Subcategories

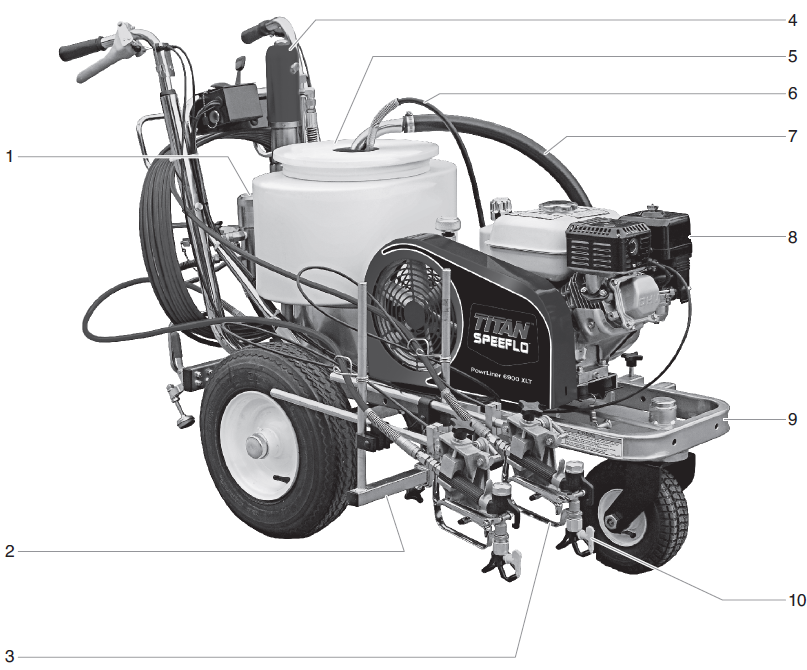

PowrLiner 6900XLT Main Assembly — Gas Model

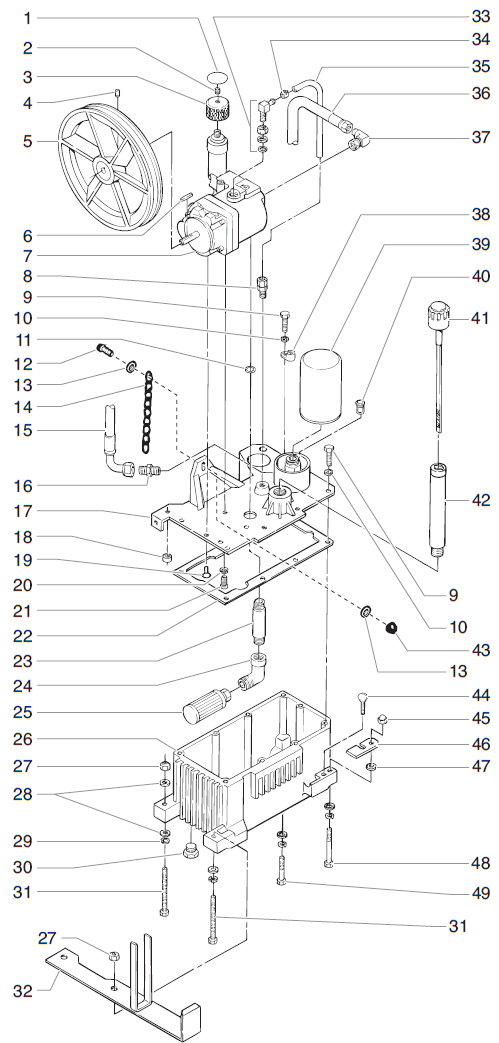

PowrLiner 6900XLT Hydraulic System Assembly (P/N 779-128)

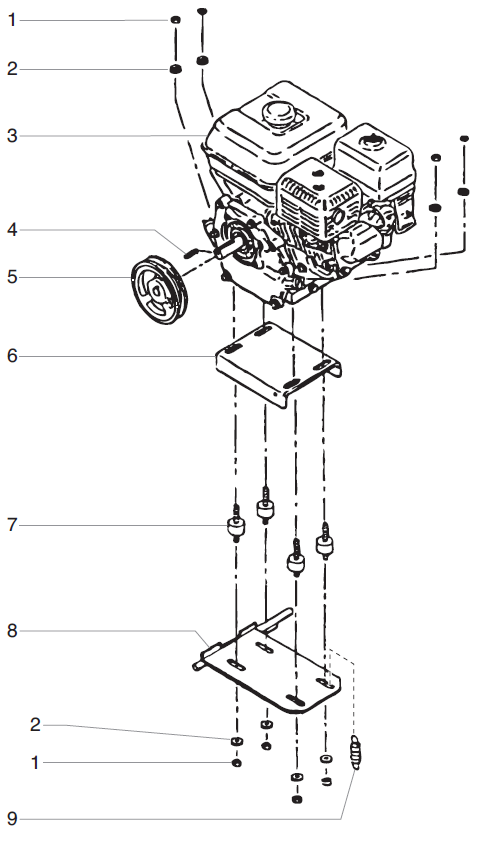

PowrLiner 6900XLT Gas Convertokit (P/N 506-146)

PowrLiner 6900XLT DC — Electric Convertokits

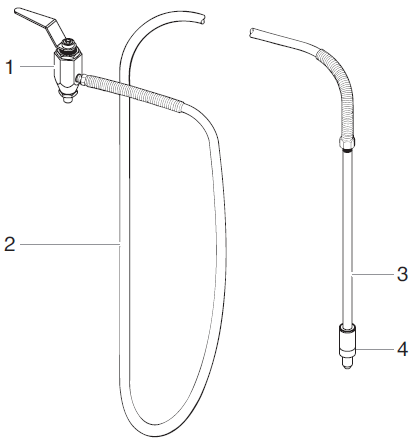

PowrLiner 6900XLT Siphon Hose Assembly (P/N 103-842)

PowrLiner 6900XLT Bleed Hose Assembly with Valve

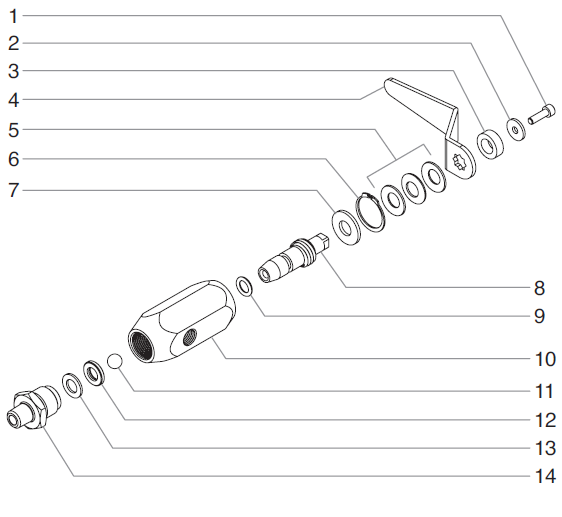

PowrLiner 6900XLT Bleed Valve Assembly (P/N 944-030)

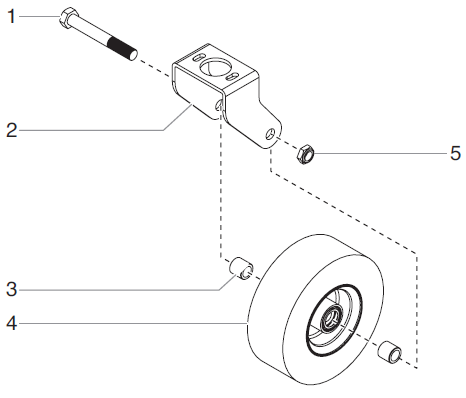

PowrLiner 6900XLT Wheel Assembly

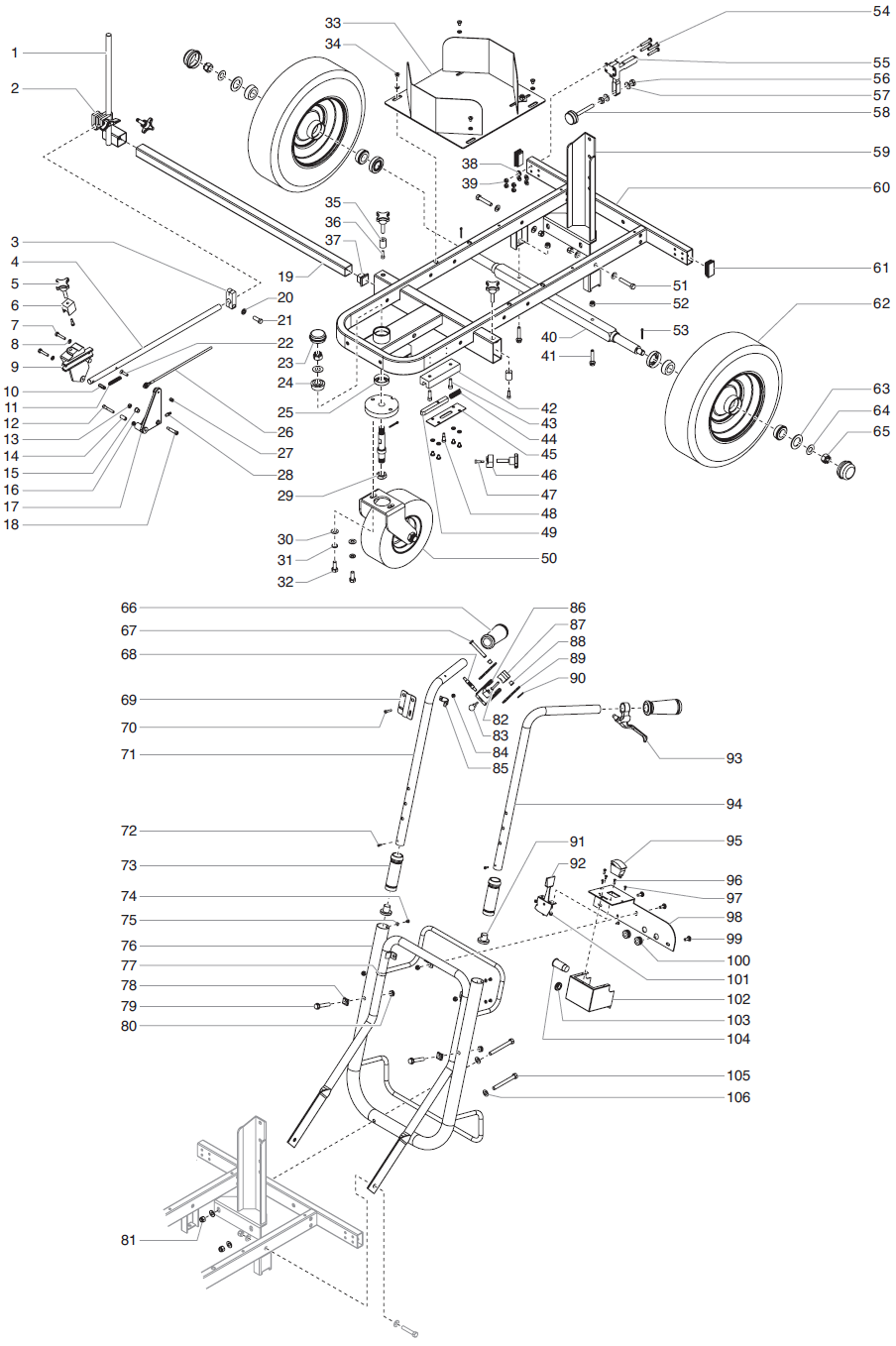

PowrLiner 6900XLT Cart Assembly (P/N 779-564)

PowrLiner 6900XLT Hydraulic Motor

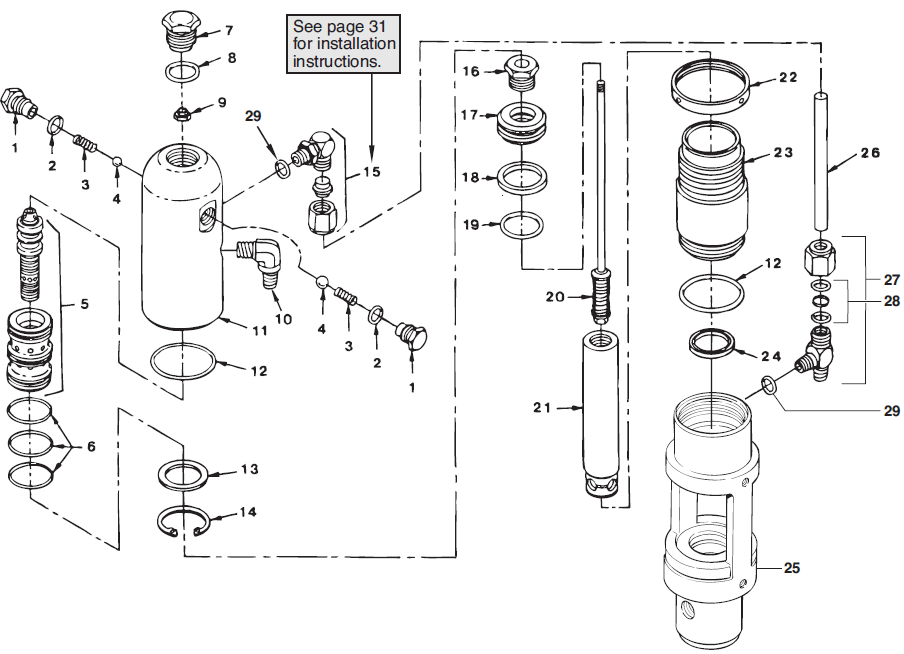

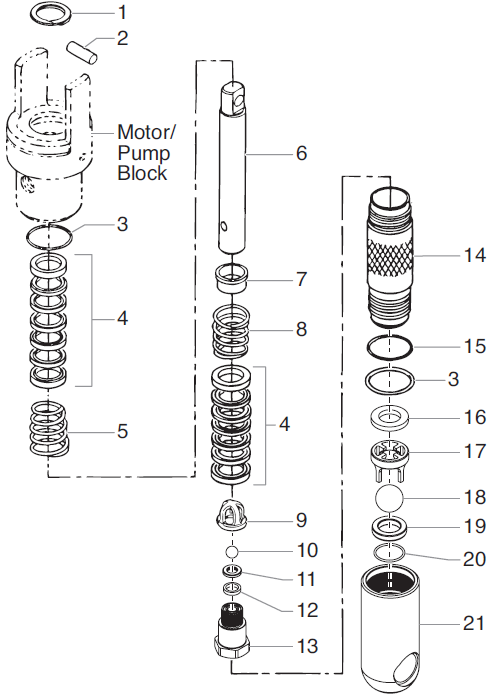

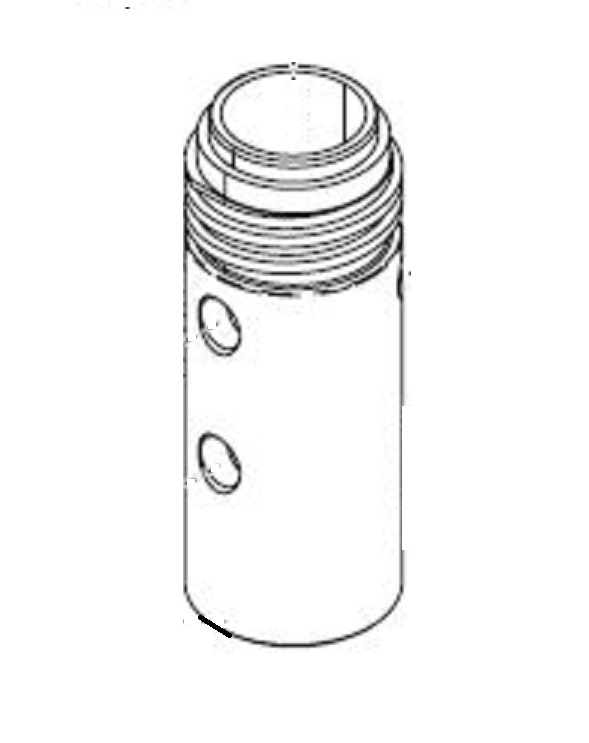

PowrLiner 6900XLT Fluid Section

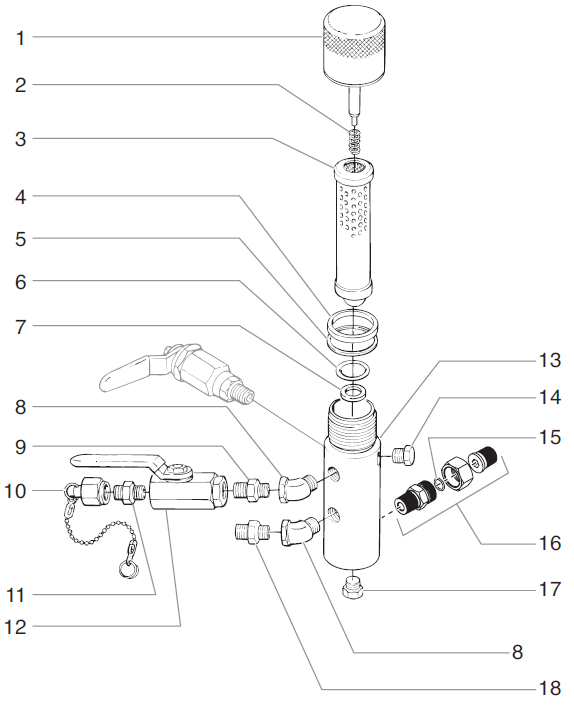

PowrLiner 6900XLT Filter Assembly (P/N 779-098)

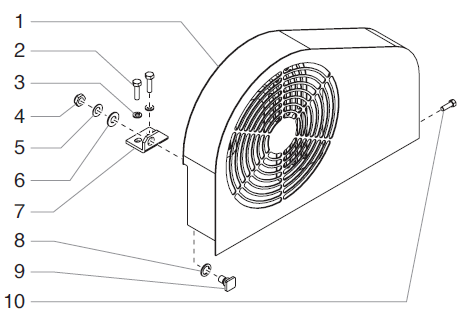

PowrLiner 6900XLT Belt Guard Assembly (P/N 449-925)

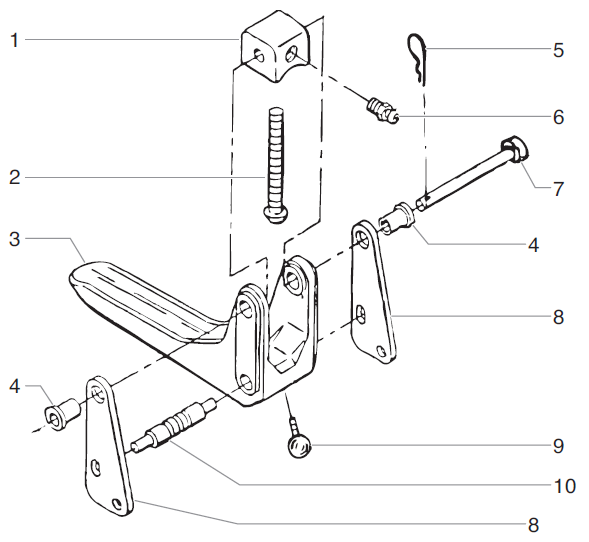

PowrLiner 6900XLT Trigger Assembly

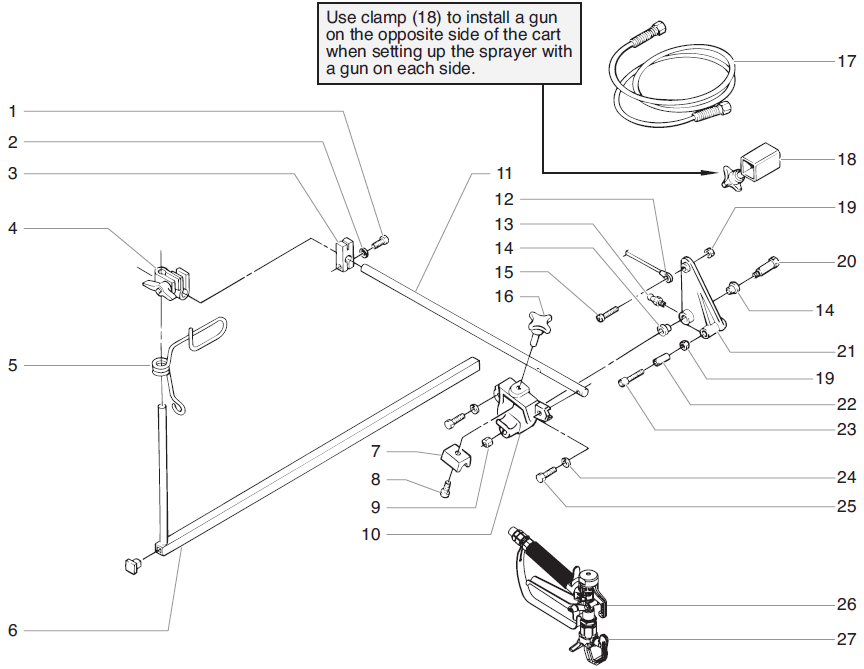

PowrLiner 6900XLT Second Gun Assembly

Accessories

NEW PRODUCTS FOR FEBRUARY - SPEEFLO POWRLINER 6900XLT

The PowrLiner 6900XLT is a top-of-the-line, heavy-duty hydraulic line-striping machine built for professionals who demand reliability, power, and precision on big marking jobs. Whether you’re striping parking lots, roadways, airports, industrial zones, or sports complexes, this unit is engineered to deliver crisp lines, consistent spray pressure, and long service life. With its robust engine, high-capacity paint hopper, and flexible power options (gas or electric), the 6900XLT is not just a tool; it’s a dependable workhorse that helps contractors get big jobs done efficiently with minimal downtime.

Built around a rugged, epoxy-finished frame and a powerful hydraulic system, this model brings together durability, versatility, and performance. It suits contractors working full-time on large-scale striping projects who need a machine that performs at high output without compromising on quality, control, or longevity.

The PowrLiner 6900XLT is well-suited for heavy-duty striping and marking tasks such as:

This covers components such as the hydraulic motor, drive belts and guards, pumps, pumps’ hydraulic fittings, and all hardware needed to power the fluid pump. The hydraulic system ensures smooth, controlled paint flow and long pump life, which is critical for consistent spray quality and fewer maintenance issues.

If spray pressure becomes inconsistent, flow weakens, or spray nozzles clog, this may signal worn or clogged filters, valves, seals, or fluid-path components. Periodic inspection and maintenance (or replacement) prevent clogs, ensure smooth paint delivery, and avoid pump strain.

This covers parts needed to convert the unit’s power source from gas to electric (or vice versa). This flexibility is useful when working indoors, in emission-sensitive areas, or job sites where noise and fuel fumes must be minimized.

Installing a second gun is helpful when you want to spray dual or wider lines in a single pass for example, double-lane markings, wide parking stalls, or long road projects. This improves productivity and ensures uniform striping across wide surfaces.

Regularly check hydraulic fluid and hoses, inspect and clean filters, verify seals and packings, keep the paint fluid clean and free of debris, and lubricate moving parts. Also, ensure proper paint consistency and pressure settings for the type of coating used. Proper upkeep will extend pump life, maintain consistent line quality, and reduce downtime.