Subcategories

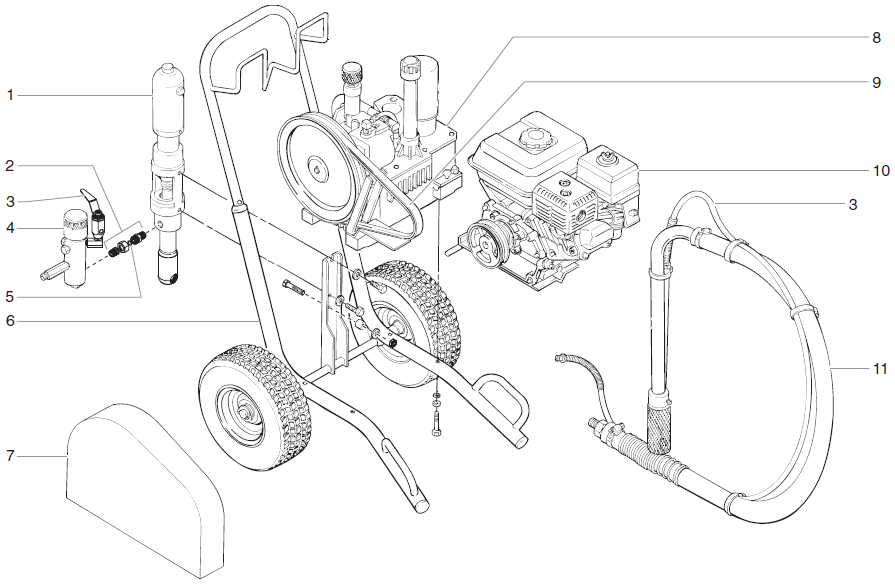

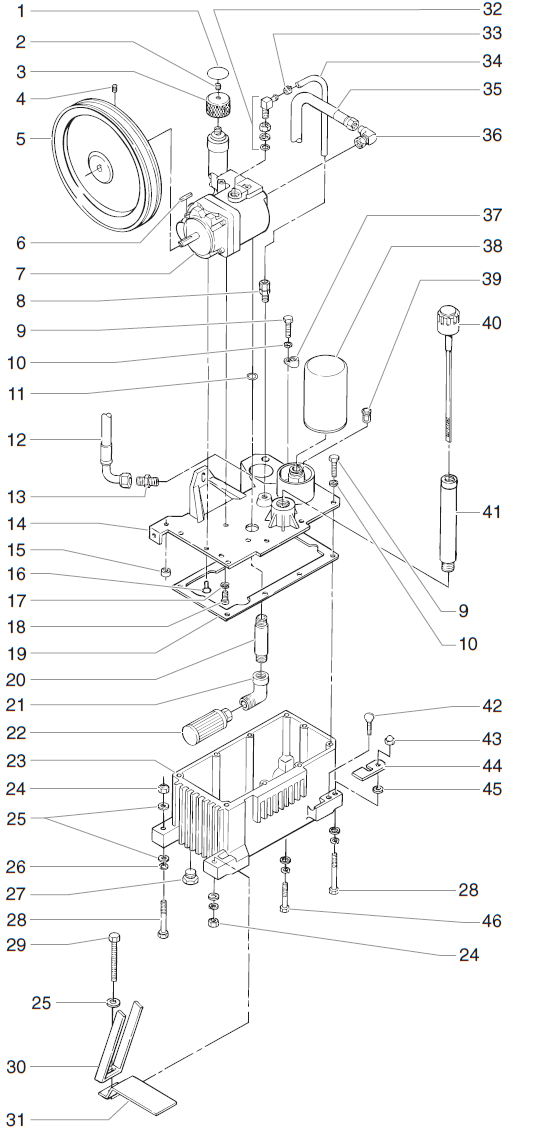

PowrTwin 4900XLT Main Assembly Parts

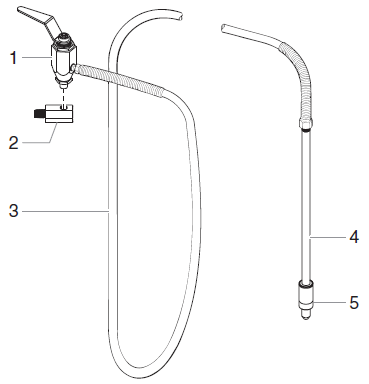

PowrTwin 4900XLT Bleed Hose Assembly With Valve Parts

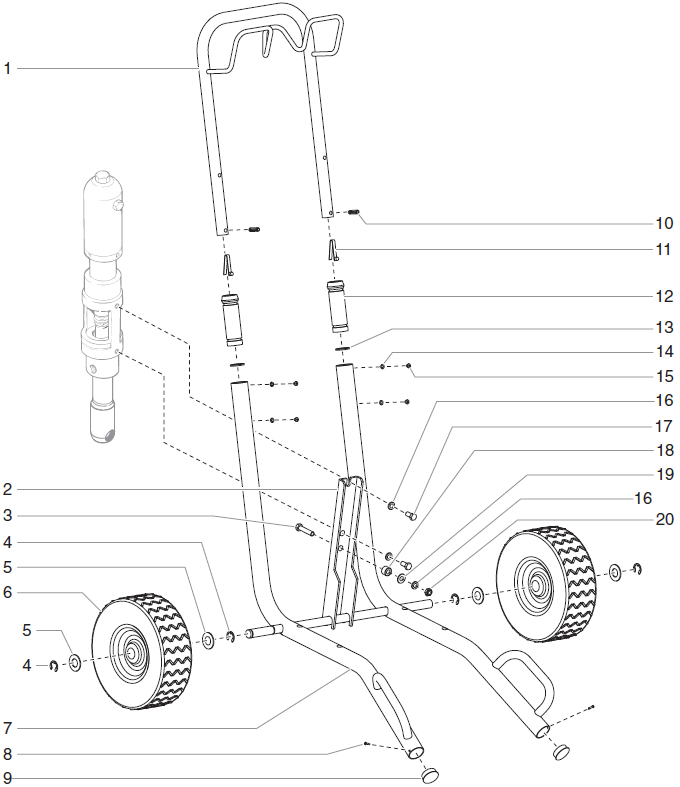

PowrTwin 4900XLT Cart Assembly Parts

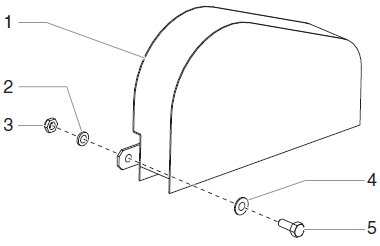

PowrTwin 4900XLT Belt Guard Assembly Parts

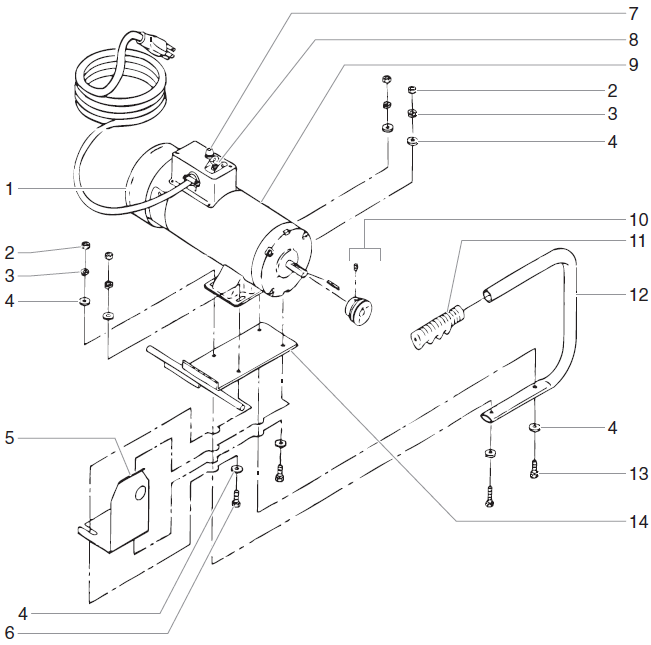

PowrTwin 4900XLT DC Electric Convertokits Parts

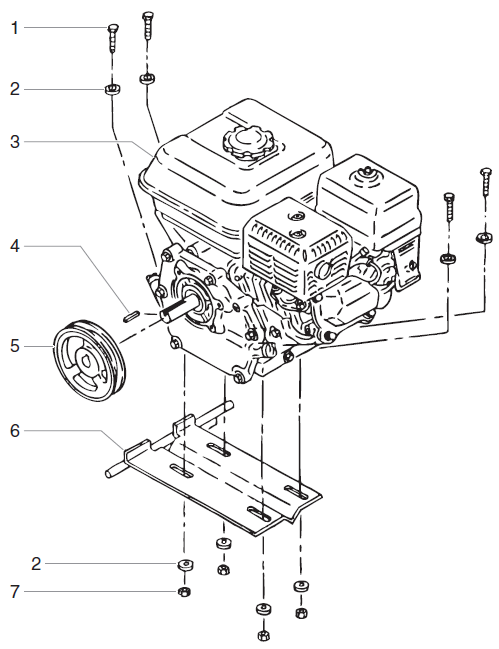

PowrTwin 4900XLT Gas Convertokit Parts

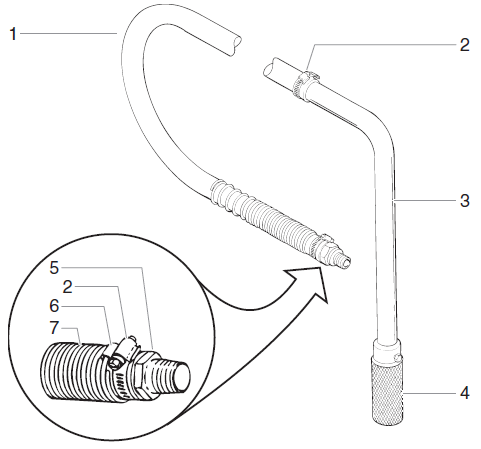

PowrTwin 4900XLT Siphon Hose Assembly Parts

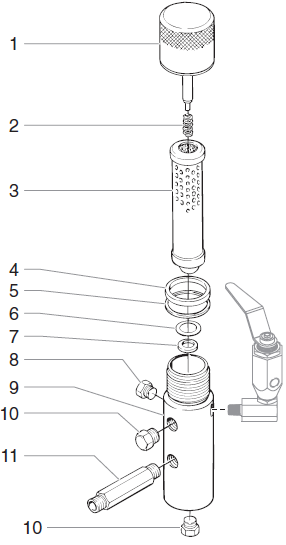

PowrTwin 4900XLT Bleed Valve Assembly Parts

PowrTwin 4900XLT Filter Assembly Parts

PowrTwin 4900XLT Hydraulic System Parts

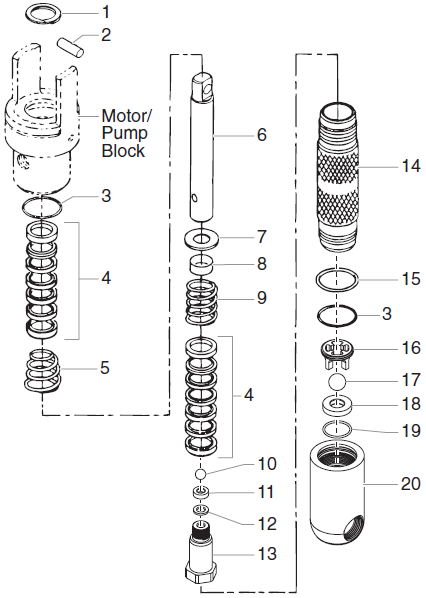

PowrTwin 4900 XLT Hydraulic Motor Parts

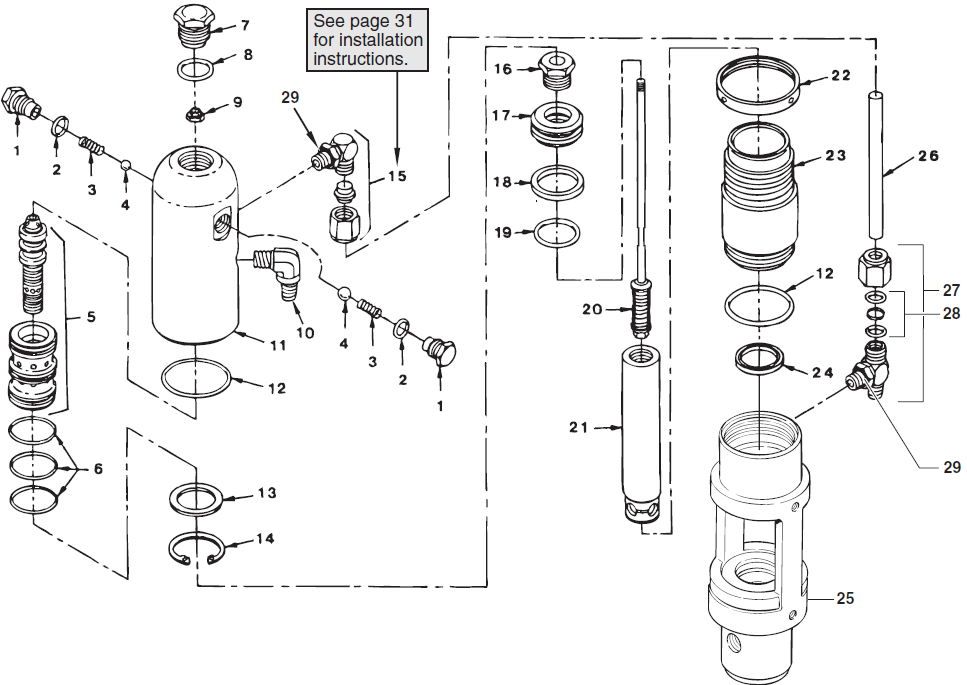

PowrTwin 4900XLT Fluid Section Parts

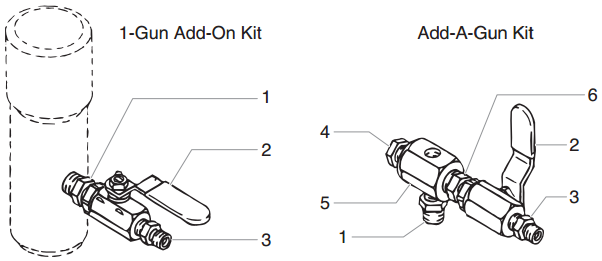

PowrTwin 4900XLT Gun Manifold Assemblies Parts

PowrLiner 4900xlt Accessories Parts

NEW PRODUCTS FOR FEBRUARY - POWRTWIN 4900XLT

The PowrTwin 4900XLT is a heavy-duty hydraulic airless sprayer engineered for professional contractors and serious painting crews. Built on the proven PowrTwin platform, the 4900XLT combines a powerful hydraulic drive with a robust construction to handle a wide range of coatings from latex and primers to heavy block fillers and elastomerics. Its design emphasizes durability, field-serviceability, and stable pressure output for consistent spray performance even under demanding jobsite conditions.

With modular components such as a serviceable fluid section, hydraulic motor/pump block, bleed and siphon hardware, and optional gas or electric drive configurations, the 4900XLT is intended for long-term use and maintenance flexibility. It’s suited for high-volume applications, large surface coverage, and materials that require steady, high pressure.

The fluid section houses the piston, seals, valves, and cylinders that pressurize and move coating material. It’s the heart of the sprayer; any wear, seal damage, or contamination here directly affects pressure output, spray consistency, and overall reliability. Regular inspection, correct cleaning, and timely replacement of seals or packings help maintain spray quality and prolong pump life.

The hydraulic motor block converts engine (or motor) power into hydraulic pressure that drives the fluid section. A robust motor/pump block ensures smooth cycling, steady pressure, and minimal pulsation. If this block suffers wear, leaks, or internal damage, spray performance will degrade, making regular maintenance essential.

The bleed or flush valve is used during priming, system startup, shutdown, or cleanup. It allows trapped air, residual paint, or solvent to be released from the fluid passage before spraying or after cleaning. This helps ensure proper priming, prevent airlocks, and maintain consistent pressure. Skipping bleed/flush procedures may result in poor spray performance or damage.

The inlet/siphon hose draws paint or coating from buckets to the pump. Over time, the hose can become stiff, clogged, cracked, or develop leaks, especially when used with aggressive coatings or solvents. If the sprayer has trouble priming, shows irregular flow, or has pressure loss, inspect the inlet hose. Replace if damaged, discolored, hardened, or leaking to maintain reliable suction and consistent material feed.

Regular maintenance, including cleaning or replacing the fluid section seals, checking hydraulic fluid and motor block, cleaning filters and valves, inspecting hoses, and following priming/bleed procedures, significantly extends the life of the sprayer.

Neglecting maintenance may result in pressure loss, sealing failures, uneven spray, or premature wear, especially when using heavy or abrasive coatings. Maintenance ensures consistent performance, reduces downtime, and protects the unit’s service life.