Part #: 0537244A

- 0538014.jpg)

Part #: 0538014

Part #: 651-020

Part #: 0297007

Part #: 0289122

Part #: 697-419

Part #: 2408355

Part #: 2410679

Part #: 2424122

Part #: 860-552

Part #: 756-088

Part #: 980-332A

Part #: 756-088

Part #: 860-002

Part #: 0509538

Part #: 9811122

Part #: 0521229

Part #: 316-505

Part #: 0537740

Part #: 537727

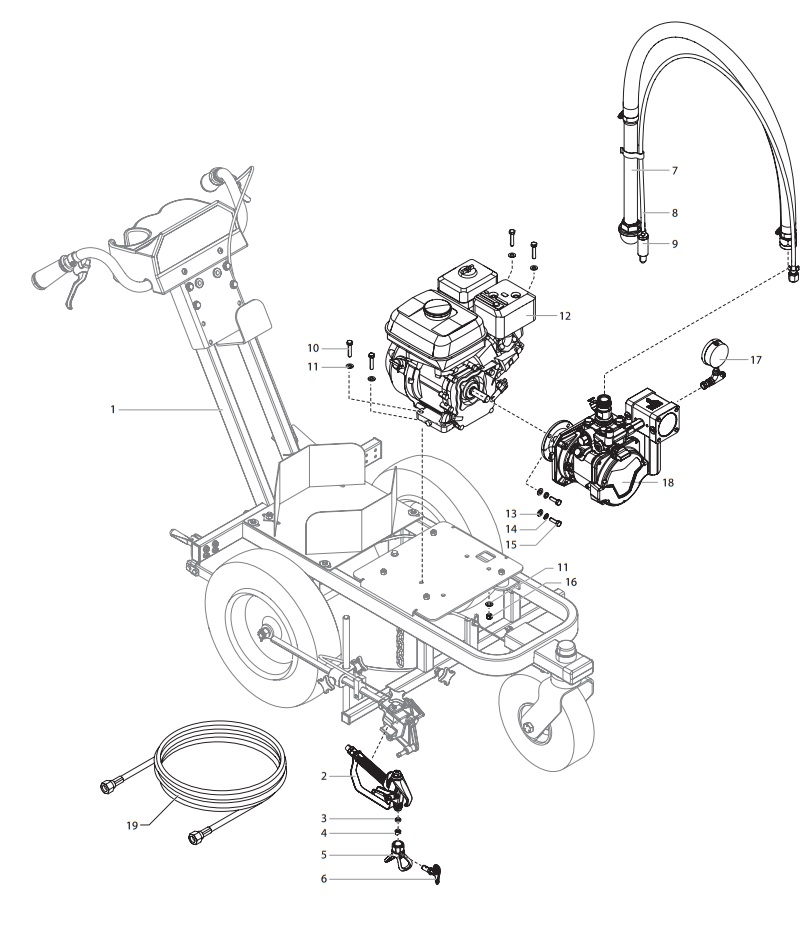

The PowrLiner 3500 Main Assembly Parts are essential for maintaining the performance, safety, and reliability of the Titan PowrLiner 3500 line striping machine. Designed for professional contractors and maintenance crews, these genuine Titan components help restore factory-level operation while ensuring consistent pressure, accurate striping, and dependable machine control on demanding job sites.

This main assembly includes critical operational and identification components such as the Titan 0521229 Gauge Assembly, Titan 860-002 Lock Washer, Titan 537727 Relief Valve Label, Titan 0537740 Front Cover Label, and the Titan 316-505 50’ Spray Hose. Each part plays a vital role in pressure monitoring, system safety, fluid delivery, and proper machine identification.

Using OEM Titan parts ensures exact fitment, proper pressure ratings, and long-term durability. Whether you are replacing worn components or performing scheduled maintenance, PowrLiner 3500 main assembly parts help reduce downtime and keep your line striping machine operating at peak efficiency.

The Titan 0521229 gauge assembly monitors fluid pressure during operation. Accurate pressure readings help prevent over-pressurisation, ensure consistent spray output, and protect internal components from damage.

The Titan 316-505 50’ spray hose should be replaced if you notice paint leaks, pressure loss, surface cracking, or reduced flexibility. A worn hose can affect spray consistency and compromise job-site safety.

The Titan 860-002 lock washer helps prevent fasteners from loosening due to vibration during operation. Replacing worn or damaged lock washers ensures components remain securely fastened and aligned.

While these labels do not impact mechanical performance, they are critical for safety awareness, proper identification, and compliance. Replacing damaged or missing labels ensures operators can quickly identify controls and safety features.

Yes, during routine maintenance or repairs, replacing related components together, such as the gauge assembly, spray hose, and fastening hardware, can improve reliability, reduce future downtime, and restore the PowrLiner 3500 to optimal working condition.