Subcategories

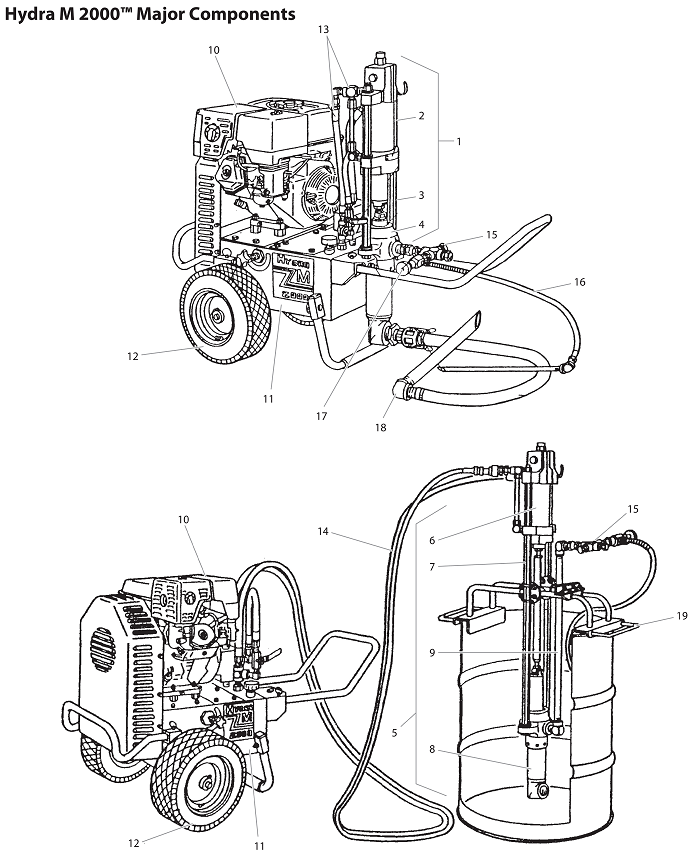

Hydra M2000 Major Components

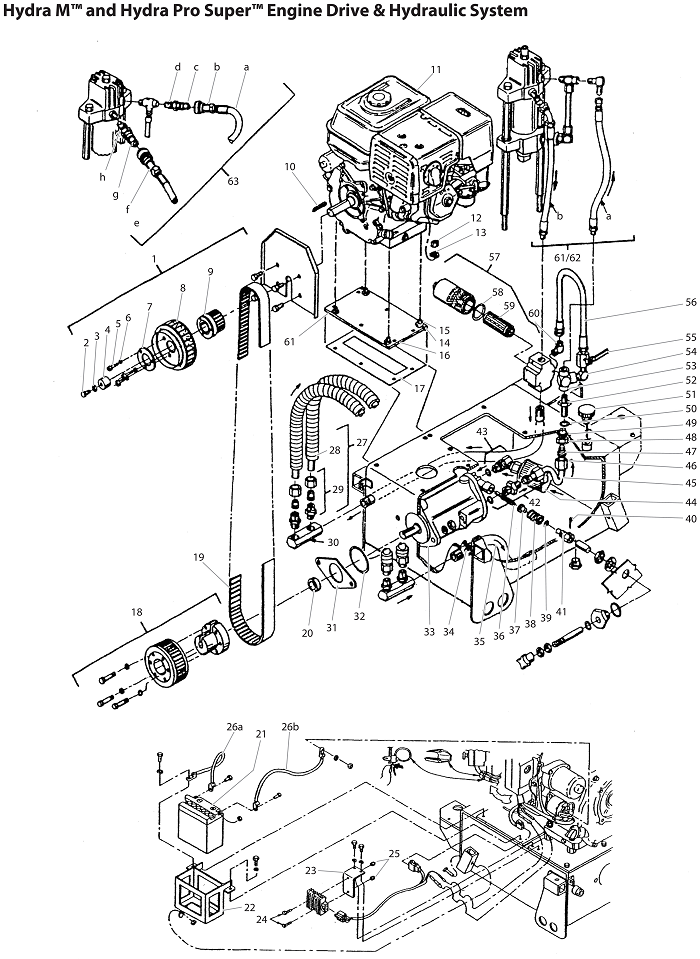

Hydra M and Hydra Pro Super Engine Drive & Hydraulic System

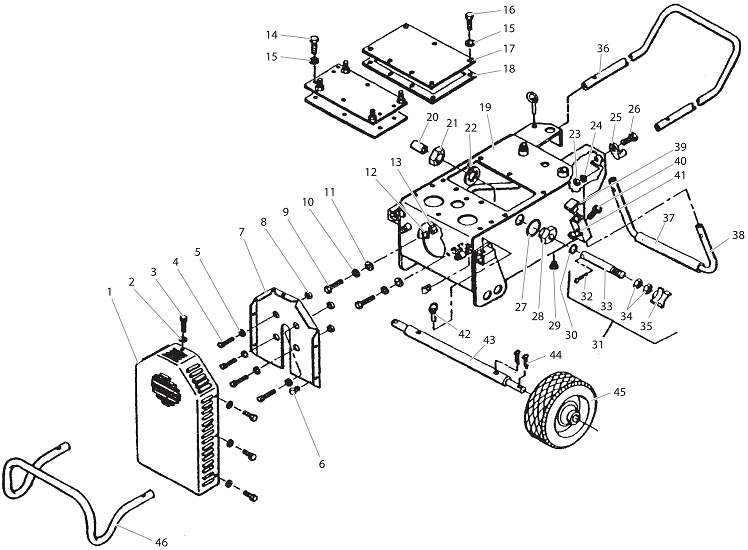

Hydra M and Hydra Pro Super Tank Assembly and Mobil Kit

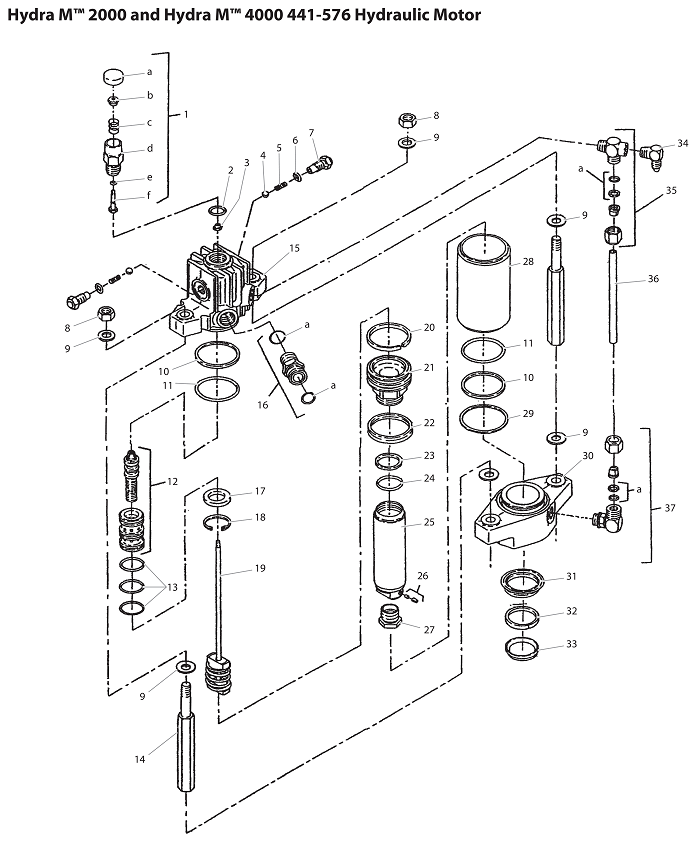

Hydra M2000 and Hydra M4000 441-576 Hydraulic Motor

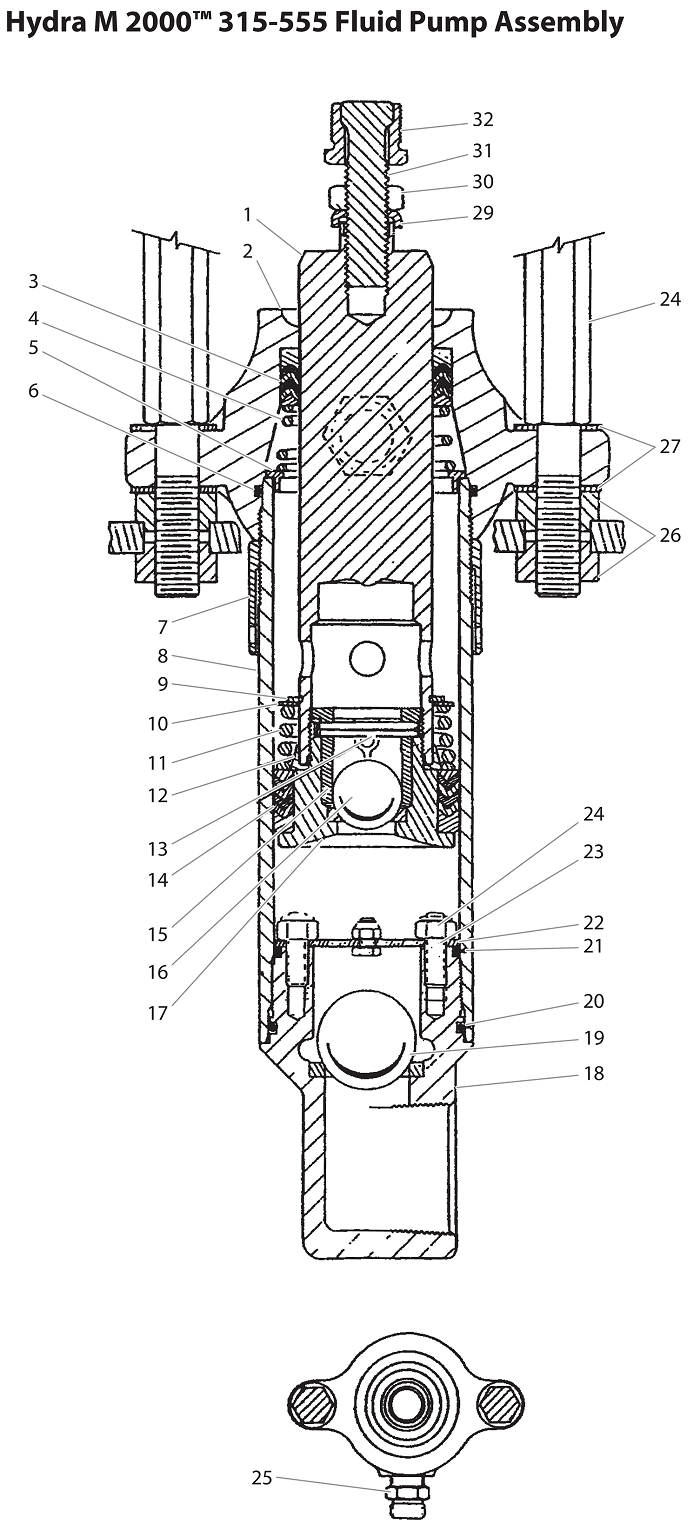

Hydra M2000 315-555 Fluid Pump Assembly

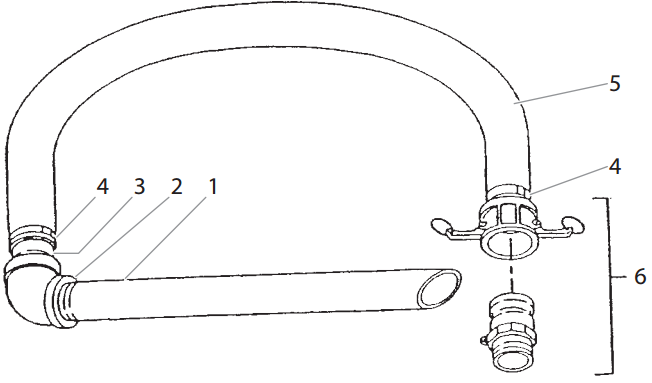

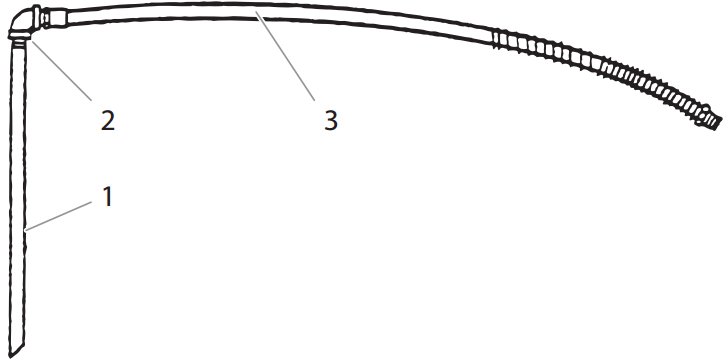

Hydra M2000 Siphon Hose Assembly

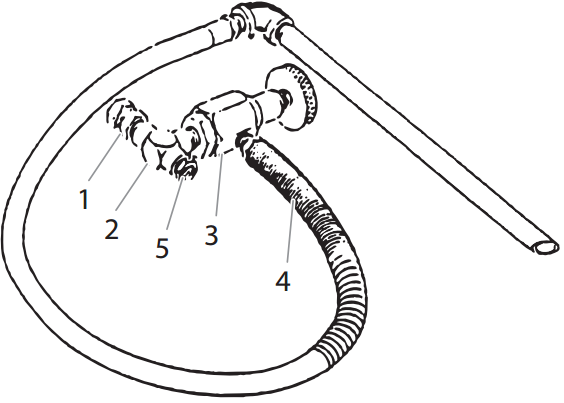

Hydra M2000 Outlet Assemblies With Pressure Bleed Valve

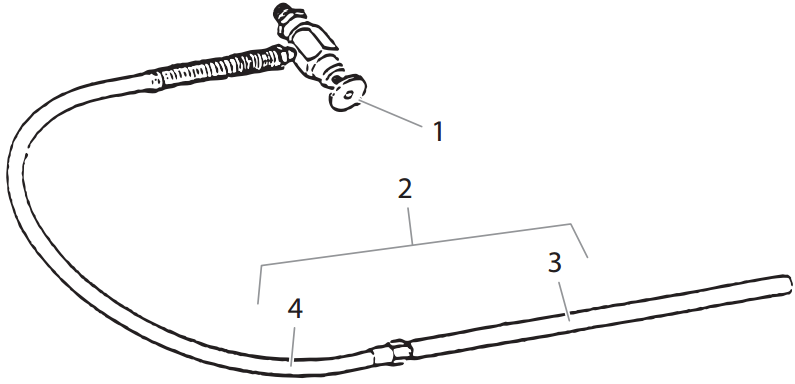

Hydra M2000 Bleed Line Assembly

Hydra M2000 Bleed Line Assembly With Valve

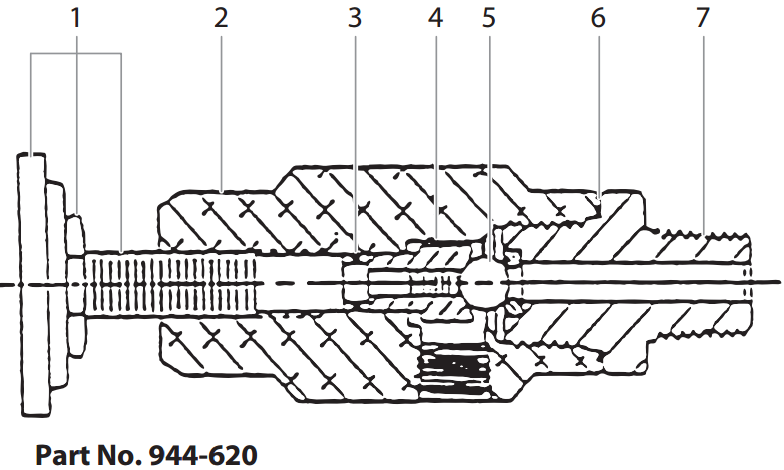

Hydra M2000 944-620 Bleed Valve Assembly, 1/8” NPT

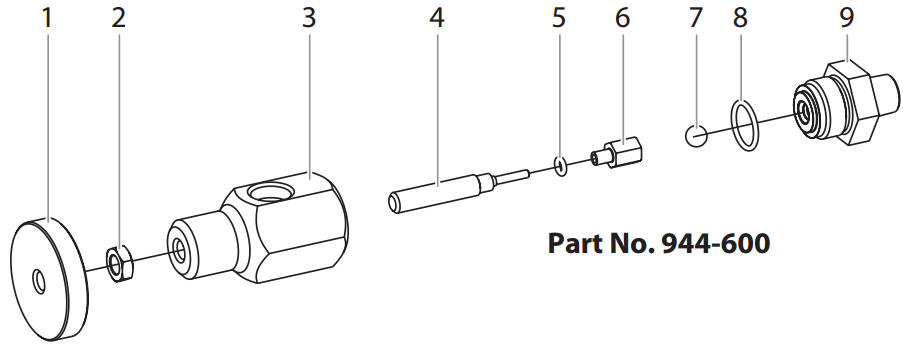

Hydra M2000 945-600 Bleed Valve Assembly, 1/2” NPT

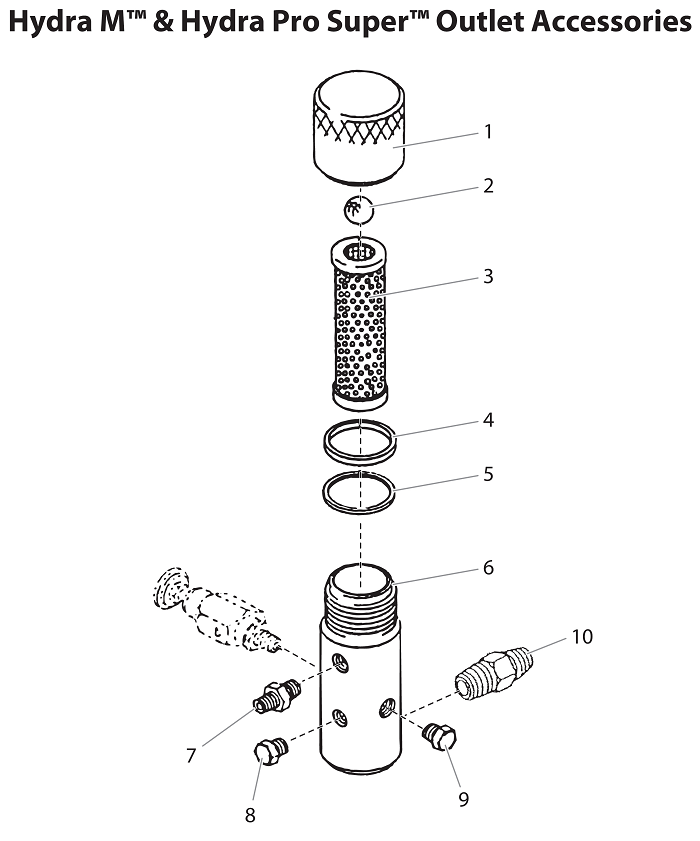

Hydra M and Hydra Pro Super Outlet Accessories

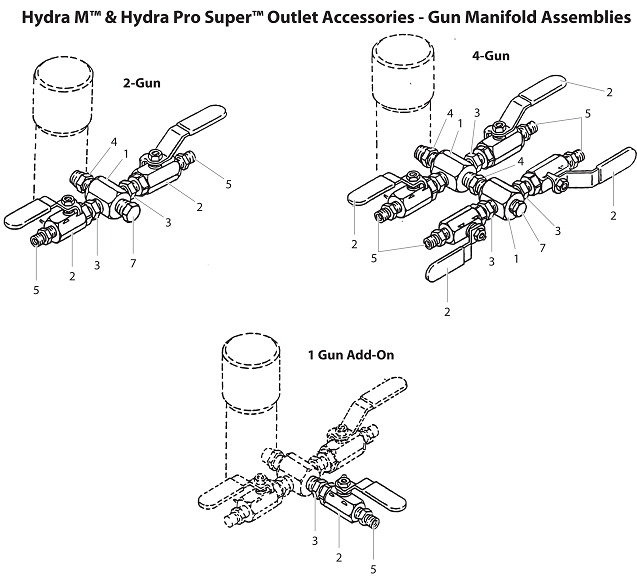

Hydra M and Hydra Pro Super Outlet Accessories - Gun Manifold Assemblies

Accessories

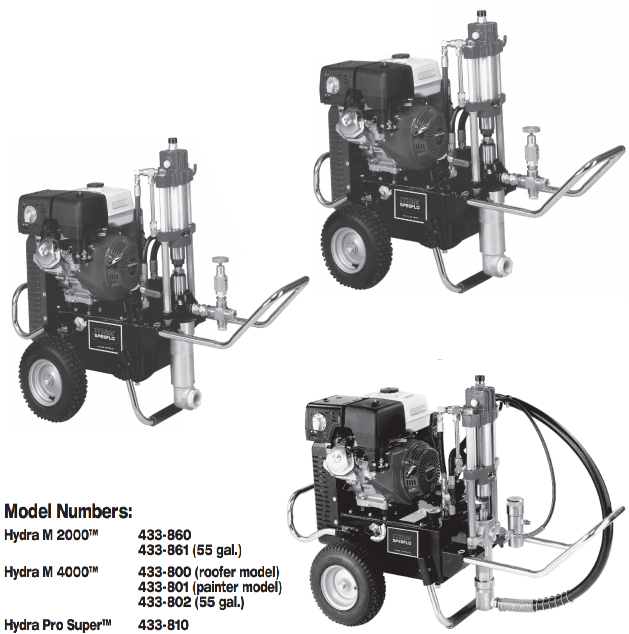

NEW PRODUCTS FOR FEBRUARY - HYDRA M2000

The Hydra M2000 is a heavy-duty hydraulic airless sprayer engineered to tackle the most demanding coating jobs across commercial, industrial, and roofing applications. As part of Titan’s renowned Hydra series, the M2000 stands out as a high-production, high-capacity sprayer built to handle ultra-heavy coatings, waterproofing compounds, mastics, roof coatings, and large-scale projects with long hose runs or multiple guns.

With a powerful gas engine driving an ultra-capacious hydraulic system, the Hydra M2000 ensures smooth, consistent pressure, long service life, and reliable performance under continuous operation. Its fluid section is designed for durability, using heavy-duty pistons and rugged components to resist wear from harsh coatings.

For contractors and professionals tackling large surfaces or tough materials, this sprayer delivers the capacity, consistency, and dependability needed for industrial-scale jobs.

The Hydra M2000 excels in use cases such as:

If you notice reduced flow, inconsistent pressure, increased pulsation, difficulty priming, or poor spray performance, these are common signs that the fluid pump section (pistons, seals, packing) is worn.

Because the Hydra M2000 is designed for heavy coatings, wear on packing or piston seals is expected after significant use. Regular inspection and maintenance (cleaning, lubrication, seal replacement) is recommended, and if performance doesn’t recover, a pump rebuild or replacement may be necessary.

Overheating or sluggish hydraulic drive could indicate low hydraulic fluid level, degraded fluid, or internal wear in hydraulic motor components (e.g., O-rings, spool valves). Also, inspect hoses and fittings for leaks or damage. Using genuine replacement hydraulic motor parts is essential to maintain proper function and longevity.

Yes, the Hydra M2000’s high output (6.0 GPM) and powerful hydraulic drive make it suitable for multi-gun setups and long hose runs, especially with heavy coatings. However, for maximum performance, ensure hoses, fittings, and spray tips are rated appropriately, and monitor pressure at the gun. Heavy coatings can cause a pressure drop over excessive hose length.

After every use: flush the system thoroughly with appropriate solvent or cleaning agent (per coating manufacturer’s recommendation). Frequently inspect and clean the inlet strainer, siphon hose assembly, and foot valve to avoid clogs or suction issues.

Periodically check and repack pistons and packing (UHMWPE), inspect O-rings and seals, and replace as needed. Use only manufacturer-specified parts and accessories (hoses, tips, valves) rated for required pressures to avoid premature wear or failure.

Always purchase from reputable distributors or trusted suppliers. Check that part numbers, logos, and packaging match manufacturer originals. Compare part diagrams from the official manual or parts list to those offered by the vendor. If in doubt, consult the parts “major component” list for Hydra M2000, including motor/pump assemblies, fluid pump (315-555), siphon hose, bleed valve assemblies, hydraulic components, etc.