Subcategories

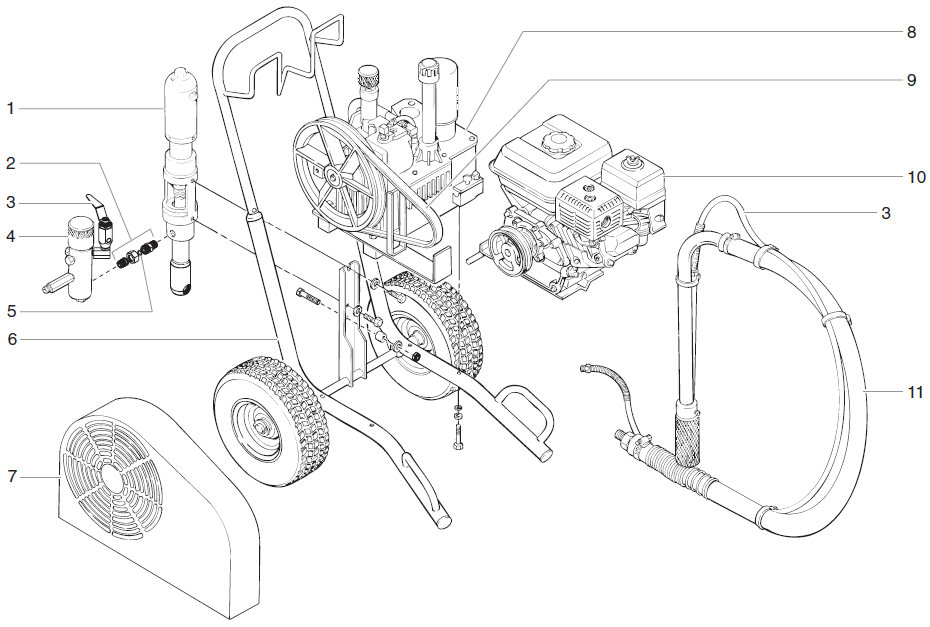

PowrTwin 6900XLT Main Assembly Parts

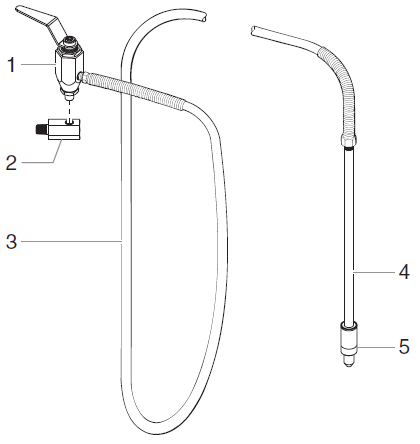

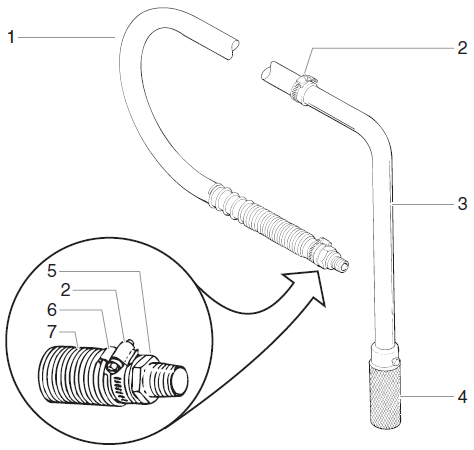

PowrTwin 6900XLT Bleed Hose Assembly With Valve Parts

PowrTwin 6900XLT Cart Assembly Parts

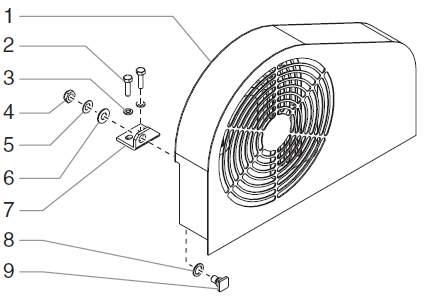

PowrTwin 6900XLT Belt Guard Assembly Parts

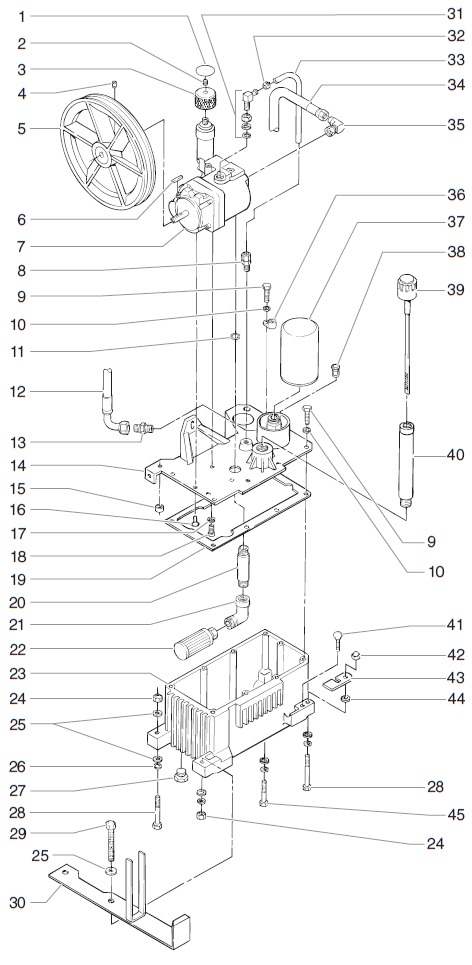

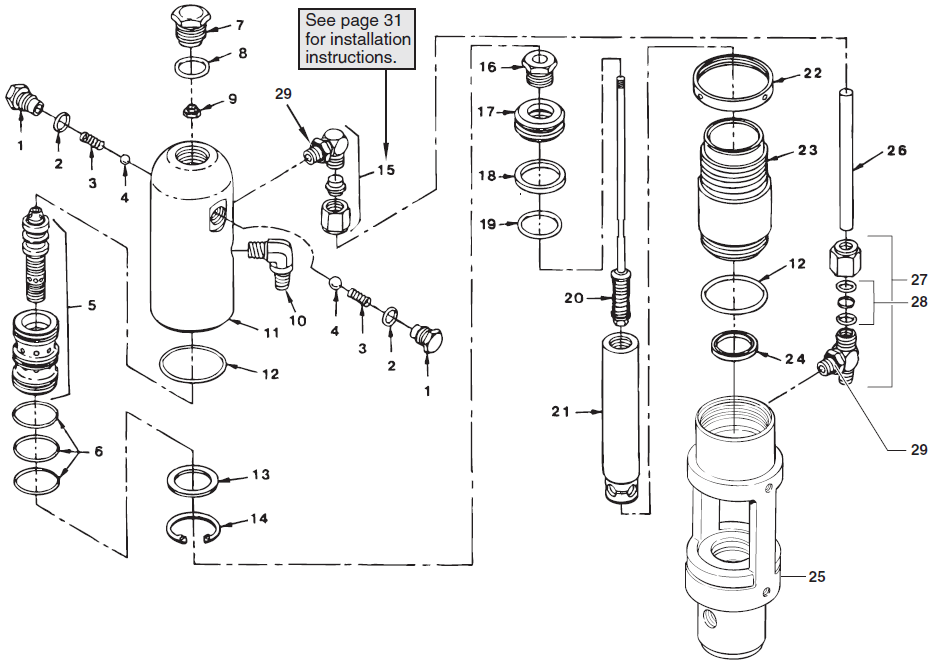

PowrTwin 6900XLT Hydraulic System Parts

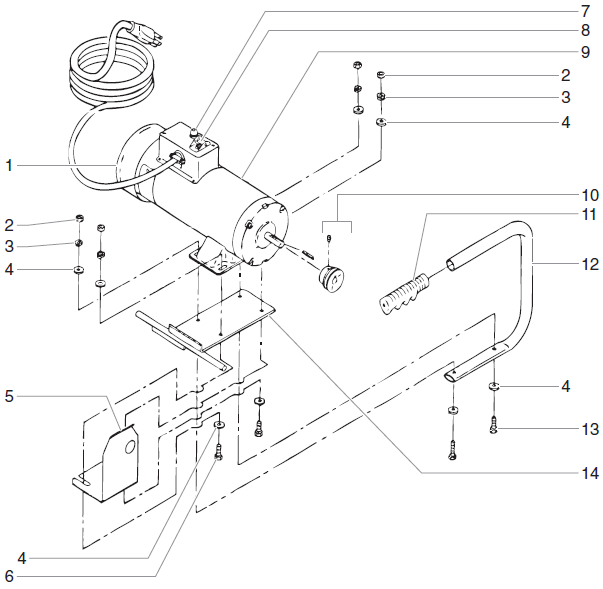

PowrTwin 6900XLT DC-Electric Convertokits Parts

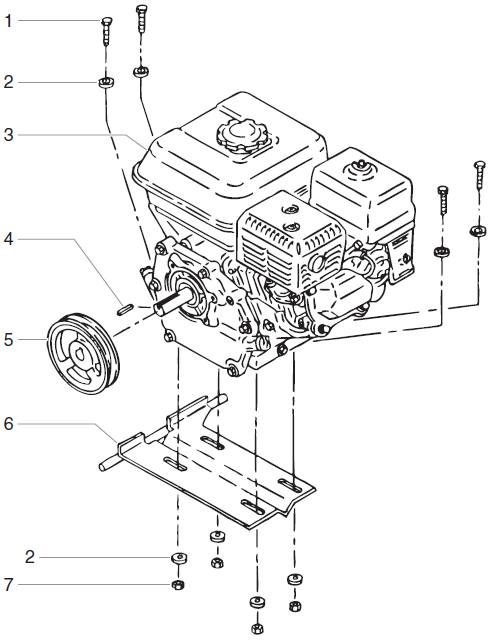

PowrTwin 6900XLT Gas Convertokit Parts

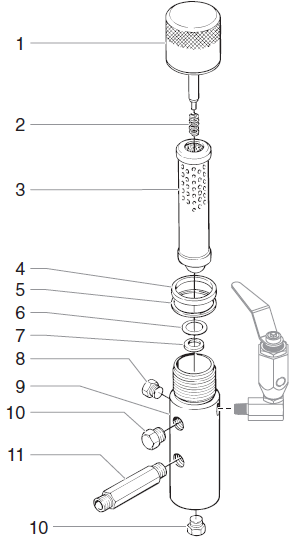

PowrTwin 6900XLT Filter Assembly Parts

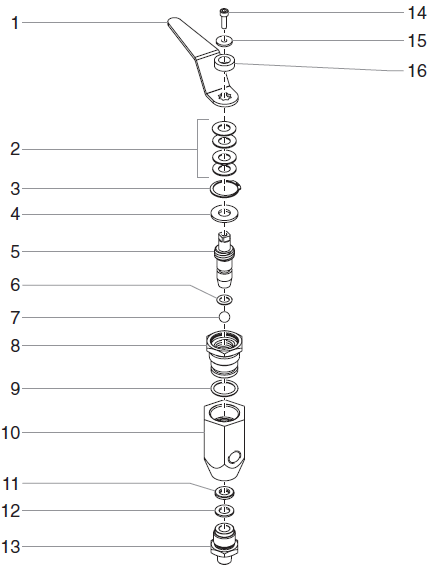

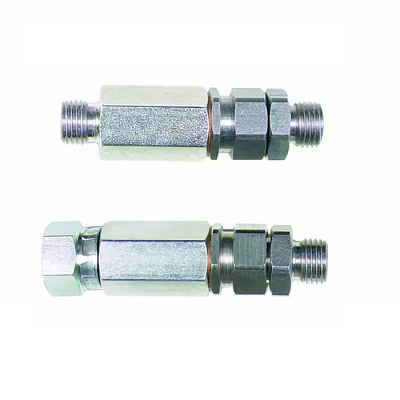

PowrTwin 6900XLT Bleed Valve Assembly Parts

PowrTwin 6900XLT Siphon Hose Assembly Parts

PowrTwin 6900XLT Hydraulic Motor Parts

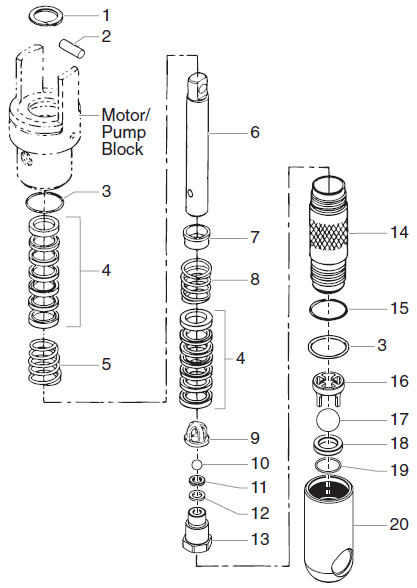

PowrTwin 6900XLT Fluid Section Parts

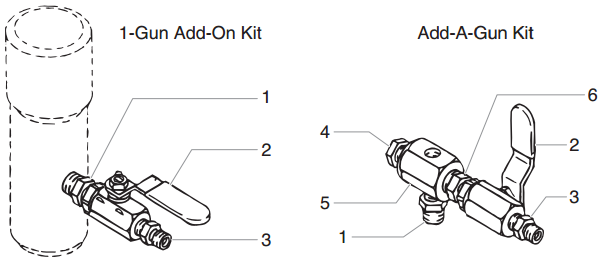

PowrTwin 6900XLT Gun Manifold Assemblies Parts

PowrTwin 6900xlt Accessories Parts

NEW PRODUCTS FOR FEBRUARY - POWRTWIN 6900XLT

The PowrTwin 6900XLT is a heavy-duty hydraulic airless sprayer built for professional and industrial painting jobs that demand high power, consistent pressure, and dependable long-term operation. Designed for contractors and painting crews handling large commercial, industrial, or high-volume residential projects, the 6900XLT uses a hydraulic drive system to deliver stable, high-pressure fluid flow, enabling efficient spraying of a wide range of coatings from thin primers to thick block-filling or textured materials. Its design emphasizes durability, field-serviceability, and modular maintenance.

With its robust fluid section, hydraulic motor/pump block, siphon or hopper inlet options, bleed and flush valve assemblies, and optional gas- or electric-drive configurations, the 6900XLT is appropriate for demanding work environments, long hose runs, and extended spray times. It’s engineered both for heavy coatings and for contractors who need reliability and minimal downtime on job sites.

The PowrTwin 6900 XLT uses a proprietary double-ball piston pump built with thick stainless-steel rods and cylinders that have undergone a special heat-treating process, making them highly abrasion-resistant and corrosion-resistant.

This design reduces friction, extends packing life, and ensures the pump holds up under heavy use; many of these pumps have been in service worldwide for decades.

The unit provides flexibility: it can operate on gas engine power or electric motor power, depending on the model/version you choose. This allows you to use it outdoors (gas) or indoors/where electricity is available (electric).

Maximum operating pressure: 3300 PSI (22.8 MPa / ~228 bar). For the electric version, flow rate is 1.25 gallons per minute (GPM) (≈ 4.7 L/min), while for gas/hydraulic versions, flow and tip-size may vary depending on configuration. Maximum spray tip sizes vary depending on whether you use one gun or multiple guns. Ensure you follow manufacturer guidelines.

A pressure drop often indicates an issue within the Hydraulic System. Worn hydraulic seals, contaminated hydraulic oil, or a failing hydraulic motor can cause reduced output. Replacing the damaged Hydraulic System Parts and ensuring the hydraulic fluid is clean and at the correct level typically restores performance.

The unit provides flexibility: it can operate on gas engine power or electric motor power, depending on the model/version you choose. This allows you to use it outdoors (gas) or indoors/where electricity is available (electric).