Subcategories

NEW PRODUCTS FOR FEBRUARY - POWRCOAT 1045

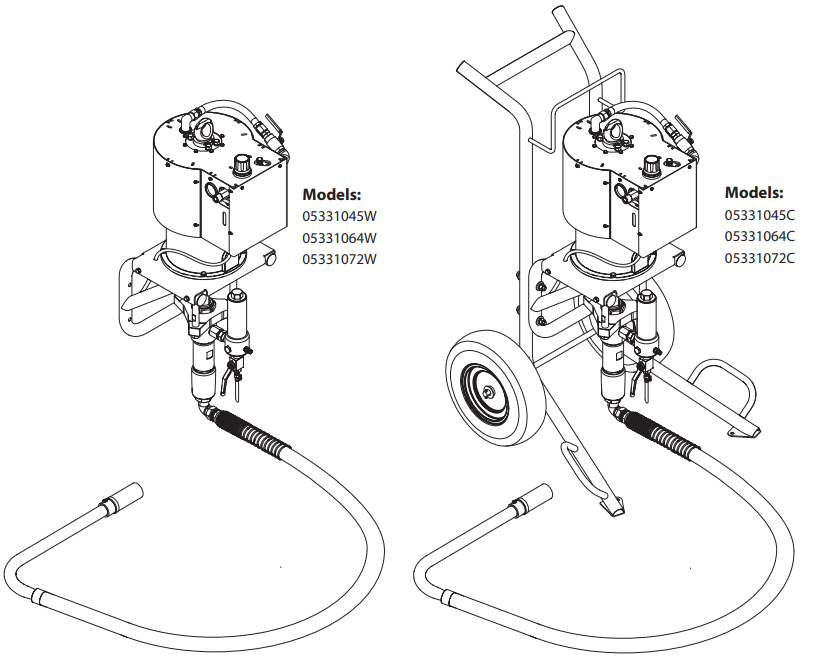

The PowrCoat 1045 is a heavy-duty industrial airless coating system engineered for extreme production demands and continuous operation. Designed as a wall-mount sprayer, the PowrCoat 1045 delivers exceptionally high material flow, stable pressure control, and consistent spray performance for the toughest protective and industrial coatings.

Built with a powerful air motor, precision fluid delivery system, and advanced filtration and lubrication components, the PowrCoat 1045 is ideal for fixed spray installations where reliability, efficiency, and minimal downtime are critical.

The main assembly integrates the air motor, fluid pump, high-pressure filter, and automatic filter-lubricator-regulator (FLR) system. Together, these components ensure stable pressure control, consistent material flow, and reliable high-pressure spraying performance.

The wall mount assembly securely supports the sprayer, reduces floor space usage, and minimizes vibration during operation. Proper installation enhances system stability, facilitates maintenance access, and ensures the correct alignment between the air motor and fluid pump.

The air motor assembly converts compressed air into a mechanical force that drives the fluid pump. Correct air pressure regulation and lubrication are critical to achieving smooth stroke operation, consistent pressure output, and extended motor seal life.

The fluid pump delivers coating material at high pressure, while the high-pressure filter removes contaminants before the material reaches the spray gun. Routine inspection and replacement of worn seals, packings, and filter elements prevent pressure loss, uneven spray patterns, and premature component failure.

The automatic FLR assembly conditions incoming air by filtering moisture and debris, regulating air pressure, and supplying lubrication to the air motor. Proper FLR adjustment protects internal components, ensures consistent system performance, and reduces downtime caused by air-related issues.