Subcategories

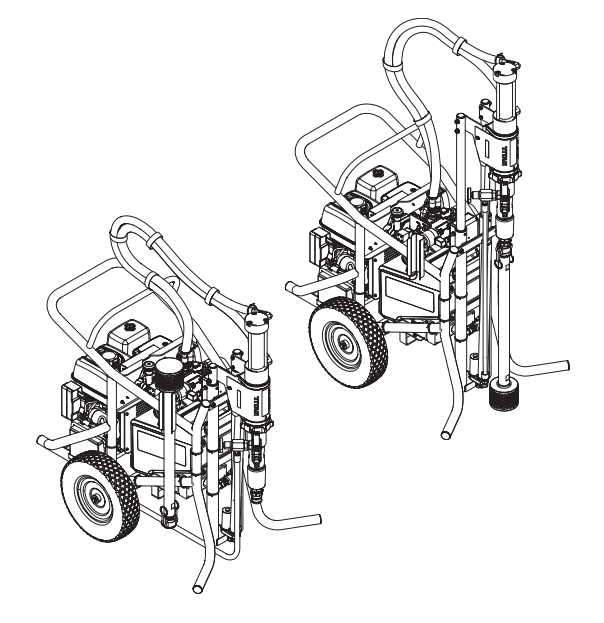

Hydra X (4540,7230) Main Assembly I

Hydra X (4540,7230) Main Assembly II

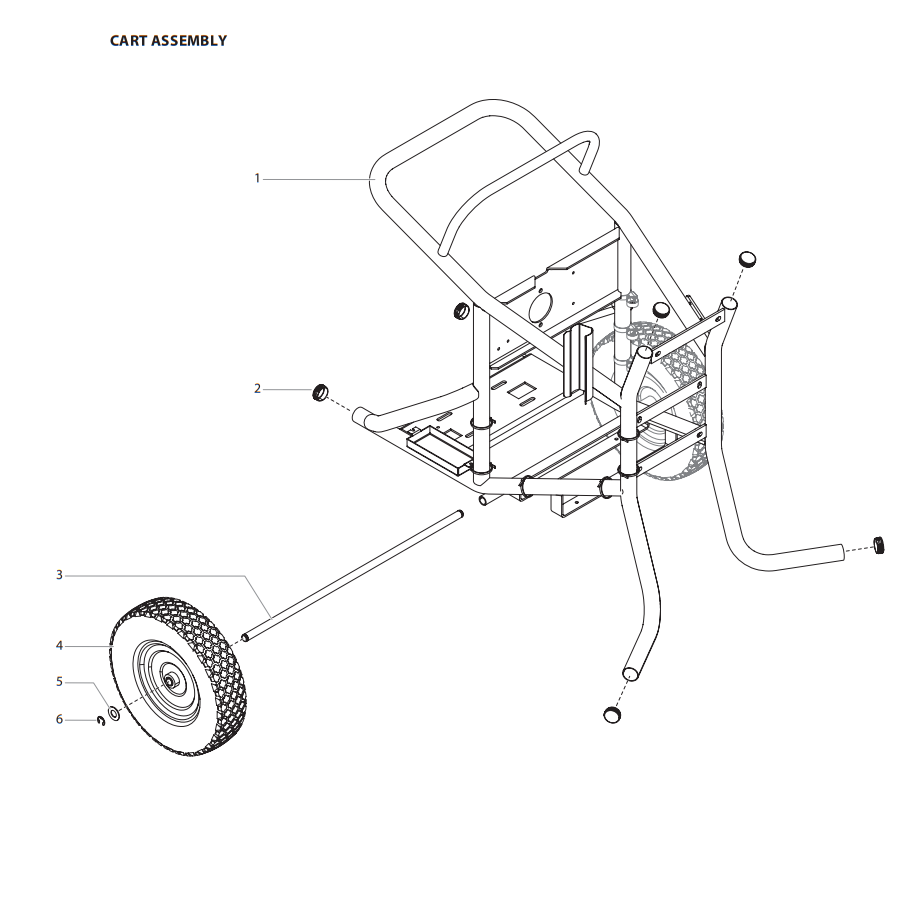

Hydra X (4540,7230) Cart Assembly

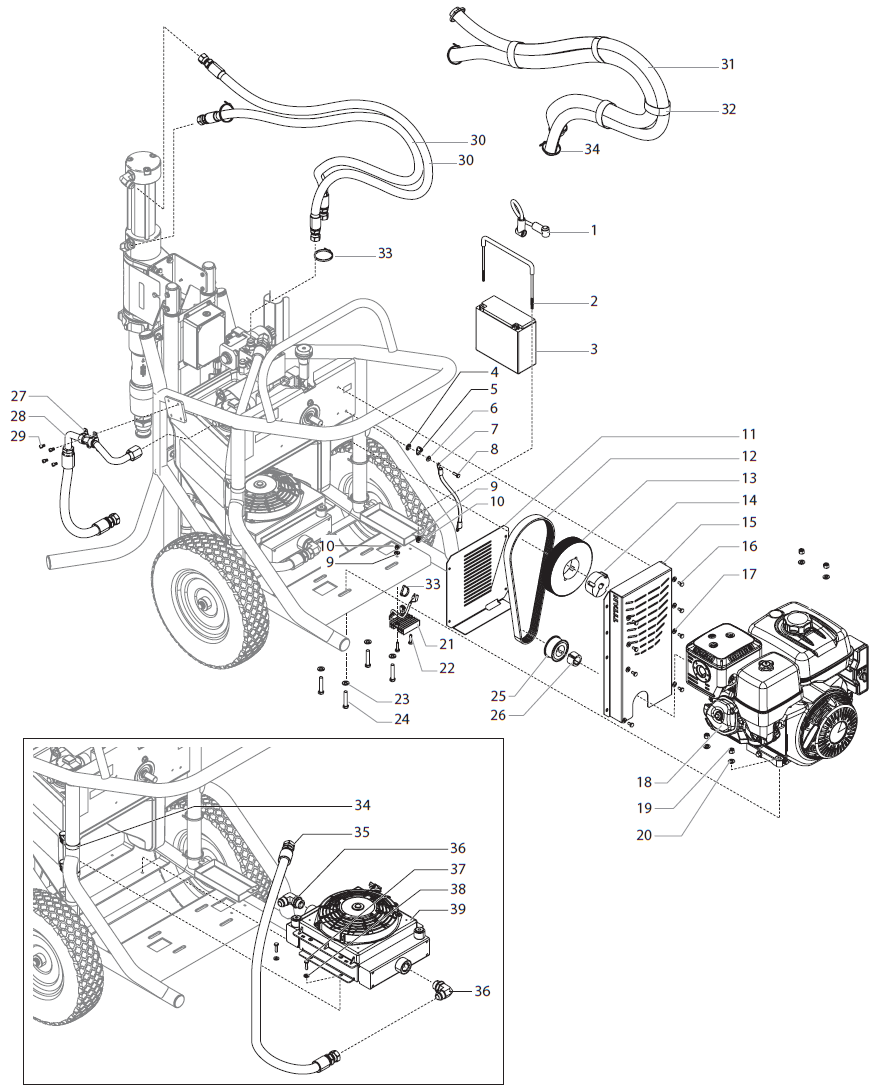

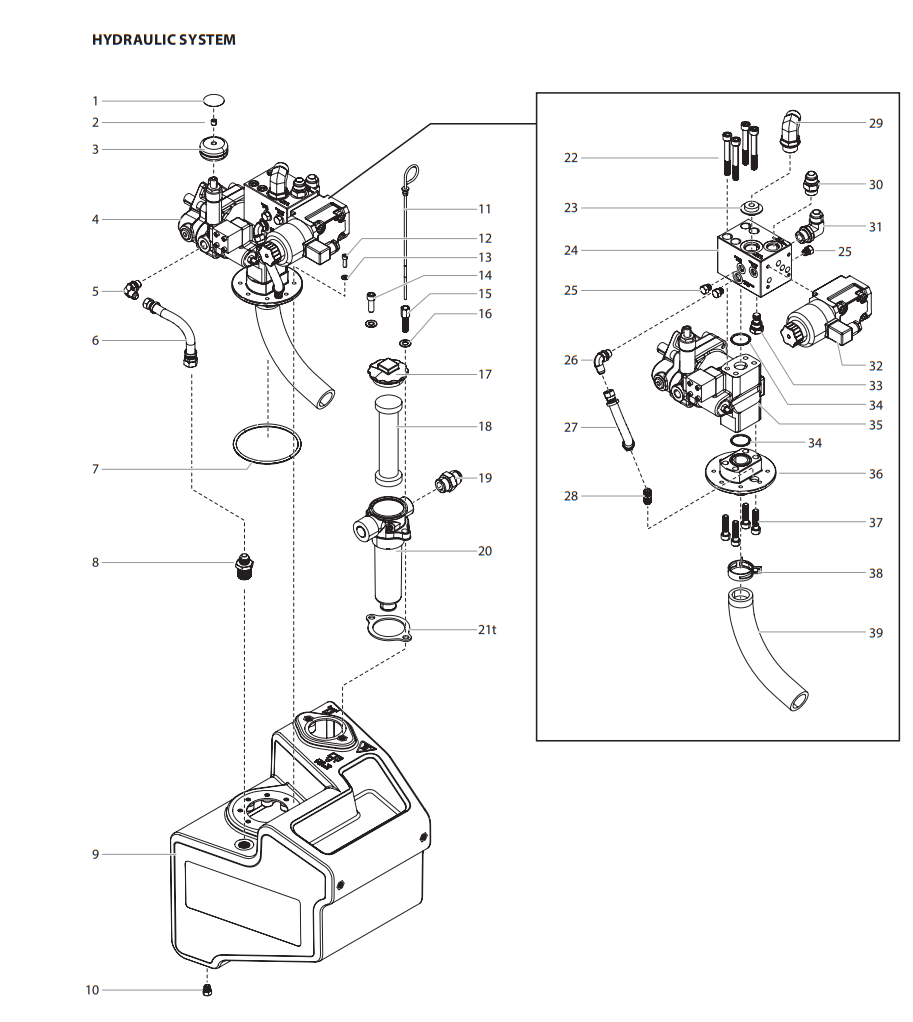

Hydra X (4540,7230) Hydraulic System

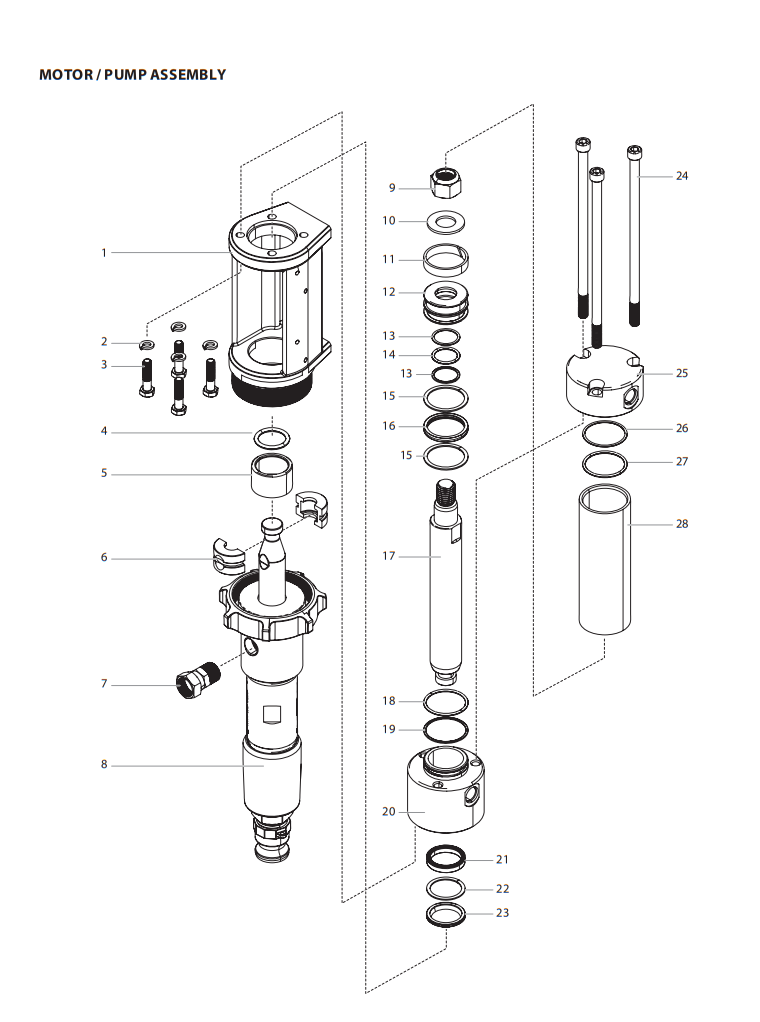

Hydra X (4540,7230) Motor / Pump Assembly

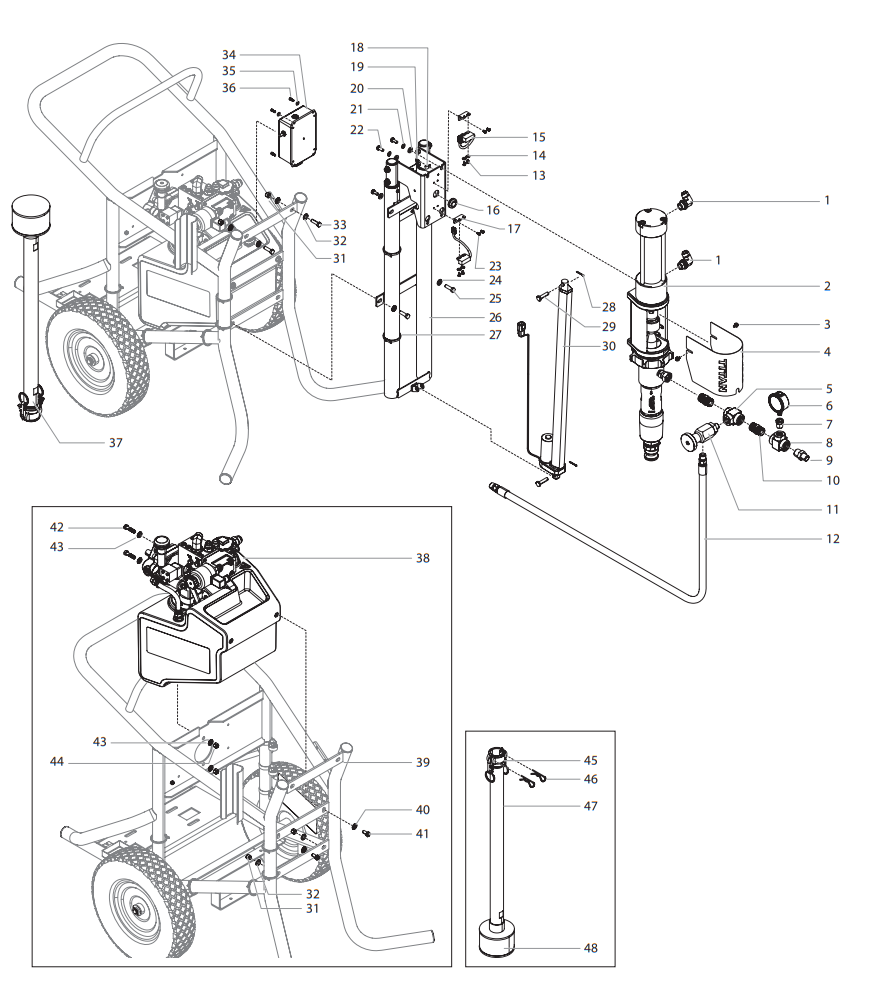

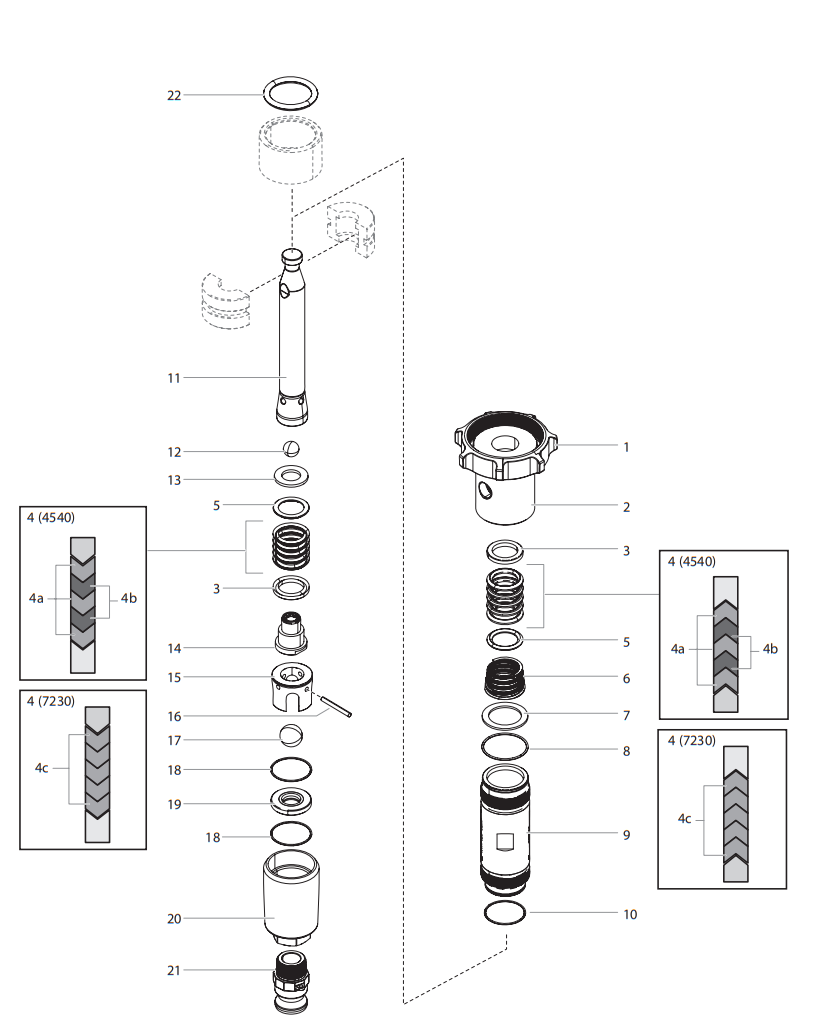

Hydra X (4540) Fluid Section

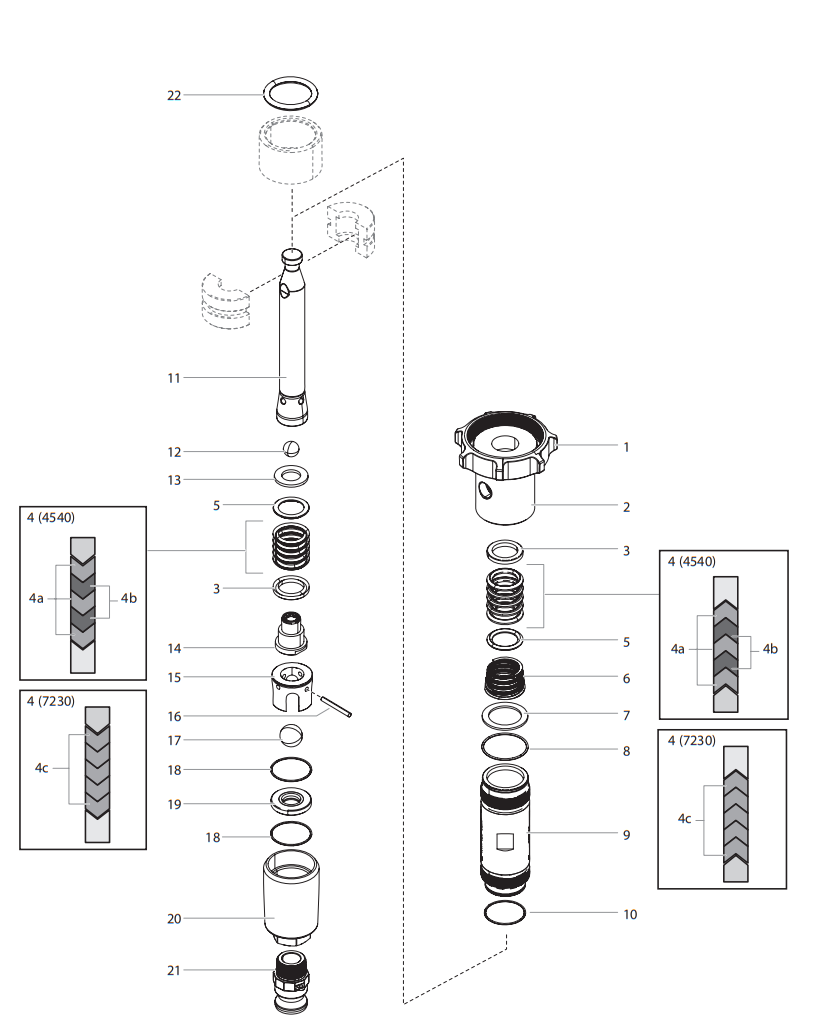

Hydra X (7230) Fluid Section

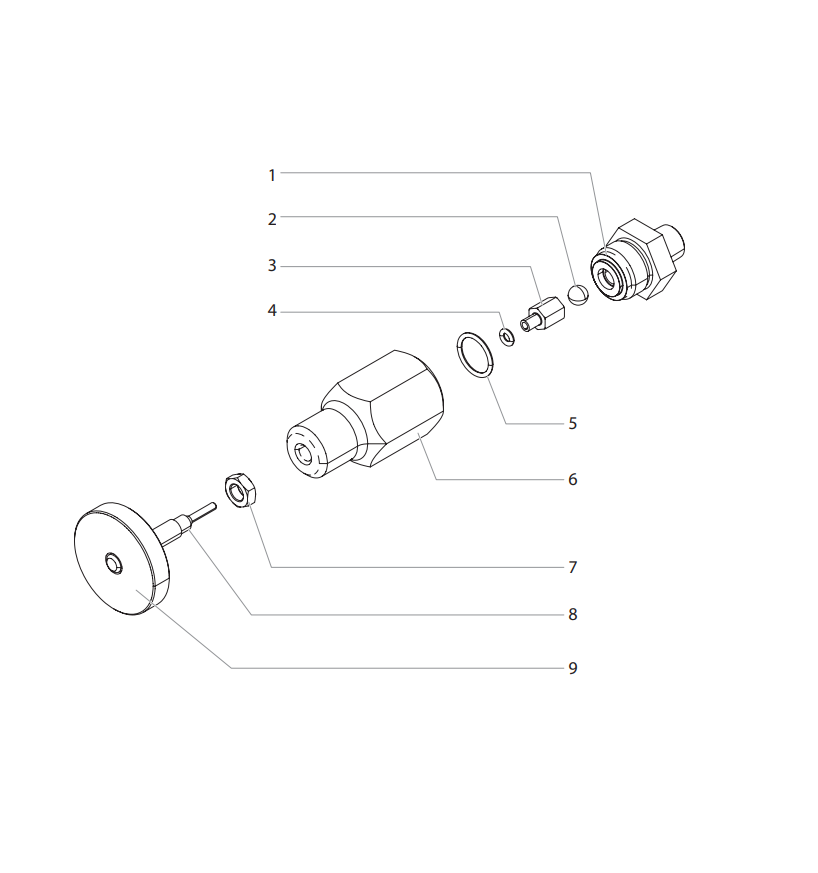

Hydra X (4540,7230) Bleed Valve Assembly

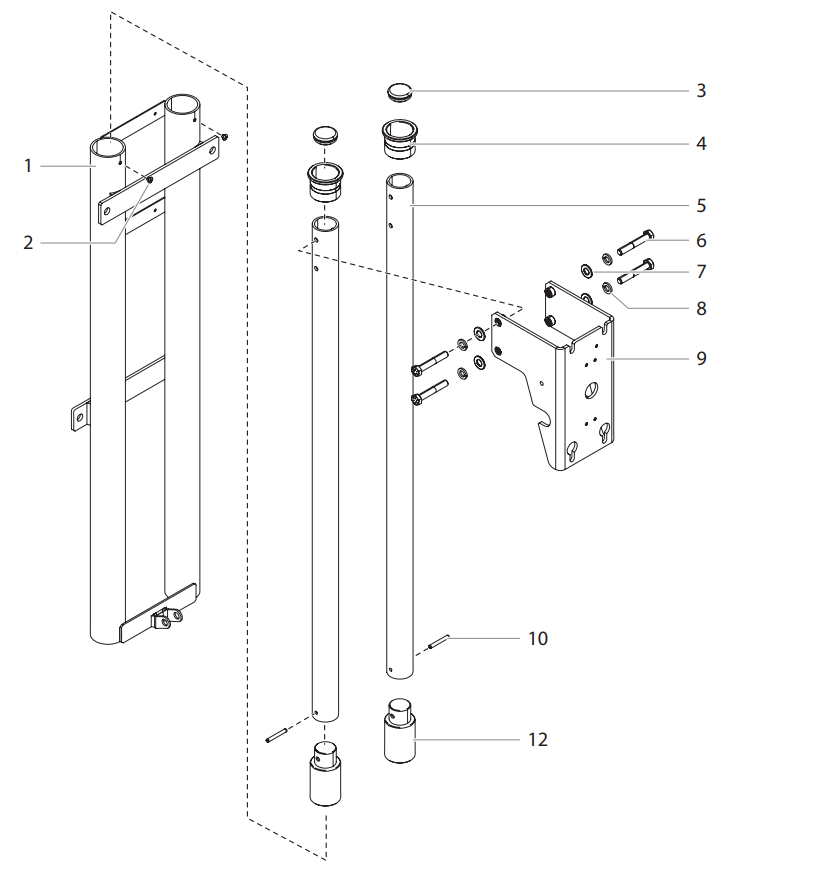

Hydra X (4540,7230) Telescoping Lift Assembly

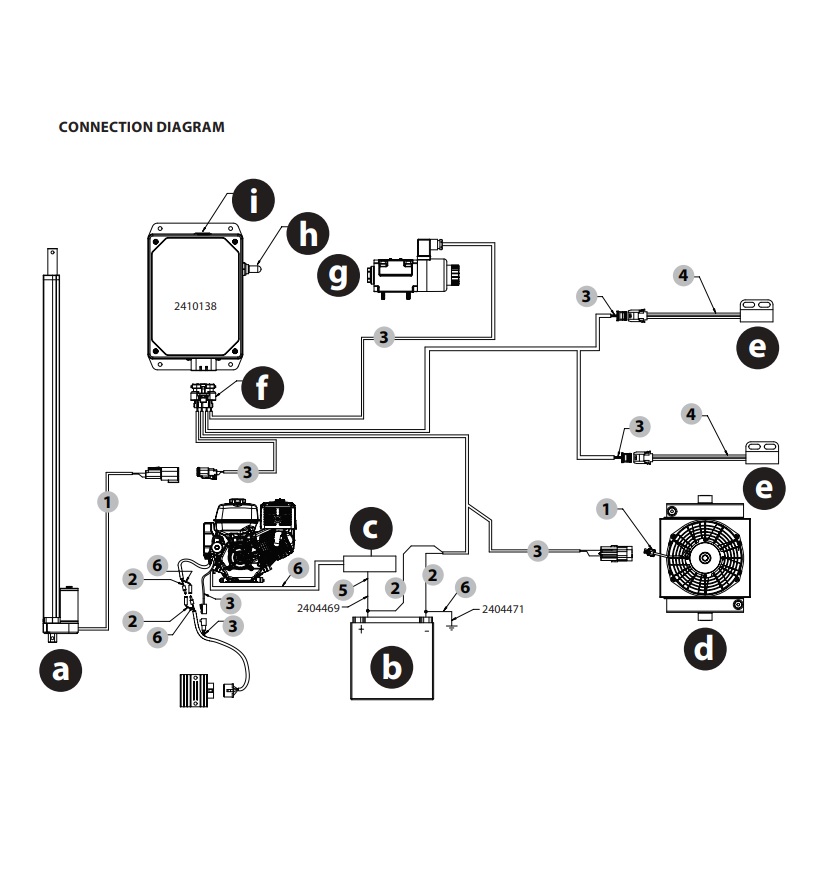

Hydra X (4540,7230) Connection Diagram

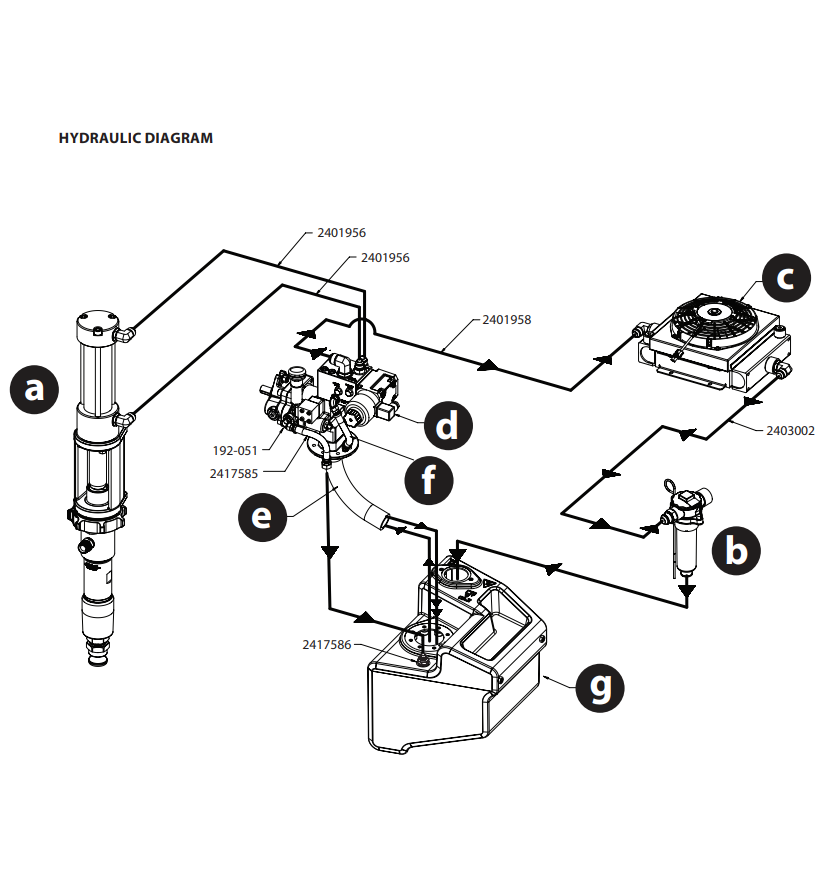

Hydra X (4540,7230) Hydraulic Diagram

Hydra X (4540,7230) Accessories

NEW PRODUCTS FOR FEBRUARY - HYDRA X (4540,7230) PART LIST

The Titan Hydra X 4540/7230 is a high-performance, industrial-grade gas-powered airless sprayer engineered for heavy-duty, high-volume coating applications. Built around Titan’s “HydraStroke®” hydraulic drive technology and a “Severe Service™” fluid section, the Hydra X is designed for contractors and professionals who need reliability and powerful output without sacrificing versatility.

Essentially, this series gives you two performance profiles in one sprayer: the 4540 configuration optimised for high-production work with a 4.0 GPM fluid output, and the 7230 configuration built for maximum pressure (up to 7,200+ PSI) to atomise tough coatings like silicones, epoxies, and elastomeric roof materials.

With its modular fluid-section design (which can be switched between 4540 and 7230), robust hydraulic motor/pump assembly, an AutoLift™ system for effortless drum or pail changes, and heavy-duty build (including dual cooling fans, a large hydraulic fluid reservoir, and rugged 12″ pneumatic tires), the Hydra X stands out as a top choice for demanding commercial, industrial, and roofing jobs.

The Titan Hydra X 4540/7230 is particularly suited for:

Pressure drops, leaking fluid, overheating, and inconsistent spray output are typical symptoms of issues within the Hydraulic System.

Yes. The Hydra X 4540 7230 Main Assembly II is designed for user-friendly servicing, and most parts can be replaced with basic tools.

Yes. The Hydra X Main Assembly II plays a major role in maintaining pressure stability, which directly impacts overall pump efficiency.

While not directly connected to spraying, a stable Hydra X Cart Assembly ensures safe handling and prevents accidental damage to the sprayer.

No. Using the sprayer with a damaged Hydraulic System can cause further mechanical failure and compromise safety.