Subcategories

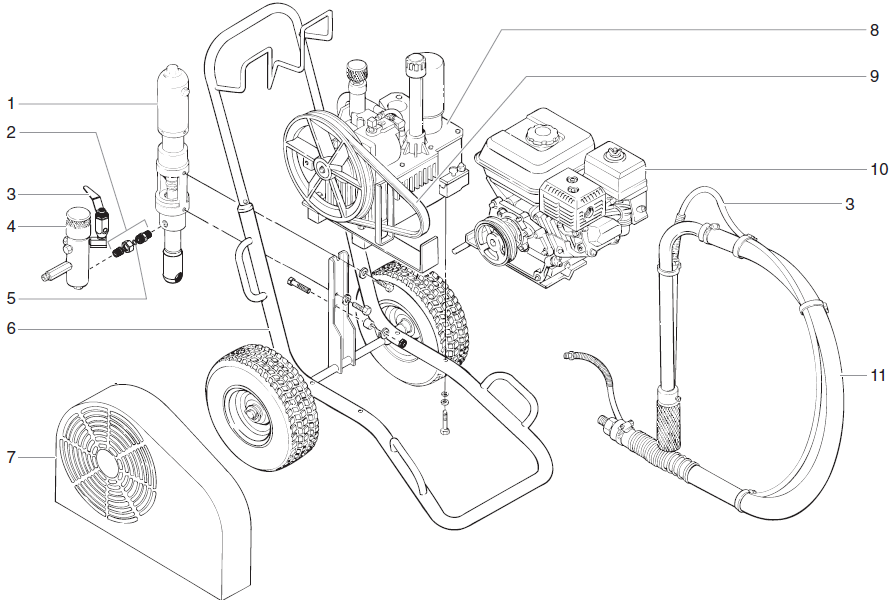

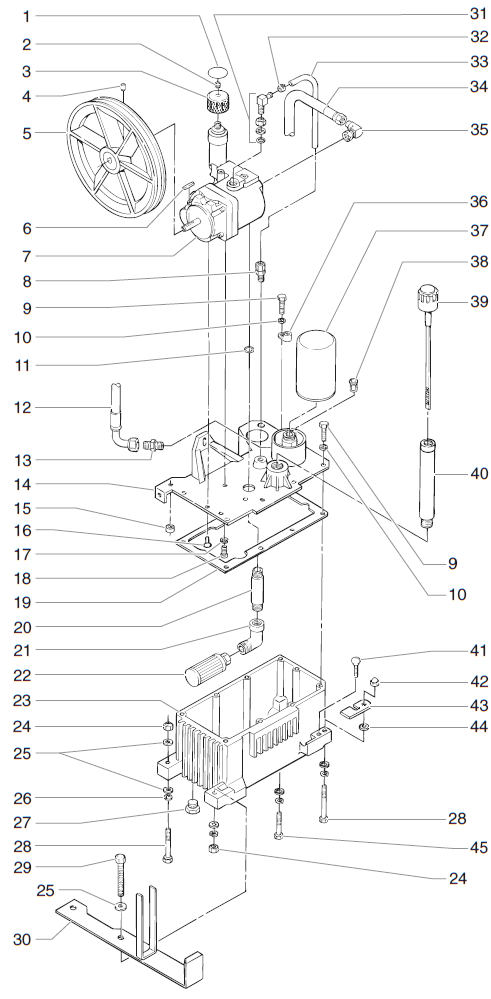

PowrTwin 8900XLT Main Assembly Parts

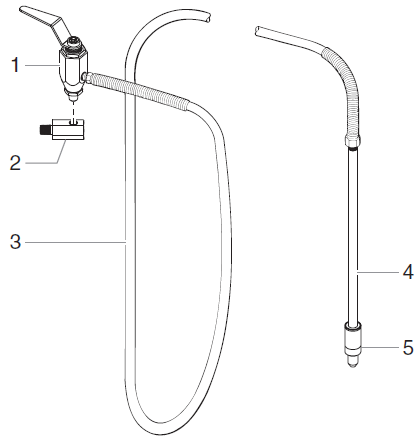

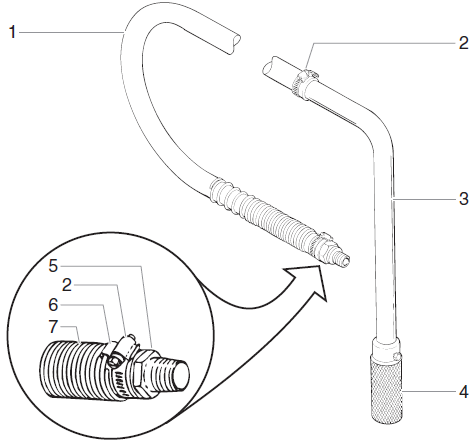

PowrTwin 8900XLT Bleed Hose Assembly With Valve Parts

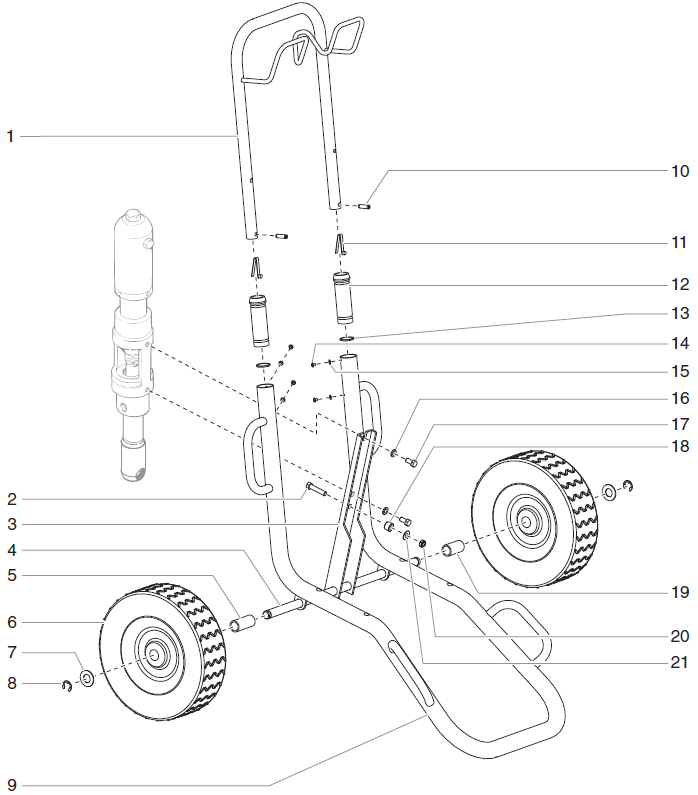

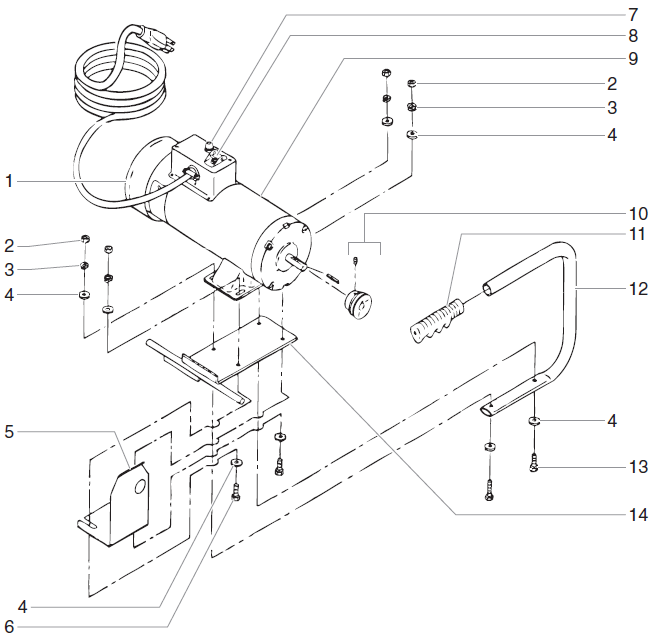

PowrTwin 8900XLT Cart Assembly Parts

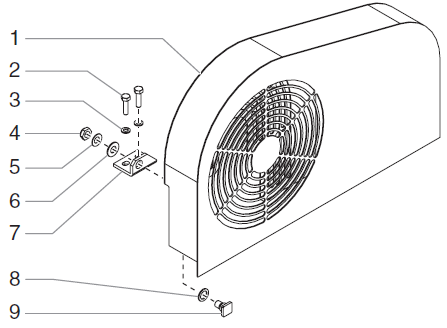

PowrTwin 8900XLT Belt Guard Assembly Parts

PowrTwin 8900XLT Hydraulic System Parts

PowrTwin 8900XLT DC-Electric Convertokit Parts

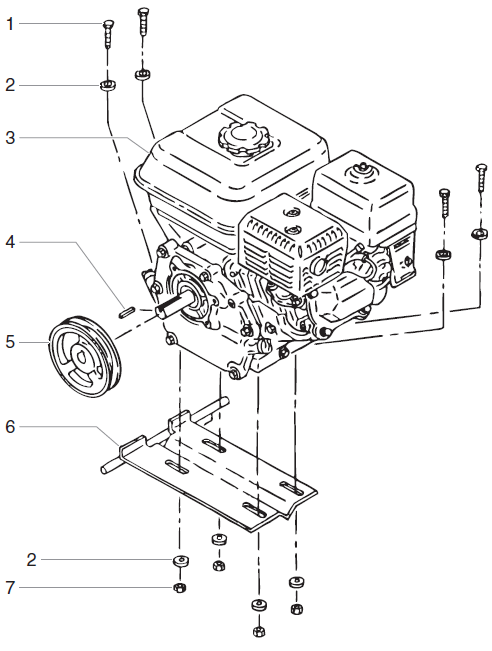

PowrTwin 8900XLT Gas Convertokit Parts

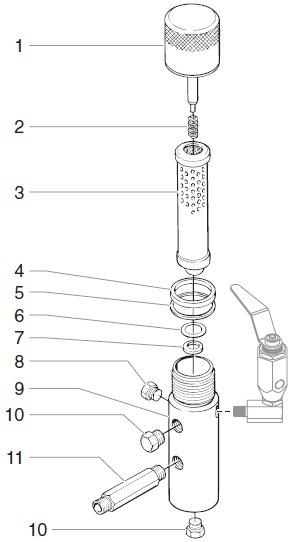

PowrTwin 8900XLT Filter Assembly Parts

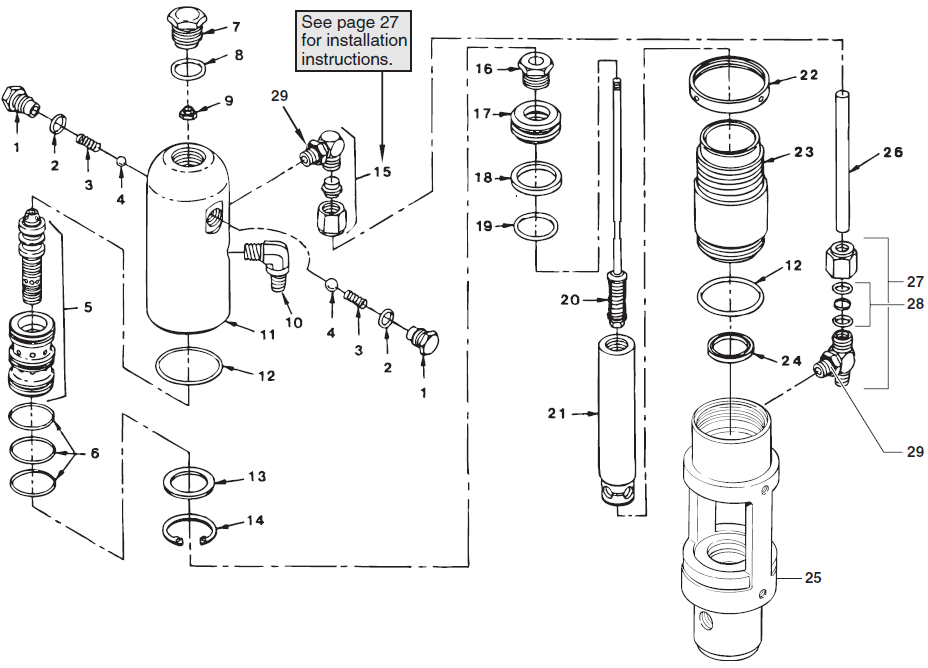

PowrTwin 8900XLT Bleed Valve Assembly Parts

PowrTwin 8900XLT Siphon Hose Assembly Parts

PowrTwin 8900XLT Hydraulic Motor Parts

PowrTwin 8900XLT Fluid Section Parts

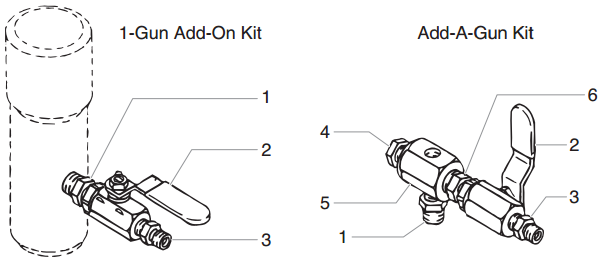

PowrTwin 8900XLT Gun Manifold Assemblies Parts

PowrTwin 8900xlt Accessories Parts

NEW PRODUCTS FOR FEBRUARY - POWRTWIN 8900XLT

The PowrTwin 8900XLT is part of the PowrTwin series sub-category and appears to be a heavy-duty fluid-handling or hydraulic/pneumatic system whose assembly and sub-assemblies are structured into multiple modules main assembly, bleed hose with valve, cart assembly, hydraulic system parts, DC-electric convert kit, gas convert kit, belt guard assembly, filter assembly, bleed valve assembly, siphon hose assembly, hydraulic motor parts, fluid section parts, gun manifold assemblies, and accessories.

This modular breakdown suggests it is designed for versatility offering different build configurations depending on use (e.g. hydraulic, electric-converted, gas-converted, cart mounted, etc.).

Yes ,the product offers a “DC-Electric Convertokit” sub-assembly to enable electric operation.

Yes,there is also a “Gas Convertokit” sub-assembly listed among the parts.

Because the unit is broken into sub-assemblies (hydraulic motor parts, fluid section, filter assembly, valve assemblies), you can replace only the failed module rather than the entire unit reducing downtime and cost.

Valve issues often occur due to dried coating buildup, internal wear of the valve seat, or failure of the internal spring. Operating the sprayer with unfiltered or thick materials can accelerate valve wear, making timely cleaning and inspection essential.

If you notice leaks around the hose fittings, difficulty priming the sprayer, or inconsistent pressure during operation, the bleed hose assembly or its valve may be worn or cracked. Any visible swelling or stiffness in the hose is also a sign that replacement is needed.