Presenting the AlltitanParts EPX2255 Advantage Series Piston Pump

The ultimate expression of power and effectiveness in fluid management. The innovative EPX2255 Advantage Piston Pump sets a new standard for industrial fluid control productivity and durability. Titan Parts was meticulously designed in every way.

The EPX2255 Pump is engineered to perform very well in challenging conditions. Even under the most trying circumstances, its unmatched endurance guarantees flawless operation. Precise and consistent fluid flow is provided by contemporary piston design and assembly components, increasing productivity and decreasing failure rates.

The efficiency of the EPX2255 is what sets it apart. Thanks to upgraded energy-saving features, it provides an affordable solution to your fluid control issues by optimizing resource consumption without sacrificing production.

Reach new levels of productivity and efficiency in your job. Purchase the EPX2255 Advantage Series Piston Pump from AlltitanParts right now, and see how your business procedures are affected.

FAQ’s

1. Installation Issue: Why won’t my EPX2255 draw paint during initial setup?

This is one of the most common challenges during first-time installation.

Possible Causes & Solutions:

- Air leak in the Suction Set Assembly: Check the suction hose, clamps, and inlet screen for cracks or loose fittings.

- Clogged inlet filter: Remove the filter from the Suction Set Assembly and clean thoroughly.

- Prime/Spray valve not in PRIME position: Always switch to PRIME for 30–60 seconds to purge air.

- Material too thick: If using heavy coatings, thin slightly per manufacturer recommendations.

2. Configuration Issue: Why is my pump losing pressure during spraying?

Pressure drop usually indicates an issue in the Fluid Section Assembly or spray-tip setup.

Quick Fixes:

- Ensure your spray tip does not exceed 0.021 inches (maximum for the EPX2255).

- Clean the manifold filter—a clogged filter restricts pressure.

- Inspect packings in the Fluid Section Assembly; worn packings cause pressure loss and require repacking.

- Reduce hose length if exceeding 300 ft or upgrade to a larger diameter hose.

- Make sure the pressure adjustment knob is turned up adequately.

3. Spraying Performance Issue: Why is the spray pattern sputtering or pulsing?

This problem commonly comes from inconsistent material flow.

Troubleshooting Steps:

- Refill material bucket—low levels cause air to enter the system.

- Inspect the Suction Set Assembly for cracks or air leaks.

- Clean the gun filter and in-line filter (located in the fluid section path).

- Ensure the suction tube is fully submerged and not drawing air.

- Remove the spray tip, clean with solvent, and test flow without the tip installed.

4. Component Leakage Issue: Why is paint leaking around the Fluid Section or piston area?

Leakage indicates internal wear in the Fluid Section Assembly.

How to Fix It:

- Replace worn upper and lower packings using the correct Titan packing kit.

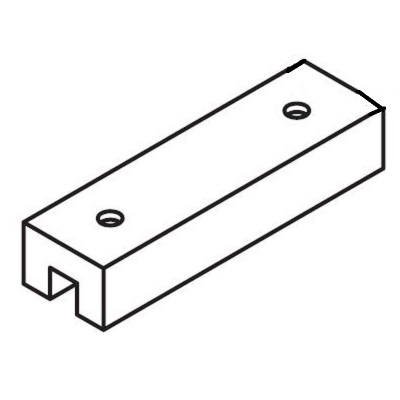

- Make sure packings are installed with correct orientation (as shown in the Fluid Section diagram).

- Lubricate the piston rod with Titan pump conditioner after cleaning.

- Check the piston rod for scoring; if damaged, replace before installing new packings.

5. Operation Issue: Why won’t my EPX2255 reach full pressure even though the motor is running?

This issue may involve the Motor Assembly, Gear Box Assembly, or internal fluid system.

Solutions:

- Inspect the gear box for unusual noise or resistance; worn gears reduce pressure output.

- Remove the spray tip and test pressure—if it increases, the tip is clogged or worn.

- Check the motor brush assembly for wear (if equipped) and replace if necessary.

- Ensure the stand or cart assembly is placed on level ground; vibration during use may impact motor load.

- Clean the manifold, inlet, and outlet filters to restore full flow.