Subcategories

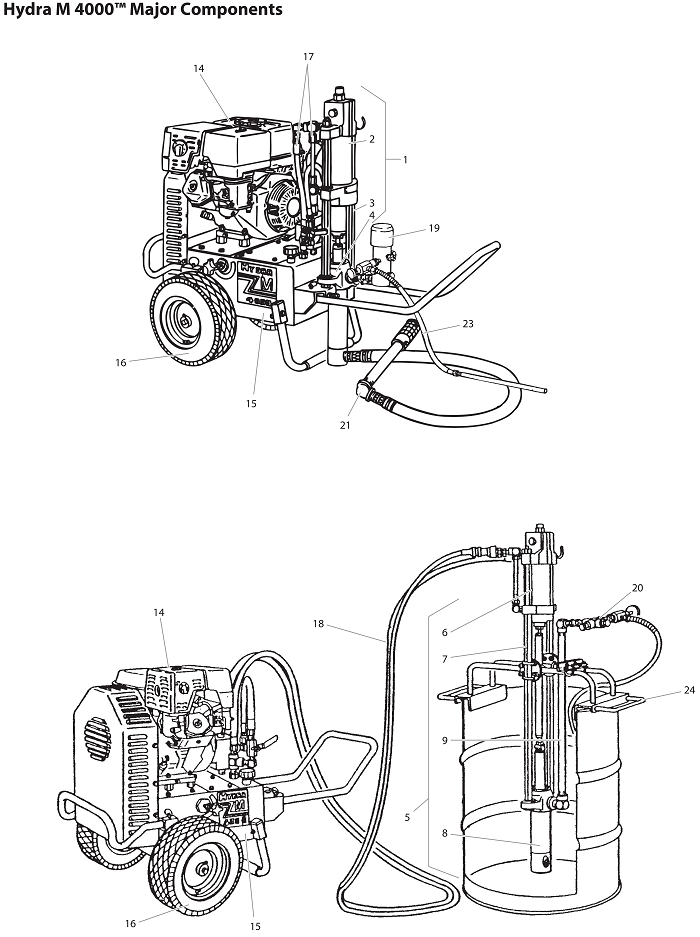

Hydra M4000 Major Components Parts

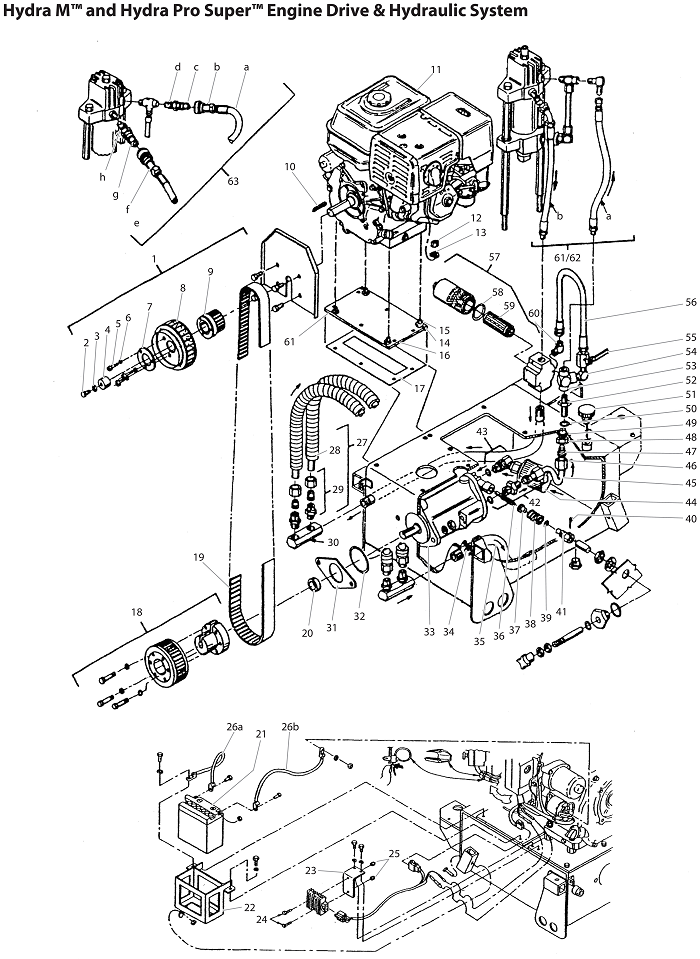

Hydra M and Hydra Pro Super Engine Drive and Hydraulic System Parts

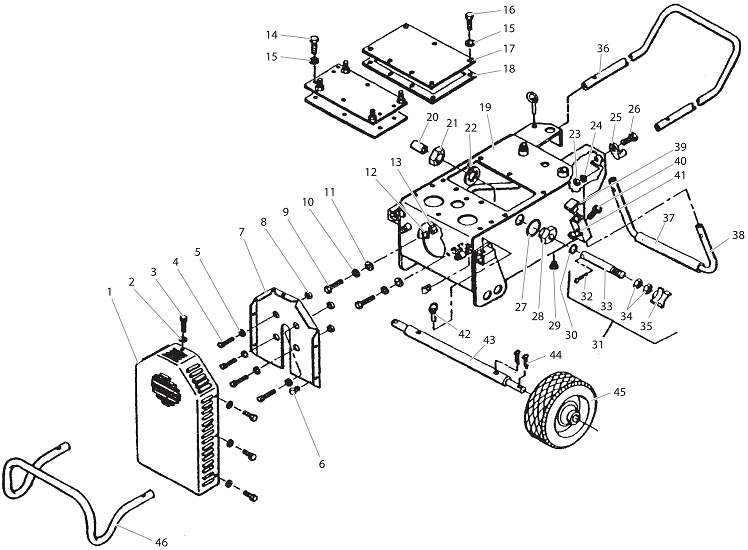

Hydra M and Hydra Pro Super Tank Assembly and Mobil Kit Parts

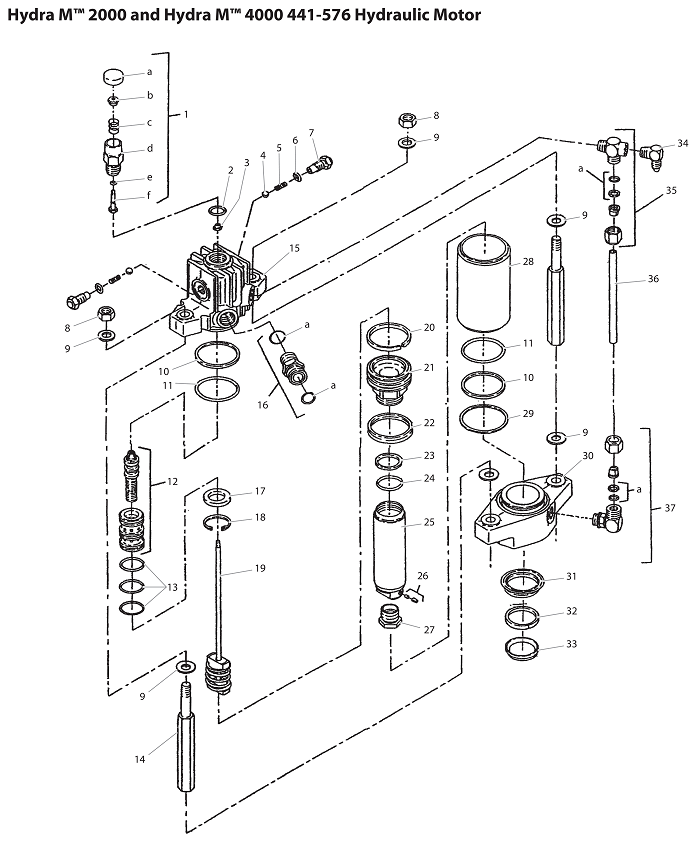

Hydra M2000 and Hydra M4000 441-576 Hydraulic Motor Parts

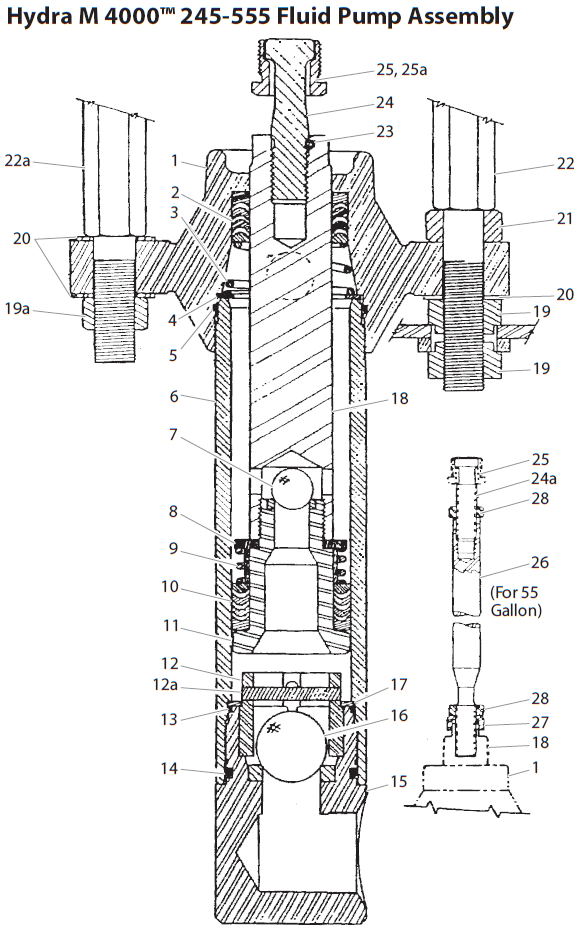

Hydra M4000 245-555 Fluid Pump Assembly Parts

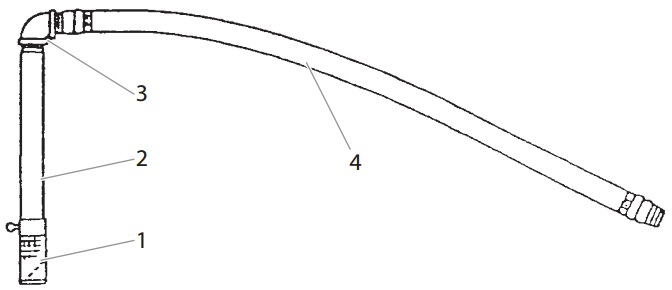

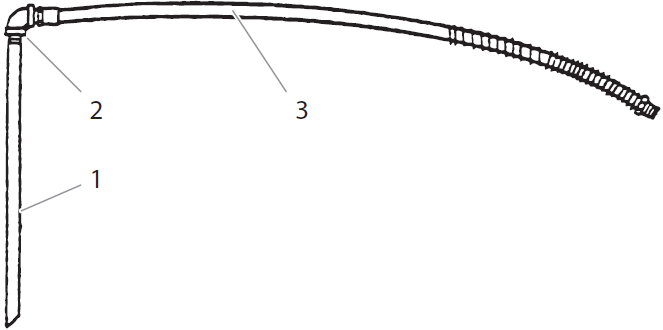

Hydra M4000 Siphon Hose Assembly Parts

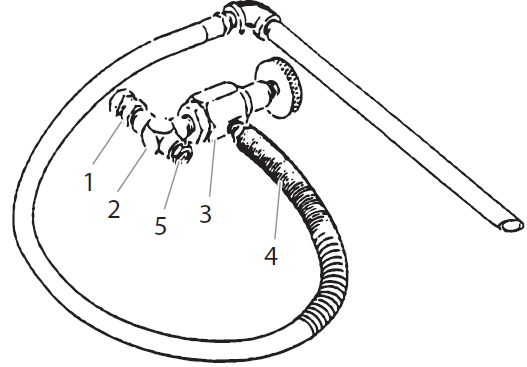

Hydra M4000 Outlet Assemblies With Pressure Bleed Valve Parts

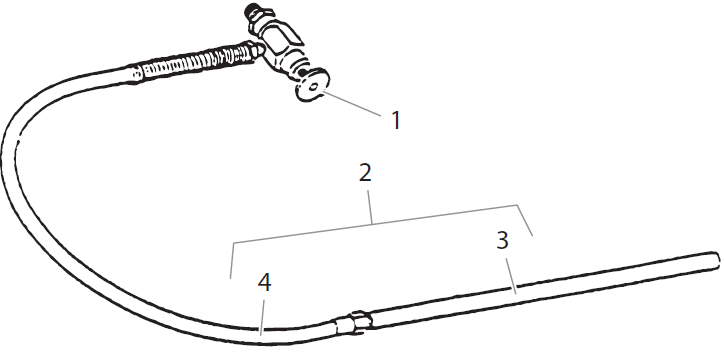

Hydra M4000 Bleed Line Assembly Parts

Hydra M4000 Bleed Line Assembly With Valve Parts

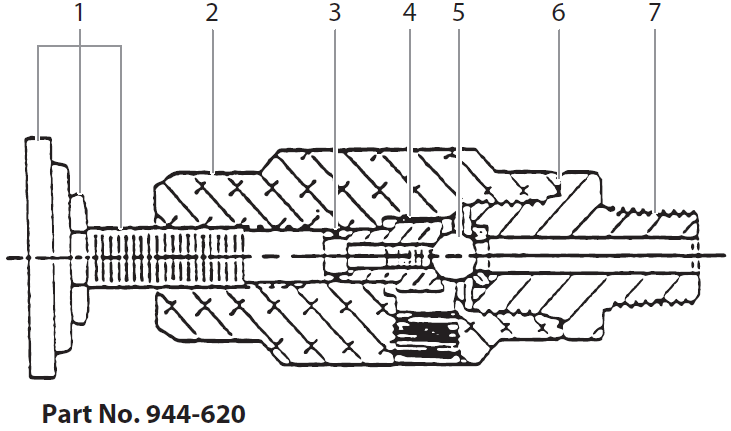

Hydra M4000 944-620 Bleed Valve Assembly, 1/8” NPT Parts

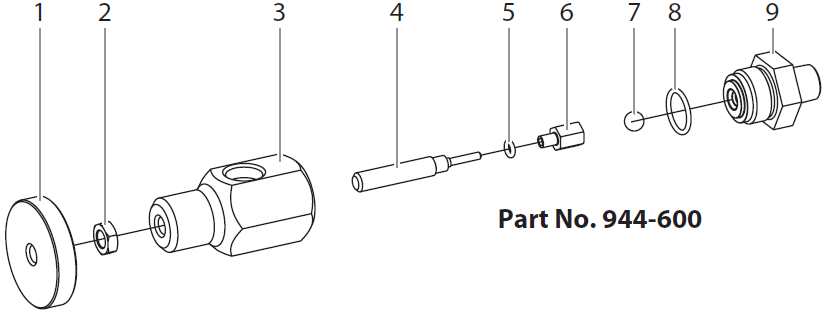

Hydra M4000 945-600 Bleed Valve Assembly, 1/2” NPT Parts

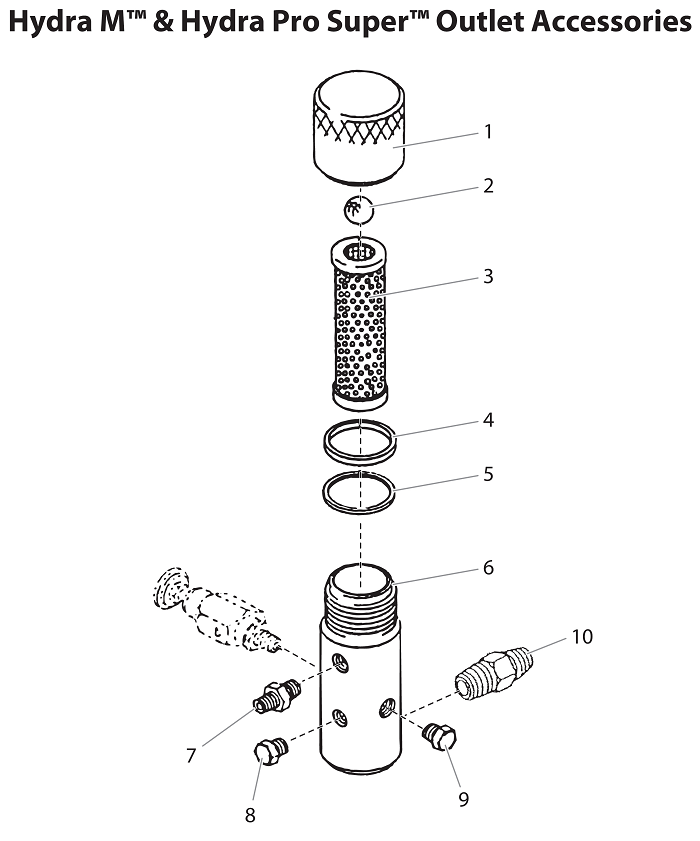

Hydra M and Hydra Pro Super Outlet Accessories Parts

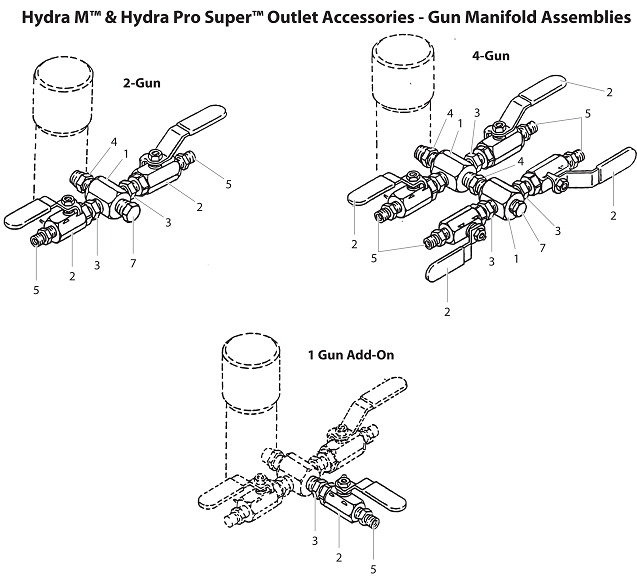

Hydra M and Hydra Pro Super Outlet Accessories Gun Manifold Assemblies Parts

Hydra M4000 Accessories Parts

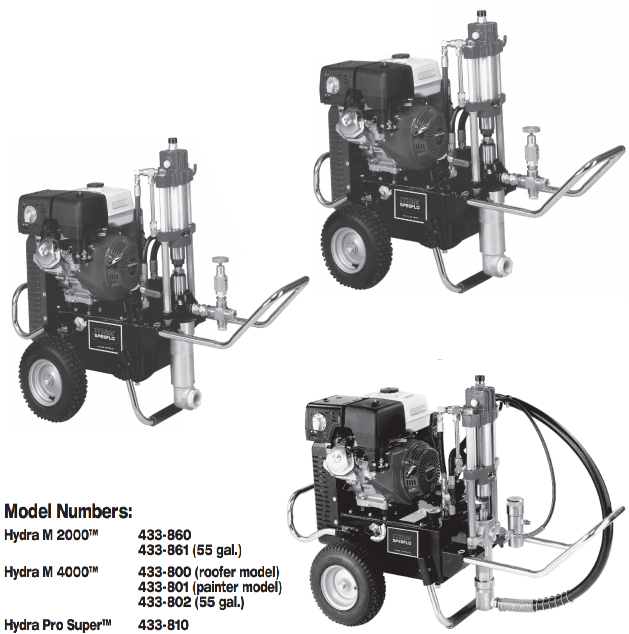

NEW PRODUCTS FOR FEBRUARY - HYDRA M4000

The Hydra M 4000 is a top-tier hydraulic airless sprayer built for heavy-duty, high-volume, industrial, and commercial coating work. As part of the “Hydra” line, it uses a powerful gas engine and a robust hydraulic piston-pump system engineered to crush through the toughest, most viscous coatings, mastics, epoxies, elastomerics, roof coatings, waterproofing compounds, and other heavy coatings that standard sprayers can’t handle efficiently.

Thanks to its ultra-slow-stroking hydraulic drive, severe-service pump components, and high maximum pressure, the Hydra M 4000 delivers consistent flow and atomization even under continuous heavy-duty operation. Whether used with a siphon hose, remote drum feed, or multiple-gun setup, it’s designed for reliability, longevity, and maximum productivity, a true “workhorse” for contractors, roofers, and industrial painters.

The Hydra M 4000 is best suited for:

If you notice reduced flow, loss of pressure, pulsation, or difficulty priming, these are typical signs that the pistons, seals, or packing are worn. Because Hydra units are used for heavy coatings, wear of internal components over time is expected. Regular inspection of pistons, cylinders, packing, valves, and suction components is important. If cleaning and servicing don’t restore proper performance, rebuild or replacement is likely necessary.

Overheating often stems from extreme load, e.g., overly viscous coatings, long continuous use without rest, or insufficient cooling airflow. To minimize stress: use recommended coatings (or thin heavy coatings as per manufacturer instructions), allow cooldown periods during long jobs, maintain clean hydraulic fluid (if serviceable), and avoid overworking the motor pump beyond intended duty cycles. Also, ensure adequate ventilation around the unit.

Yes, the Hydra M 4000 supports multiple guns. The specification shows tip sizes for up to 5 guns (with progressively smaller tip sizes per gun).

The outlet manifold filter assembly typically includes a filter cap assembly, a stainless ball check, a 50-mesh screen filter, PTFE gaskets (thick and thin), a filter body rated for up to 5000 psi, a hex nipple, pipe plugs, and a swivel fitting for hose/gun connections

Cleaning the filter regularly is important because a dirty or clogged filter can reduce filtering effectiveness, causing poor spray patterns, clogged spray tips, or other performance issues. You should relieve system pressure first, then remove the filter cap, pull out the filter element (with check ball), clean the filter body and screen thoroughly with a suitable solvent, and inspect for damage before reinstalling.