Part #: 431-042

Part #: 192-228

Part #: 448-243

Part #: 860-520

Part #: 858-621

Part #: 858-624

Part #: 449-605

Part #: 472-500

Part #: 448-208

Part #: 759-456

Part #: 0509285

Part #: 448-213

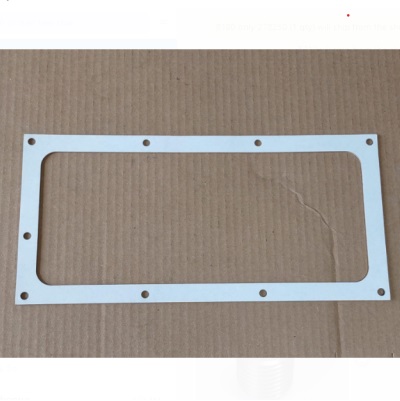

Part #: 941-555

Part #: 448-235

Part #: 192-050

Part #: 325-031

Part #: 858-636

Part #: 509292

Part #: 101-205A

Part #: 509292

Part #: 862-493

Part #: 227-027

Part #: 862-480

Part #: 335-010A

Part #: 449-621

Part #: 862-438

Part #: 862-402

Part #: 449-107

Part #: 449-135

Part #: 451-220

Part #: 449-609A

Part #: 862-496

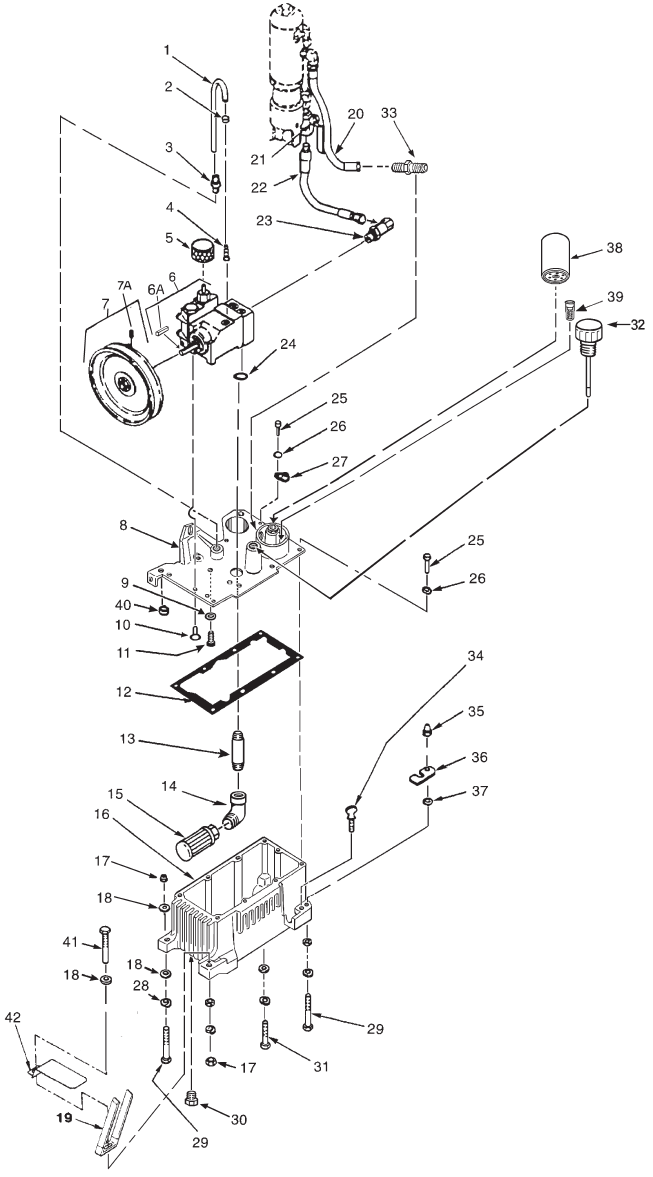

Keep your PowrTwin 4500 spraying system performing at its best by focusing on the hydraulic system, one of the most critical subsystems for drive and fluid delivery. Our selection of genuine hydraulic system parts ensures correct function, reliable pressure control and long‑term durability.

Explore some of the key items listed under this category

Pro Tip: If you experience reduced drive performance, the pump not reaching full pressure, or unusual leaks from hydraulic lines/fittings, inspect these hydraulic system parts first. A worn or mismatched connector, fitting or pressure control knob often leads to system inefficiency.

Here are the steps to guide your selection of the correct hydraulic system component:

This category covers parts such as hydraulic tube connectors (# 431‑042), elbow fittings (# 192‑228), pressure control knobs (# 448‑243), square keys (# 448‑492), and other fittings and hardware that make up the hydraulic drive circuit.

If the issue is related to the hydraulic drive (e.g., pump not reaching full speed/pressure, visible leaks from hydraulic lines, or erratic drive behaviour) rather than the fluid pump or motor directly, then hydraulic system parts are likely the cause. For instance, the manual highlights that the hydraulic fluid level and condition are critical in the hydraulic system.

Yes, they’re under pressure, subject to vibration and heat. Connectors, fittings or knobs may degrade, loosen or leak over time, especially under heavy use. Regular inspection is recommended.

While it might be possible, using genuine parts is strongly recommended. The PowrTwin 4500’s hydraulic system has specific requirements for pressure rating, thread type, and compatibility. Using incorrect fittings may lead to leaks or failure and might void the warranty.

The manufacturer’s manual recommends daily fluid level checks and hydraulic fluid changes every six months with the correct fluid (Titan/Speeflo Coolflo™). Also inspect connectors, fittings, and pressure control hardware at regular intervals or after major jobs.

Browse our full selection of PowrTwin 4500 hydraulic system parts above and choose the exact components you require. If you’re unsure which part number matches your machine or how to diagnose the right part, contact our support team — we’re here to help you identify the correct part and keep your sprayer’s hydraulic system in optimal condition.