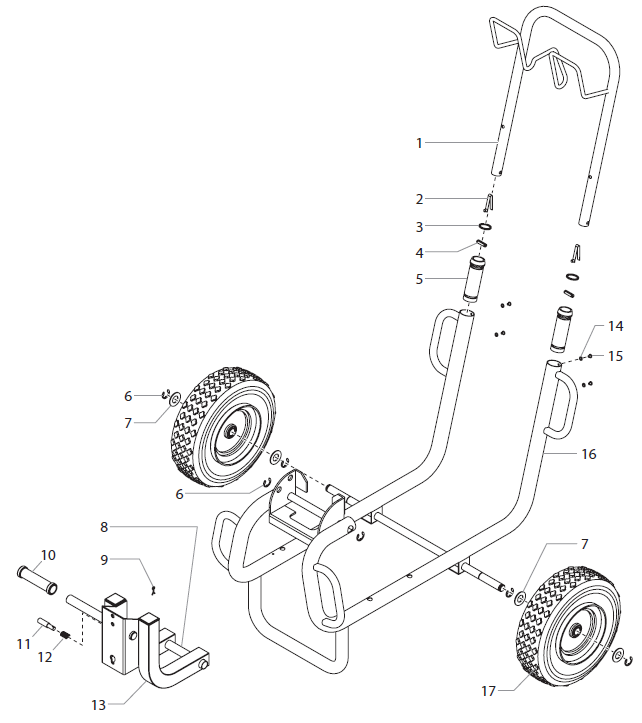

PowrTwin 6900 Plus DI Cart Assembly

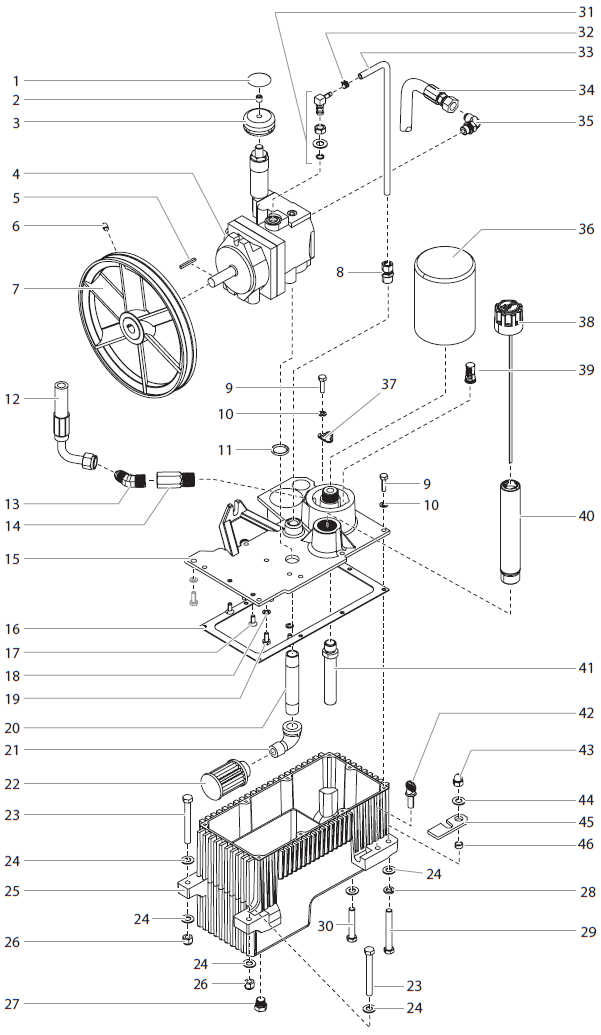

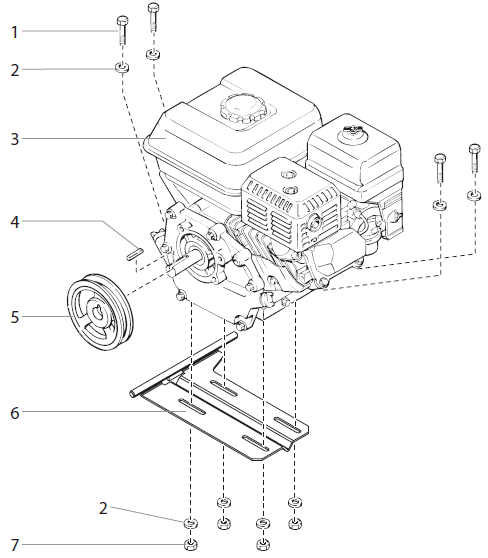

PowrTwin 6900 Plus DI Hydraulic system

PowrTwin 6900 Plus DI Hydraulic motor

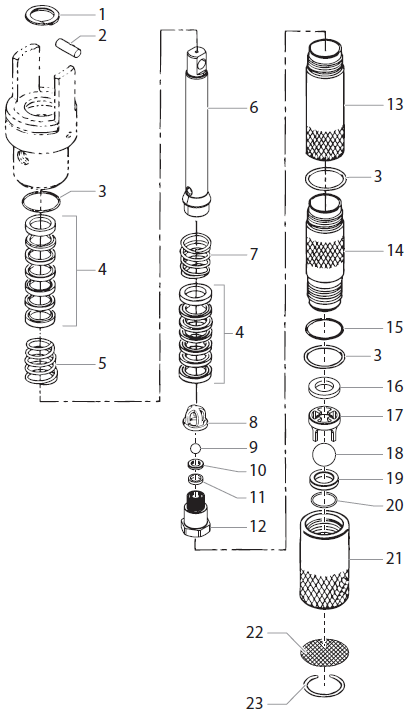

PowrTwin 6900 Plus DI Fluid Section

PowrTwin 6900 Plus DI Gas convertokit

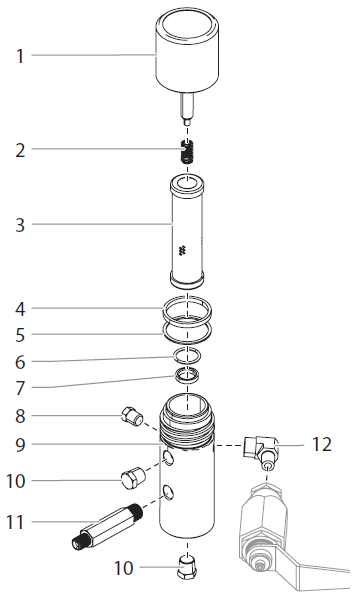

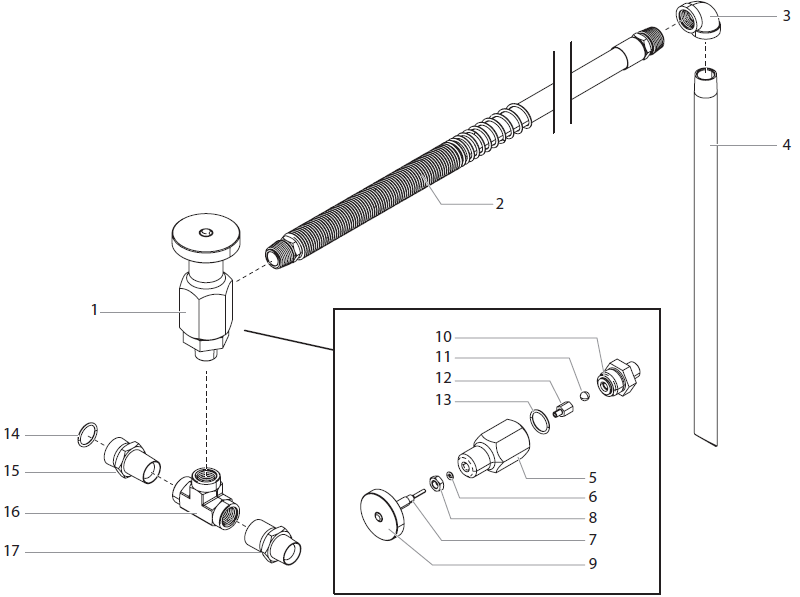

PowrTwin 6900 Plus DI High pressure filter

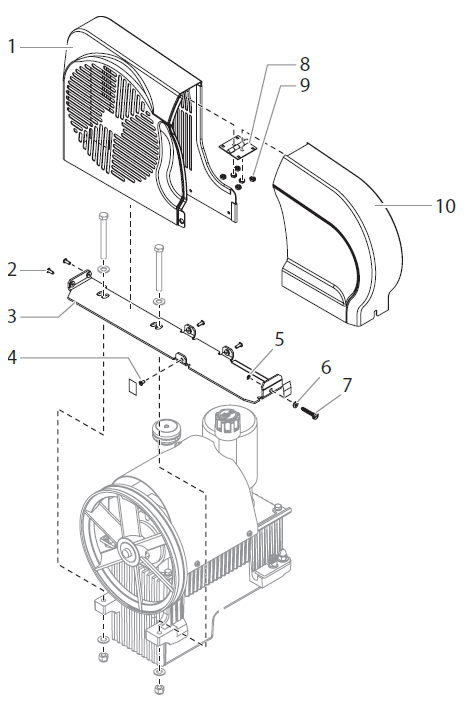

PowrTwin 6900 Plus DI Belt Guard Assembly

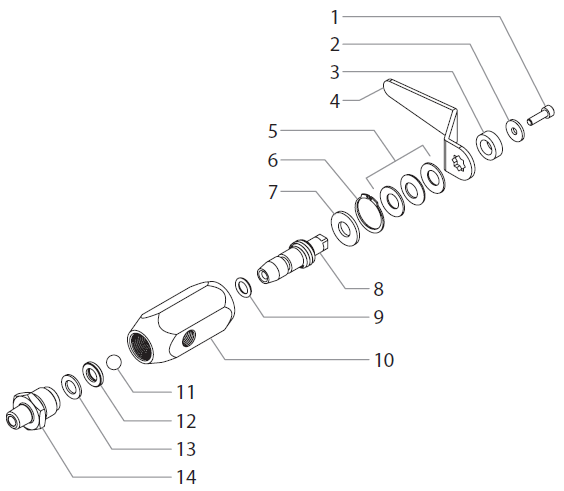

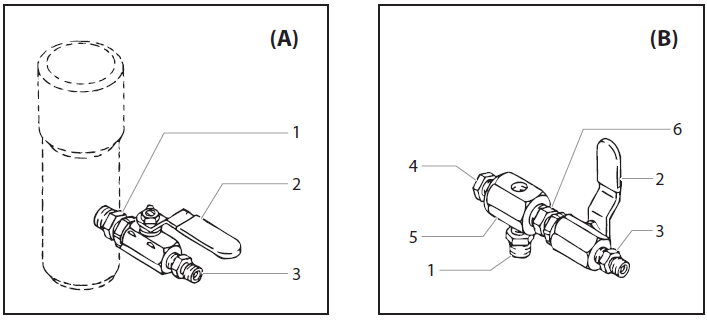

PowrTwin 6900 Plus DI Bleed Valve Assembly

PowrTwin 6900 Plus DI Bleed Valve Assembly Heavy Materials

PowrTwin 6900 Plus DI Gun Manifold Assemblies (Optional)

Accessories

NEW PRODUCTS FOR FEBRUARY - POWRTWIN 6900 PLUS DI

The PowrTwin 6900 Plus DI is a heavy-duty, direct-immersion airless sprayer engineered for contractors who demand exceptional durability, high output, and reliable performance on the toughest job sites. Designed to handle thick coatings and continuous spray cycles, this unit is ideal for large-scale residential, commercial, and industrial applications.

Built with a rugged hydraulic system, powerful gas engine, and precision fluid section, the PowrTwin 6900 Plus DI ensures consistent pressure, smooth spray patterns, and long-lasting operation. Whether you’re applying latex, primers, block fillers, or elastomerics, this sprayer delivers professional-grade results every time.

Its modular design includes easily replaceable components such as the Main Assembly, Hydraulic System, Fluid Section, Cart Assembly, High-Pressure Filter, Hydraulic Motor, Gas Convertor Kit, and Belt Guard Assembly, making maintenance simple and cost-effective.

The PowrTwin 6900 Plus DI is engineered for large-scale professional use, including:

Whether you’re tackling multi-room projects or large commercial structures, the PowrTwin 6900 Plus DI offers the reliability and power you need to complete the job efficiently.

Yes. AllTitanParts provides individual components, complete kits, and assembly-specific parts, so you only need to purchase exactly what you require.

Common signs include inconsistent spray patterns, Pressure fluctuations, and leaking around the piston or packing. The fluid section contains key wear items such as seals, springs, and the piston rod, which are designed for periodic replacement.

The high-pressure filter prevents debris from reaching the spray gun or tip.

A damaged or clogged filter can cause poor spray quality, frequent tip clogging,s and pressure loss. Replacing the filter element regularly ensures optimal performance.

Yes. The Gas Convertor Kit allows quick and easy conversion. This is ideal for job sites without electrical access.

You may need to service the hydraulic system if you notice loss of spray pressure, Harsh running sound, and overheating. Components such as the hydraulic motor, pump, and seals should be inspected during maintenance.