Subcategories

NEW PRODUCTS FOR FEBRUARY - POWRCOAT 1064

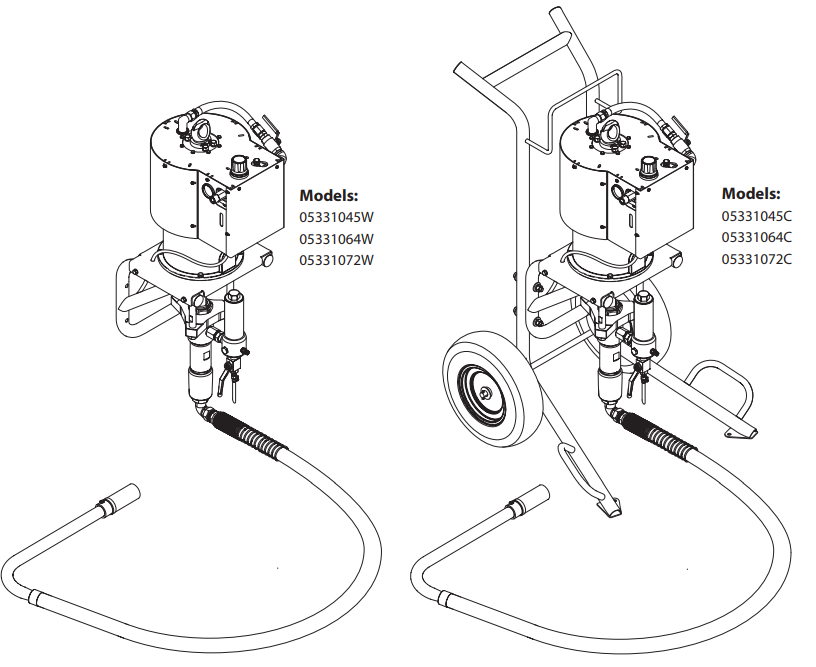

The PowrCoat 1064 is an ultra-high capacity industrial airless coating system engineered for maximum production output and continuous-duty operation. Designed as a wall-mount airless sprayer, the PowrCoat 1064 delivers exceptional material flow, stable pressure control, and consistent atomization for the most demanding protective and industrial coating applications.

Built with a powerful air motor, heavy-duty pumping system, and advanced filtration and lubrication components, the PowrCoat 1064 is ideal for fixed spray installations where reliability, efficiency, and long service life are essential.

The PowrCoat 1064 is designed for extremely high-viscosity and heavy industrial coatings, including epoxies, elastomerics, fireproofing materials, and protective coatings.

Yes, the PowrCoat 1064 is engineered for continuous, high-output operation in fixed wall-mount production environments.

The automatic lubricator minimizes friction and internal wear, helping extend the service life of the air motor and pumping components.

High-pressure filters should be inspected regularly and cleaned or replaced when material buildup or pressure drop is observed.

Yes, the PowrCoat 1064 supports multi-gun setups, making it ideal for high-production spray lines and large-scale coating operations.