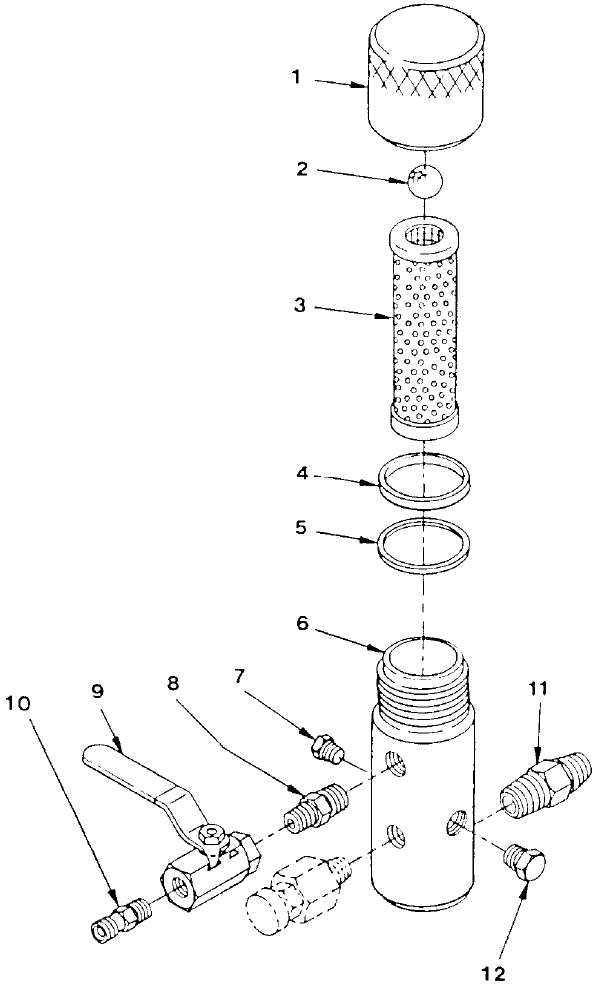

PowrTwin 3500 – Outlet Manifold Filter Assembly with Check Valve

Ensure your PowrTwin 3500 sprayer maintains clean fluid flow and safe system integrity with our genuine Outlet Manifold Filter Assembly with Check Valve components. This sub-category covers the manifold block, filter element and check valve assembly that manage the fluid outlet path—critical for controlling flow, preventing contamination and protecting downstream nozzles and guns.

Why Choose Genuine Outlet Manifold Filter Assembly Parts?

- Specifically engineered for the PowrTwin 3500 series, ensuring correct porting, pressure rating (up to 5 000 psi as per manufacturer spec) and compatibility with the machine’s outlet system.

- The filter element traps debris and contaminants, while the check valve prevents back-flow—both essential for preserving finish quality and avoiding gun/clog issues.

- Using OEM manifold-filter-check valve assemblies helps avoid mis-fit, incorrect flow paths or unsafe pressure behaviour which might compromise performance or safety.

- Compatible components simplify service, reduce downtime, and maintain performance reliability.

- Documentation shows that the outlet manifold filter assembly (Part No. 920-560) is listed under “Outlet Accessories” in the service manual for the PowrTwin 3500.

Our Range of Outlet Manifold Filter Assembly Components

Explore the key items listed in this sub-category (each item should link to its product page for full specs and purchase):

Pro Tip: If you notice flow restrictions, frequent gun clogging, or paint overspray issues, inspect the outlet manifold filter assembly and check valve—often a contaminated filter or faulty check valve is the root cause.

How to Choose the Right Outlet Manifold Filter Assembly Part

Here’s how to select the correct part for your PowrTwin 3500:

- Identify the symptom: If fluid output seems restricted, filters get clogged, or you detect back-flow or inconsistent pressure at the gun, the manifold filter & check valve assembly might be compromised.

- Confirm your model & part number: Ensure you’re working with the PowrTwin 3500 and referencing the correct assembly (e.g., 920-560 in the manual).

- Decide full assembly vs element only: If the filter housing is fine but the element is clogged, you may only need the element (# 920-004 or alternatives). If the housing or check valve is damaged, replace the full assembly.

- Follow proper maintenance: Filters should be cleaned/changed regularly based on paint material and usage. Check valves should be inspected for correct seating and operation.

- Install correctly: Use appropriate torques, ensure gaskets are seated, and follow manufacturer instructions to maintain correct pressure rating and flow path integrity.

FAQs

What does the “Outlet Manifold Filter Assembly with Check Valve” category cover for the PowrTwin 3500?

This category includes the manifold block, filter element (various mesh sizes), check valve/ball valve assembly, caps, gaskets and associated hardware that manage fluid outlet flow and protect downstream components.

Why is the manifold filter with check valve important on the PowrTwin 3500 sprayer?

Because the fluid outlet path must be free of debris, deliver stable flow, and avoid back-flow or contamination. The filter removes particles; the check valve ensures directional flow and prevents reverse pressure — both critical for consistent finish quality.

How often should I replace the filter element or check valve in this assembly?

Replacement frequency depends on usage, material thickness and job environment. If you spray heavy coatings, inspect or replace the element more frequently. Check the filter element for clogging, look for flow reduction, and test the check valve for proper seating.

Can I use a generic filter or check valve instead of the genuine assembly?

Using non-OEM parts may reduce reliability, compromise pressure rating, or lead to misfit and premature wear. Because this assembly carries high pressure and is part of the critical outlet system, genuine parts are strongly recommended.

What mesh size should I choose for the filter element (50-mesh, 100-mesh, or 5-mesh)?

- Use 50-mesh (# 920-004) for standard coatings and general service.

- Use 100-mesh (# 920-005) if spraying very fine coatings where particles must be minimized.

- Use 5-mesh (# 920-001) for heavy or coarse materials where a larger mesh may help maintain flow yet still provide protection. Always balance filtration with fluid throughput.

Ready to Replace Your Outlet Manifold Filter Assembly?

Browse our full collection of PowrTwin 3500 manifold-filter assemblies and check valve components above and select the exact part you need. If you’re unsure which mesh size or configuration fits your machine, contact our support team — we’ll help you determine the correct part and keep your sprayer flowing cleanly and safely.