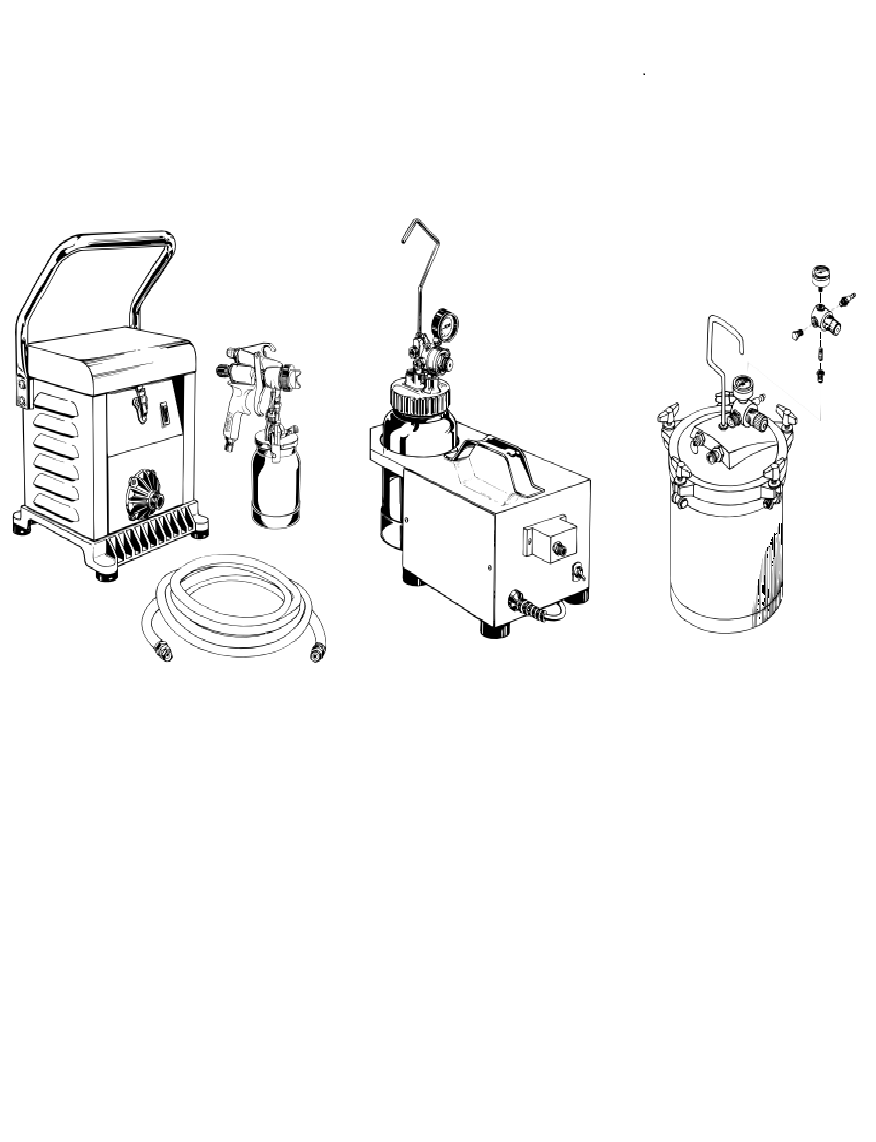

Profinish TS / TSR /TSP Sprayer parts

The ProFinish TS / TSR / TSP series delivers a professional‑grade HVLP turbine spray setup, designed for contractors, finishers, and painting professionals who need reliable performance across a variety of coatings and project sizes. The lineup includes:

- The Pro-Finish TS40 / TS50 Turbine — a compact turbine unit for HVLP spraying.

- ProFinish TSR Compressor System / 2‑Quart Remote — a version with remote cup capability, giving extra material capacity and flexibility for extended tasks.

- ProFinish TSP Cart Assembly — a cart‑mounted configuration combining turbine, compressor, pressure pot, and all required components for larger jobs or frequent mobility.

- Associated assemblies and accessories such as ProFinish Compressor Assembly, ProFinish Pressure Pot Assembly (770‑565), and ProFinish 773‑140 Quart Cup Assembly — enabling a full-pressure-feed or remote‑cup HVLP system.

Key Features

- Modular system with multiple configurations — Whether you choose the basic turbine-only TS unit, the remote‑cup TSR, or the full cart-mounted TSP with pressure pot and compressor, the ProFinish line adapts to different job sizes and requirements.

- Comprehensive parts & accessory support — With parts like the Pressure Pot Assembly, Compressor Assembly, Quart Cup Assembly, and Cart Assembly, users can build or maintain a complete HVLP spray setup with genuine OEM components, ensuring compatibility and durability.

Applications

The ProFinish TS / TSR / TSP systems are ideal for:

- Interior and exterior painting where a smooth, even finish is needed (e.g. cabinets, doors, furniture, trim).

- Medium‑to‑large projects where remote cup or pressure pot capacity removes frequent refilling, improving efficiency.

- Jobs requiring mobility and flexibility: the cart setup (TSP) is well‑suited for contractors moving between sites.

- Situations where robustness, reliability, and easy maintenance matter — because all major assemblies and parts are standardized and replaceable.

FAQ’s

Q1: What’s the difference between Pro-Finish TS, TSR, and TSP?

- The base TS turbine is the core HVLP unit.

- TSR adds a 2‑quart remote cup + compressor system, giving more material capacity and flexibility.

TSP integrates turbine, pressure pot, compressor, and cart assembly — ideal for larger jobs or when you want a pressure‑feed setup with easy mobility.

Q2: Can I mix and match assemblies (e.g. use the Pressure Pot Assembly with the TS turbine)?

Yes , the modular design lets you upgrade from a simple turbine to a full-pressure feed system by adding components like the Pressure Pot Assembly (770‑565) or the Cart Assembly.

Q3: How do I know when to clean or replace the filters in the turbine?

The turbine uses air filters for proper atomizing and cooling air. If you notice reduced airflow, overheating, or a warning light (if equipped), you should clean or replace the filters. Regular daily inspection is recommended.

Q4: Is the system suitable for a variety of coatings (thin and thick)?

Yes. By adjusting fluid/air needle‑nozzle combinations and using remote‑cup or pressure‑pot assemblies, you can spray light finishes as well as heavier coatings.

Q5: What maintenance steps are important for longevity and consistent performance?

Clean air filters daily, flush and clean the spray gun and fluid paths after each use, inspect hoses and seals, and use genuine replacement parts (e.g. OEM assemblies) when servicing — this keeps performance reliable and prolongs the equipment’s life.