Subcategories

NEW PRODUCTS FOR FEBRUARY - IMPACT 400 AIRLESS SPRAYER

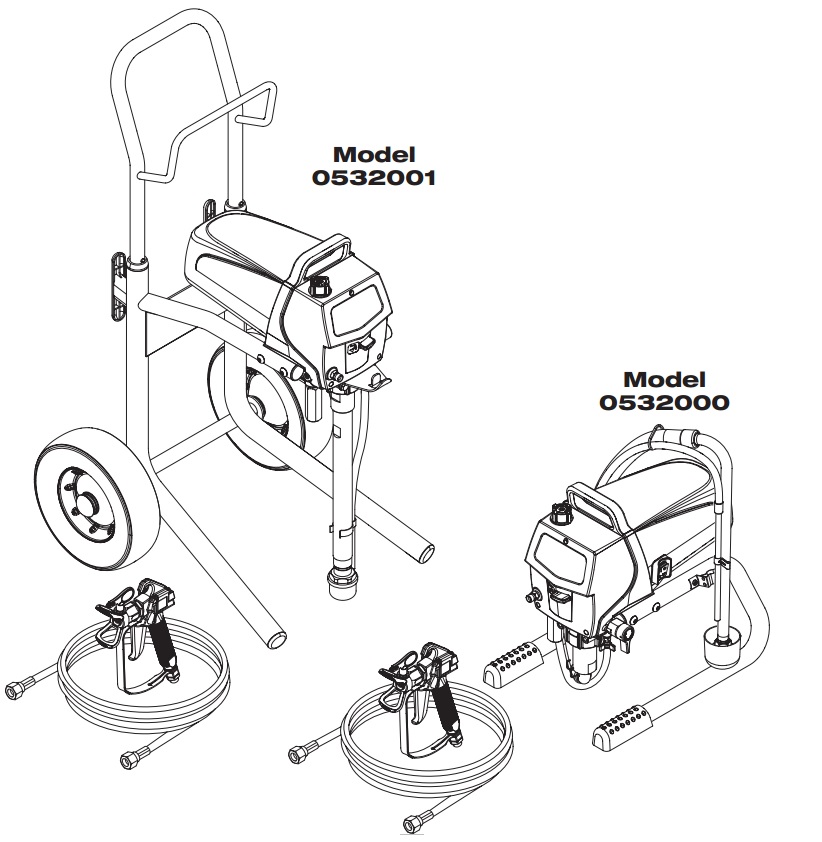

Titan IMPACT 400 AIRLESS SPRAYER a perfect tool for residential, property maintenance, and small commercial painting needs. This high-performance electric airless sprayer is designed to apply all standard architectural primers, paints, and coatings efficiently, giving you a smooth and professional finish.

The Titan Impact 400 Electric Airless Sprayer can spray various coatings, including stains, lacquers, enamels, latex, and other low and medium-viscosity coatings. With a maximum delivery of 0.47 GPM or 1.78 LPM and a maximum operating pressure of 3000 PSI or 20.7 MPa, this sprayer is perfect for completing your painting projects quickly and easily.

The maximum tip size of 0.021" for one gun and electric operation makes Titan Impact 400 Electric Airless Paint Sprayer versatile and adaptable to various applications. If you're looking for a powerful, reliable, and efficient airless sprayer for your residential, property maintenance, or small commercial painting needs, the Titan IMPACT 400 AIRLESS SPRAYER is perfect. Order Impact 400 from AllTitanParts today and see the difference it can make in your painting projects.

FAQS

The Drive Assembly section includes parts that transmit power from the motor to the pump such as gears, couplings, drive shafts, mounting hardware, and tie-down elements ensuring the sprayer’s drive train functions properly.

The Impact Accessories 400 & Cart / Mounting section offers supporting components such as upgraded carts (high-rider or low-rider), wheels, rubber feet, drip cups, handles, mounting brackets, and other jobsite-friendly add-ons designed to increase the versatility and mobility of the Impact 400.