Subcategories

NEW PRODUCTS FOR FEBRUARY - POWRCOAT 975

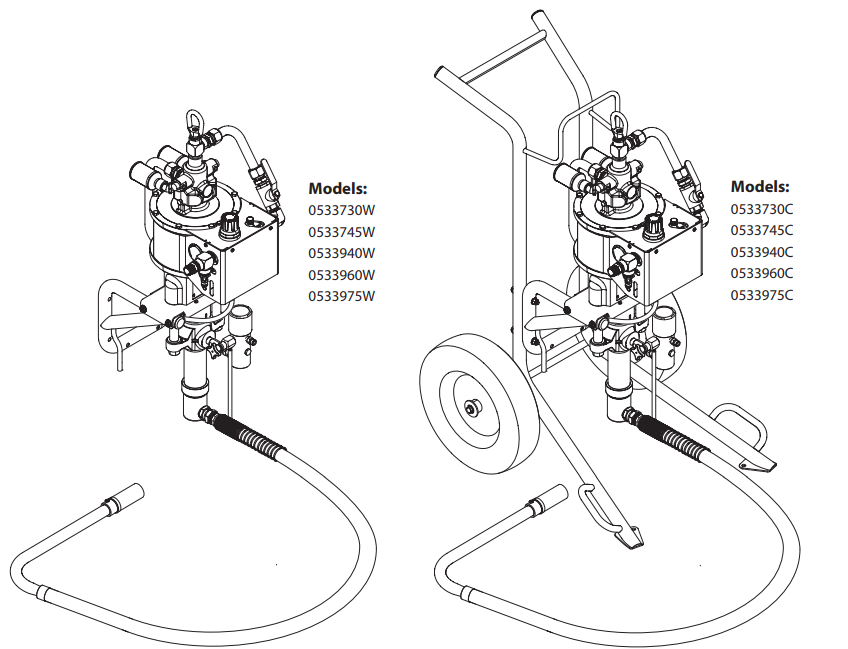

The PowrCoat 975 is an ultra-high output industrial airless coating system designed for continuous, large-scale production environments. Engineered as a wall-mount airless sprayer, the PowrCoat 975 delivers maximum material flow, stable operating pressure, and consistent spray quality for the most demanding protective and industrial coatings.

Powered by a heavy-duty air motor and the precision Fluid Pump Assembly (0533908), the PowrCoat 975 is built for fixed spray installations where performance, durability, and minimal downtime are critical. The system supports a complete range of PowrCoat 975 replacement assemblies, allowing efficient maintenance and long-term operational reliability.

Ultra-high output wall-mount industrial airless coating system

Powerful air motor for continuous, high-volume spraying

Precision PowrCoat 975 Fluid Pump Assembly (0533908) for high-viscosity materials

Automatic lubricator assembly to reduce wear and extend component life

High-pressure filtration for clean, uninterrupted material flow

Integrated bleed valve assembly for safe pressure relief

Gun manifold assemblies support multiple spray guns

Designed for long service life in demanding industrial environments

Applications

Large-scale industrial manufacturing facilities

Protective and corrosion-resistant coating operations

Structural steel and heavy fabrication plants

Marine, automotive, and heavy equipment coating lines

Centralized spray booths and fixed production systems

The PowrCoat 975 is designed for high-viscosity and heavy industrial coatings, including epoxies, elastomerics, fireproofing materials, and corrosion-resistant protective coatings.

The PowrCoat 975 uses the Fluid Pump Assembly (0533908), engineered to provide high material output, reduced pulsation, and consistent spray performance.

The automatic lubricator assembly reduces internal friction in the air motor, minimizes component wear, and helps extend the overall service life of the sprayer.

The PowrCoat 975 gun manifold assembly should be replaced if you notice persistent leaks, pressure instability, uneven spray patterns, or visible damage to the manifold body or threads. Replacing a worn or damaged manifold ensures proper fluid distribution, maintains consistent spray performance, and prevents damage to connected hoses and spray gun components.