Subcategories

NEW PRODUCTS FOR FEBRUARY - HYDRA SERIES SPRAYER PARTS

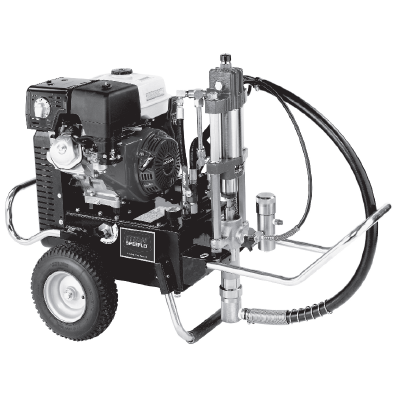

The Hydra Series Sprayer Parts collection includes essential replacement components designed for the reliable performance of SPEEFLO and Hydra airless sprayer models such as the Hydra Pro IV, Hydra M2000, Hydra M4000, and Hydra X (4540/7230). Engineered to meet the demanding needs of contractors and industrial users, these parts ensure smooth operation, consistent spray pressure, and long-term durability for both gas-powered and electric Hydra sprayer units.

Whether you’re maintaining your sprayer for peak efficiency or performing a complete rebuild, Hydra Series replacement parts offer OEM-grade precision and compatibility for maximum sprayer life and minimal downtime.

All parts are built to original equipment specifications for perfect fit, optimal performance, and reliable operation.

Made to withstand the high pressures and continuous workloads typical in professional spraying environments.

Covers a range of sprayers, including Pro IV Gas Sprayers, M2000, M4000, and Hydra X units.

Maintaining worn parts helps restore spray consistency, reduce pulsation, improve transfer efficiency, and extend equipment life.

Most parts are quick to replace on-site, reducing downtime and ensuring your sprayer stays job-ready.

Hydra Series Sprayer parts support maintenance and repair for sprayers used in:

These replacement parts help maintain consistent performance across a wide variety of coatings including latex, acrylics, elastomers, stains, primers, and specialty industrial finishes.

Check your sprayer model number (e.g., Hydra Pro IV, M2000, M4000, Hydra X 4540/7230). Each part listing typically includes supported models. If unsure, match the part number in your sprayer’s manual.

Typical wear parts include pump packing kits, filters, valves, hoses, spray guns, and seals. High-pressure components may require replacement more frequently under heavy use.

Routine maintenance is recommended every 50–100 hours of operation, depending on material thickness and job conditions. Pumps used with abrasive coatings may require more frequent service.

Most basic maintenance items filters, seals, hoses, and spray tips can be replaced with simple tools. Pump rebuilds may require more experience, but step-by-step manuals are available for guidance.

OEM parts are engineered to match factory specifications and typically offer better reliability, fit, and performance compared to generic aftermarket substitutes.