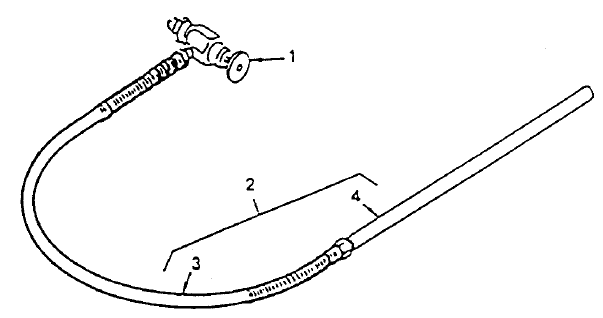

Part #: 944-620

Part #: 103-111

Part #: 539-078

Part #: 103-117

Keep your PowrTwin 3500 operating safely and efficiently with our genuine Bleed Line Assembly With Valve components. This sub‐category covers the essential bleed line and valve assemblies that allow you to relieve pressure, flush the system and maintain safe operation of your sprayer. With correct parts, you’ll ensure reliable purge, proper pressure release and longer machine life.

Explore the key items in this sub-category (each item links to its product page for full specifications and purchase):

Pro Tip: If you’re experiencing difficulties with pressure relief, flushing, or suspect the bleed line is blocked or leaking, inspect the valve (# 944-620) and the hose/tube assembly for damage or wear.

Here’s how to select the correct part for your PowrTwin 3500:

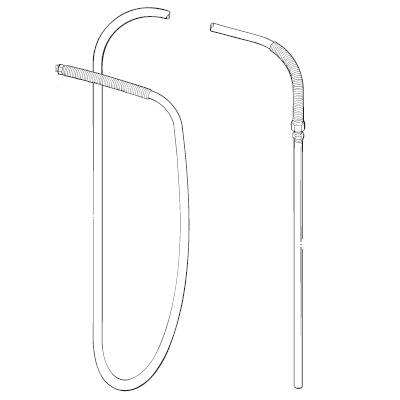

This category includes the bleed line tubing/hose assemblies and the bleed valve units that form the pressure-relief path on the PowrTwin 3500 — such as parts # 944-620, # 103-111, # 103-117, # 539-078.

The bleed line assembly provides a safe path to relieve pressure when servicing or shutting down the machine, and also facilitates flushing of fluid from the system. Without it functioning properly, you risk trapped pressure, leaks, or damage when servicing.

If the valve leaks or fails to open/close properly, replacing just the valve (# 944-620) may suffice. If you notice damaged tubing, cracked hoses or degraded fittings in the bleed line path, then replacing the full assembly (# 103-111) is recommended.

While it might be possible, using non-OEM components risks incorrect pressure ratings, potential leaks or misfit, and may void machine's warranty or compromise safety. Genuine Titan bleed line assemblies ensure the correct materials and fit.

It should be inspected regularly as part of routine maintenance — look for wear, hose bends/kinks, corrosion, leaks or difficulty bleeding. If any issue is found, replace the valve or full assembly immediately to maintain safe operation.

Browse our full collection of PowrTwin 3500 bleed line assemblies and valves above and find the exact part you need. If you’re unsure which part number fits your machine, contact our support team — we’ll help you identify the correct item and restore safe operation of your sprayer.