Subcategories

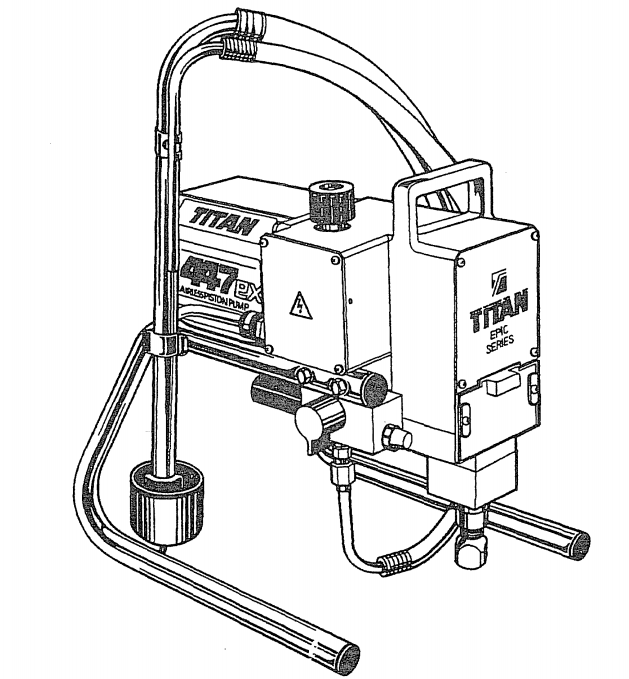

NEW PRODUCTS FOR FEBRUARY - EPIC 447EX

For professional painters who demand accuracy and longevity, the Epic 447EX is a strong and effective airless sprayer. Important parts like the Epic 447EX Gear Box and Epic 447EX Filter Block must be maintained in order to keep it operating smoothly. We provide a wide selection of authentic replacement parts at AllTitanParts.com to guarantee your sprayer keeps operating at its peak efficiency. Using high-quality parts helps your equipment last longer and avoid unplanned malfunctions.

The sprayer runs smoothly and reliably thanks to the excellent power transmission provided by the Epic 447EX Gear Box. Timely replacement of a worn-out gear box is essential since it can result in reduced performance and increased wear on other components. Similarly, by keeping debris out of the system, the Epic 447EX Filter Block is essential to keeping the paint flow clean. Reliable operation and a perfect finish are ensured by routine maintenance and replacement of these parts using authentic parts from AllTitanParts.com.

We make it simple to locate and purchase the appropriate Epic 447EX components at AllTitanParts.com. Whether you require the Epic 447EX Filter Block or the Gear Box, our large selection guarantees that you may find high-quality alternatives. To maintain the best possible condition for your sprayer, visit our website right now!

After every major use of Epic447HPX, flush the system fully with the appropriate cleaning solution (water for latex, solvent for oil-based) to prevent buildup in the fluid section and spray gun. Cleaning immediately after use helps prevent clogs and maintains part lifespan.

Before each use, inspect hoses, connections, filters, and the spray tip for wear or damage. Tighten fluid fittings, check the pressure control, and ensure the electric motor and brushes are in good condition.

If spray patterns become uneven, sputtering occurs, or there’s reduced pressure delivery, filters or fluid components may be clogged or worn and should be cleaned or replaced.

Inspect hoses before every job for cracks, kinks, or damage. Replace any weakened sections and always use hoses rated for the system’s working pressures to avoid leaks and pressure injuries.

Maintain good ventilation around the motor, avoid prolonged dry running without fluid, check motor brushes periodically, and ensure power supplies are stable to reduce wear.