Subcategories

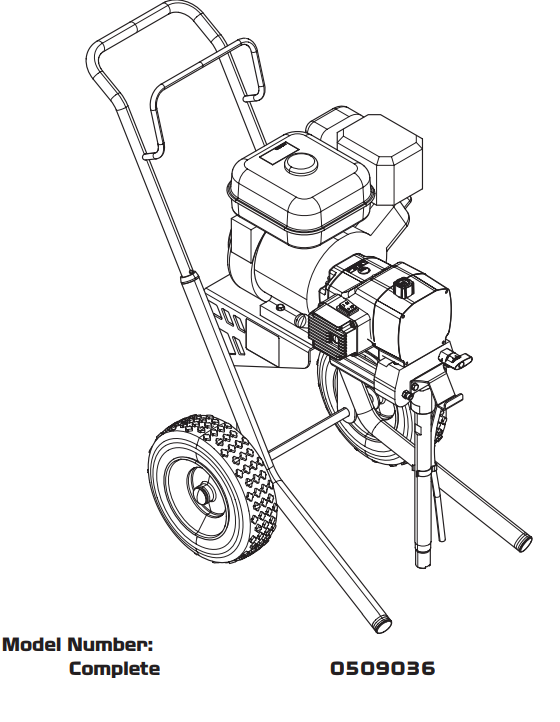

NEW PRODUCTS FOR FEBRUARY - GPX 85 GAS PISTON PUMP

The GPX 85 Gas Piston Pump is a high-performance, gas-powered airless sprayer pump engineered for contractors who need consistent pressure, excellent atomization, and long-lasting durability. Built for demanding on-site jobs, this pump delivers reliable flow for spraying a wide range of coatings—making it ideal for residential, commercial, and light industrial work.

Designed with a rugged piston system, precision fluid section, and durable seals, the GPX 85 provides smooth operation and reduced downtime. Its simple construction allows easy servicing, quick replacement of wear parts, and dependable performance in tough environments.

Reliable power output for spraying in areas without electricity.

Consistent pressure for uniform coating application.

Durable piston pump ensures steady flow and smooth spraying.

Optimized for thicker materials and large surfaces.

Modular assemblies allow quick tear-down and part replacement.

Wear items such as seals, packings, siphon tubes, and filters can be replaced easily.

Built to withstand heavy use with premium-grade components.

Corrosion-resistant materials extend pump lifespan.

Handles primers, latex paints, acrylics, enamels, and other contractor-grade coatings.

Can be paired with sturdy cart assembly parts for easy transport around job sites.

The GPX 85 Gas Piston Pump is ideal for:

The piston packings on the GPX 85 Gas Piston Pump usually need to be replaced every 3 to 6 months, depending on how frequently the sprayer is used and the type of coatings applied. When you notice symptoms such as uneven pressure, leakage around the pump, or an unstable spray pattern, it’s a clear indication that the packings are worn and need replacement.

If the pump begins to lose pressure, produces a pulsating spray, struggles to prime, or starts leaking paint around the lower pump area, these are signs that the fluid section components are worn out. At that point, servicing the valves, seals, and internal components becomes necessary to restore smooth performance.

After every job, the pump should be flushed thoroughly with either water or solvent, depending on the coating used. The filters should be cleaned, the hoses inspected, and the pump lubricated. This routine prevents material buildup and ensures that the GPX 85 performs consistently for a longer period.

The GPX 85 parts that generally require replacement most frequently are the siphon hose, the inlet and outlet valves, seals, O-rings, and the piston packings. These components are exposed to constant pressure and material flow, so they naturally wear out faster and need timely replacement to avoid major breakdowns.

You should replace the siphon hose or siphon set whenever you observe cracks, stiffness, clogging, or reduced suction during priming. A damaged siphon hose can affect the pump’s ability to draw material properly, leading to weak performance or air leaks during operation.