Part #: 944-024

Part #: 944-004

Part #: 944-026

Part #: 945-003

Part #: 944-904

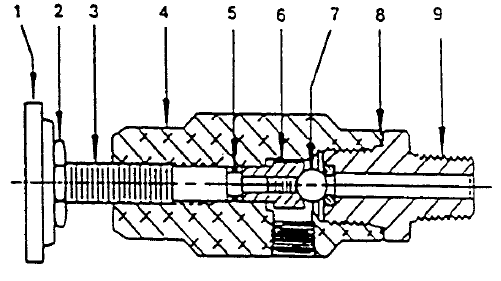

Ensure your PowrTwin 3500 sprayer remains safe, serviceable and efficient with our genuine Bleed Valve Assembly components. This sub-category covers the critical valve assemblies that allow you to relieve system pressure, flush the machine after use, maintain safe operation and protect both equipment and operator.

Here are some of the key items in this sub-category (each links to its product page for specs & purchase):

Pro Tip: If your sprayer refuses to relieve pressure, you notice leaks from the valve port, or you have difficulty flushing, inspect the bleed valve assembly parts above — replacing the correct component often restores safe operation quickly.

Here are steps to guide your part selection:

This covers all parts related to the bleed valve mechanism on the PowrTwin 3500 — including the knob, seat, stem stop, O-ring/gasket and associated hardware required for pressure relief and system flushing.

Because the sprayer operates at high pressures (up to 3000 psi for many models) the bleed valve enables safe depressurising, proper flushing and maintenance operations. Without a functioning bleed valve you risk trapped pressure, leaks or damage.

If the valve does not turn freely, fails to relieve pressure, or you detect visible leaks, the assembly may be faulty. If operation is fine but you see a minor leak at the connection, replacing the gasket or O-ring may suffice.

Using aftermarket parts is possible but not always recommended: OEM parts offer precise fit, correct materials (e.g., tungsten seat) and compatibility with the system’s high-pressure rating. Using inferior parts may compromise safety, performance or durability.

Bleed valves should be inspected during regular maintenance—check for smooth operation, leaks, full turn-range, and correct seating. If you detect weakness, delay or leakage during pressure relief, plan for replacement immediately.

Browse our full collection of PowrTwin 3500 bleed valve assembly components above and select the exact part you need. If you’re unsure about which part number or version suits your machine, contact our support team — we’ll help you identify the correct item and restore safe and reliable operation of your sprayer.