Subcategories

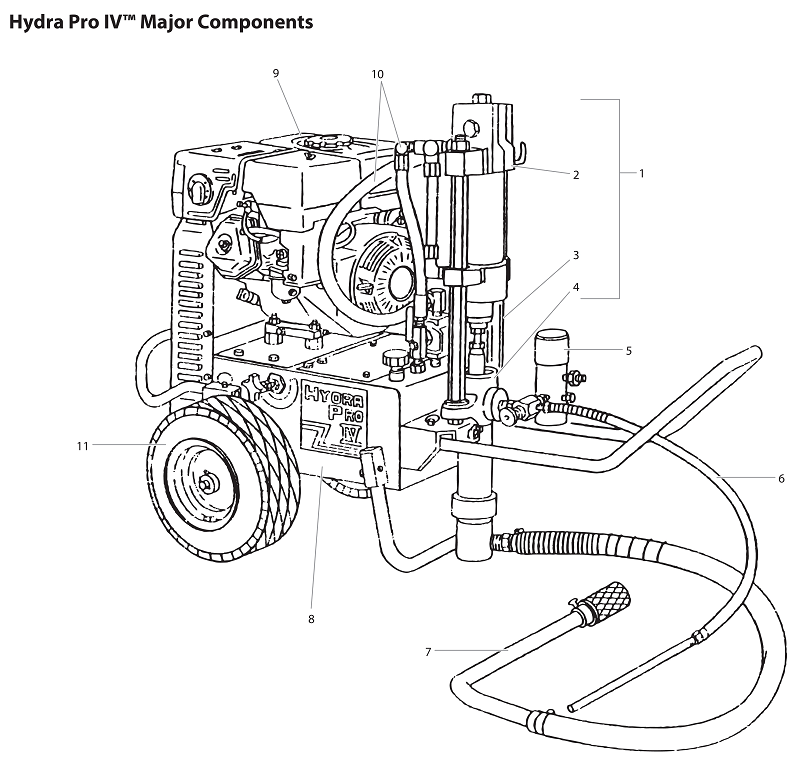

Hydra Pro IV Major Component Parts

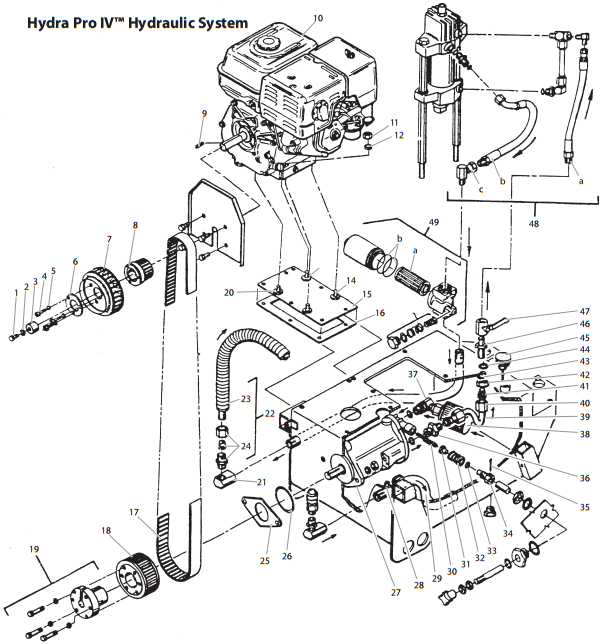

Hydra Pro IV Hydraulic System Parts

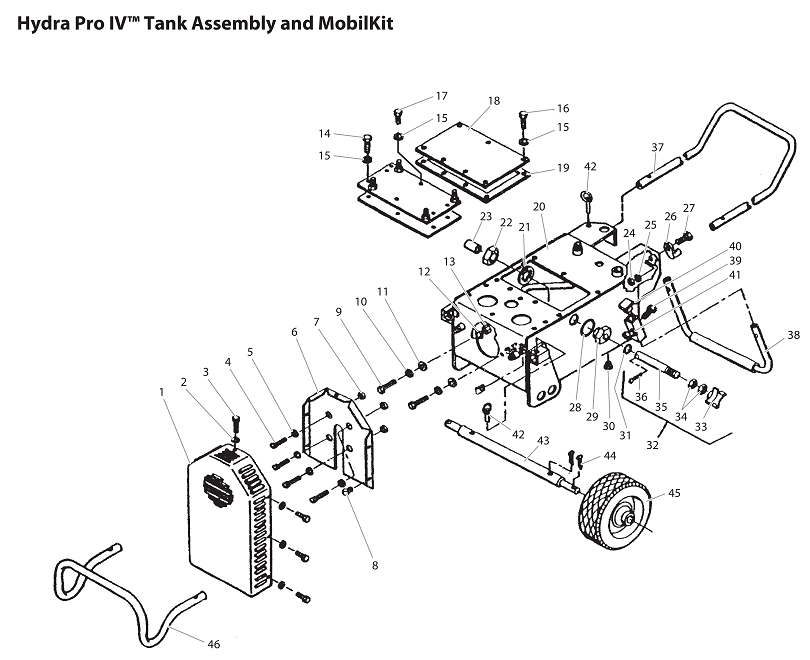

Hydra Pro IV Tank Assembly and Mobil kit Parts

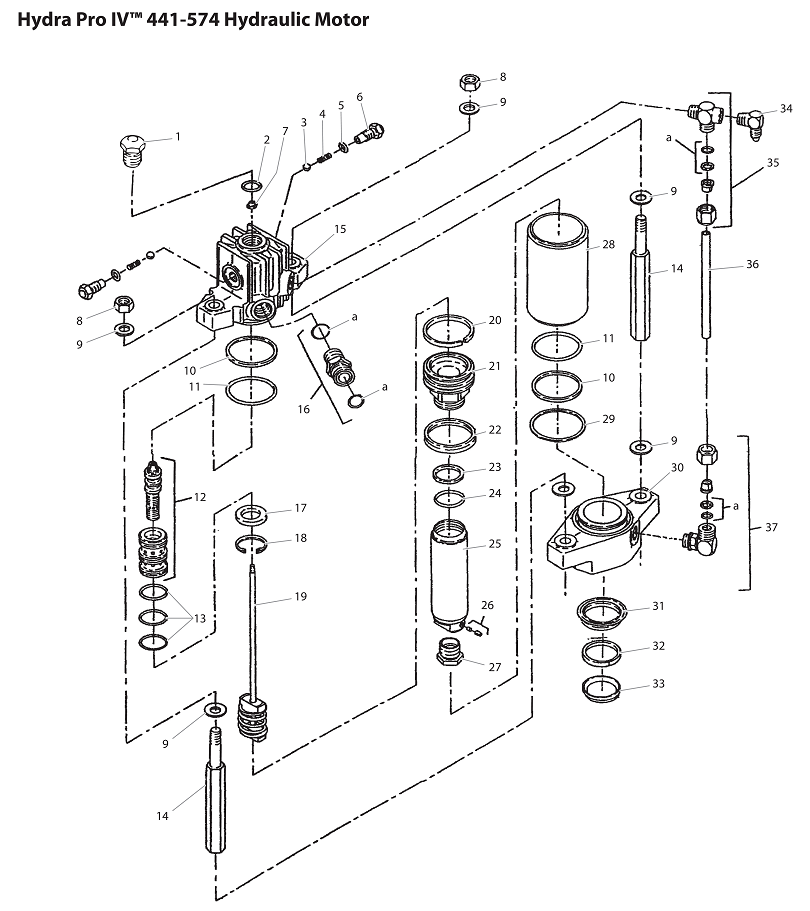

Hydra Pro IV Hydraulic Motor Parts (441-574)

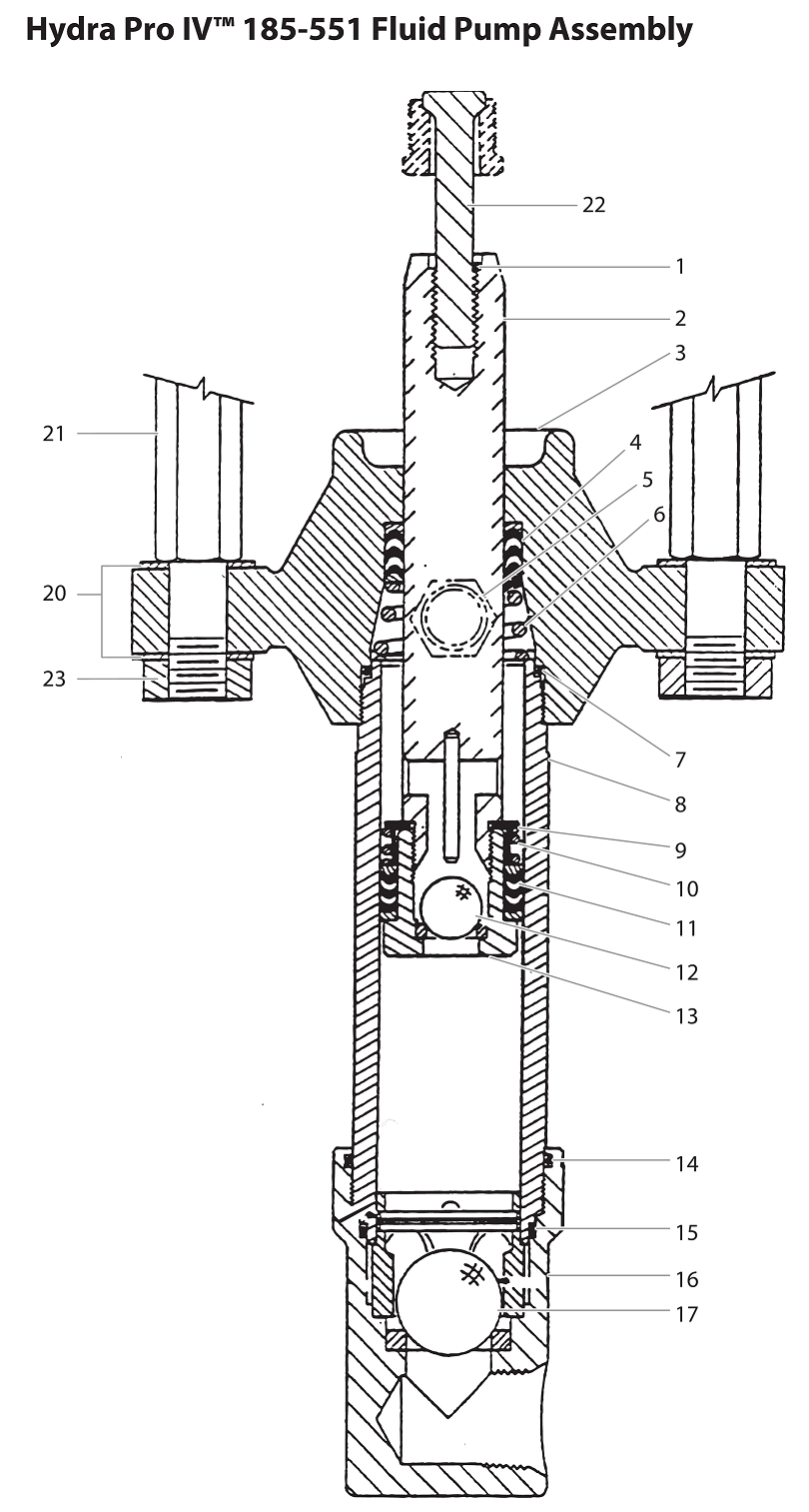

Hydra Pro IV 185-551 Fluid Pump Assembly Parts

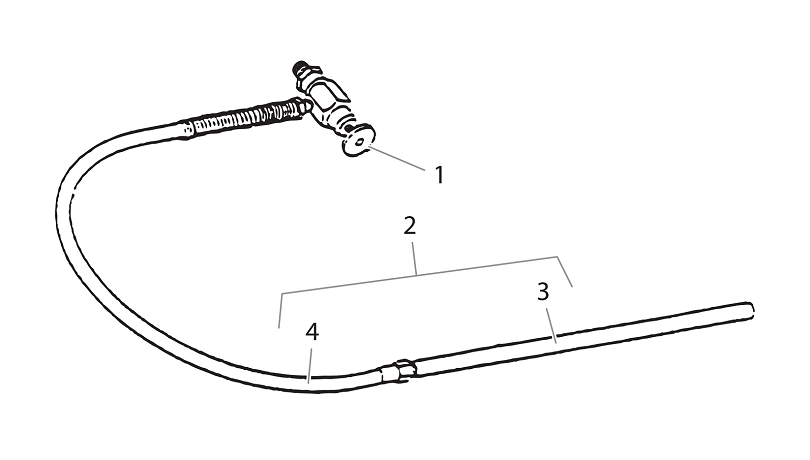

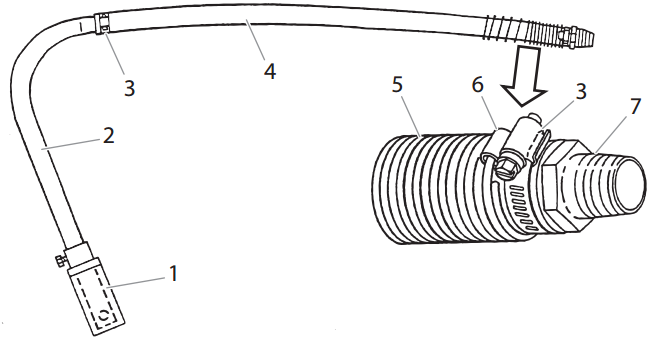

Hydra Pro IV Bleed Line Assembly With Valve Parts

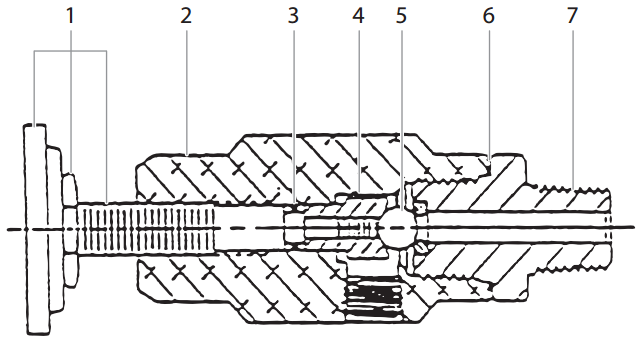

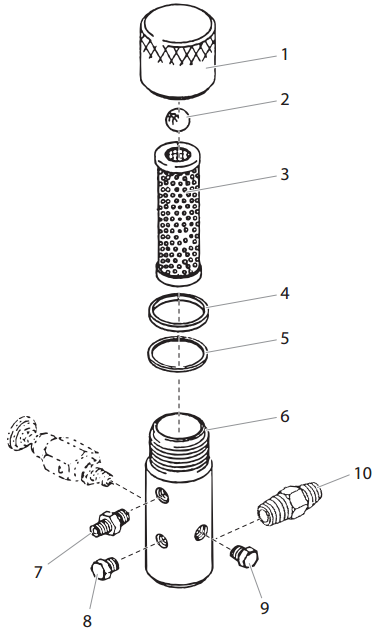

Hydra Pro IV Bleed Valve Assembly Parts

Hydra Pro IV Siphon Valve Assembly Parts

Hydra Pro IV Outlet Accessories Parts

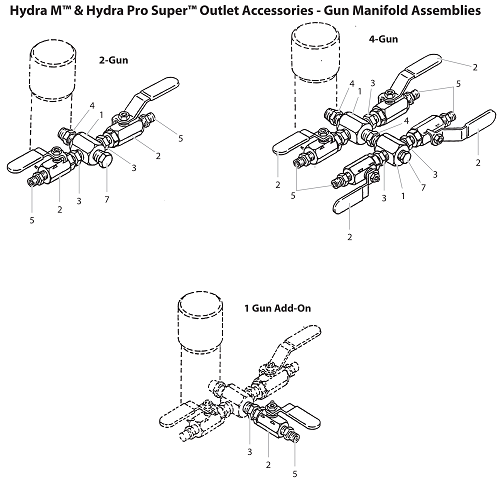

Hydra M and Hydra Pro IV Super Outlet Accessories Parts-Gun Manifold Assemblies

Hydra Pro IV Accessories Parts

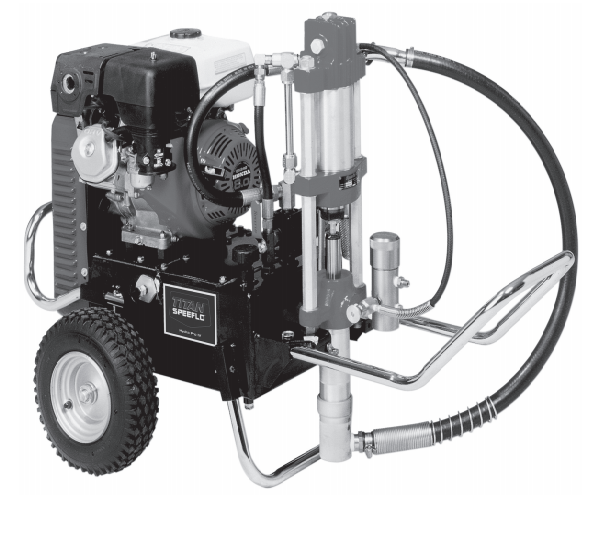

NEW PRODUCTS FOR FEBRUARY - SPEEFLO HYDRA PRO IV GAS POWERED AIRLESS SPRAYER

The SPEEFLO Hydra Pro IV Gas Powered Airless Sprayer is built for contractors who demand uncompromising power, durability, and reliability on large-scale projects. Engineered for continuous operation, this sprayer delivers exceptional performance with high-output gas power, advanced hydraulic pressure control, and rugged pump assemblies designed to handle the toughest coatings.

From residential repainting to demanding industrial jobs, the Hydra Pro IV offers smooth atomization, consistent spray patterns, and reduced downtime thanks to serviceable modular components. Its hydraulic system design ensures cool, efficient operation for longer spraying sessions, making it one of the most trusted units for professional contractors.

Provides strong, consistent power for spraying thicker coatings and handling large projects without interruptions.

Ensures smooth pressure delivery, longer pump life, and reduced heat buildup during continuous operation.

Designed for maximum durability, capable of pumping heavy elastomerics, primers, acrylics, latex paints, and commercial coatings.

Allows for fast priming, pressure release, and maintenance, improving work efficiency on the job site.

Built to prevent clogging, deliver smooth suction, and maintain consistent material flow.

Major assemblies pump, bleed valve, siphon valve, motor, and hydraulic system—are simple to disassemble and replace.

Manufactured for durability with premium materials that withstand tough job-site environments.

The SPEEFLO Hydra Pro IV is ideal for:

Large warehouses, factories, storage tanks, and metal structures.

Interior and exterior walls, siding, and large surfaces require high productivity.

Elastomerics, waterproofing coatings, protective barriers, block-fillers, primers, and other heavy materials.

Perfect for contractors who need continuous spraying with minimal downtime.

Bridges, highway structures, public buildings, and government facilities.

Pressure loss is commonly caused by worn motor pump packings, a damaged siphon valve, or air leaks in the suction hose. Inspect packings, tighten fittings, and check the inlet screen for blockages. Replace worn components immediately to restore pressure.

Pump life varies based on material type and usage, but most contractors replace or rebuild it every 6–12 months. If you notice pulsation, reduced output, or frequent priming issues, it’s time to service or replace the fluid pump assembly.

Start with the siphon valve assembly, inlet strainer, and suction hose. Dried paint or debris can restrict flow. Clean the screen, inspect the hose for air leaks, and ensure the siphon valve is sealing properly.

If the unit won’t release pressure, continuously leaks, or struggles to prime, the bleed valve stem or seals may be worn. Replacing the bleed valve assembly typically resolves the issue quickly.

Hydraulic systems naturally warm up during operation, but excessive heat may indicate low hydraulic fluid, clogged cooling fins, or pump strain. Check hydraulic fluid levels and clean the cooling system. If heat persists, a service inspection is recommended.