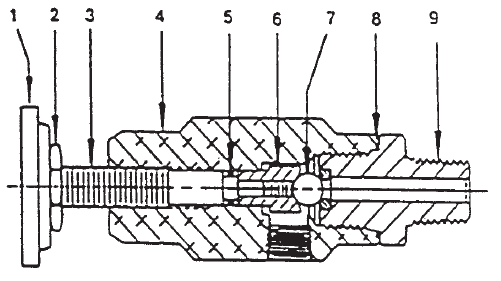

PowrTwin 4500 Bleed Valve Assembly Parts

When you need to maintain or repair your PowrTwin 4500 sprayer’s fluid system, the bleed valve assembly is one of the most critical components. This category covers all genuine Titan‑specified bleed valve parts, from knobs and valve stems to O‑rings and tungsten‑seat valve seats, to help you restore proper pressure release, safe priming, and reliable operation of your unit.

Key parts available in this category

These parts are essential to keep your bleed valve functioning properly, ensuring safe pressure relief, efficient priming, and preventing leaks or pressure loss during operation.

Why Bleed Valve Assembly Parts Matter

- Safety and pressure control — The bleed valve provides a safe way to relieve pressure from the fluid system before maintenance or shutdown, preventing accidental fluid discharge. The official manual for the PowrTwin 4500 lists proper bleed valve operation as essential for maintenance and troubleshooting.

- Maintain pump health & performance — A well‑sealing bleed valve prevents air entrance and fluid leakage. Worn stems, gaskets, or seats can allow air into the fluid path, causing cavitation, inconsistent spray, or pump damage.

- Reliable priming and purge — During start‑up or cleaning, the bleed valve allows trapped air or old material to be purged for smooth fluid flow and stable pressure.

- Simplified maintenance & part replacement — Having access to individual components (knob, O‑rings, stem stop, seat, gasket) lets you replace just what’s worn, more cost‑efficient than replacing the full fluid section or pump.

Maintenance & Usage Tips

- Always relieve pressure using the bleed valve before servicing the fluid section or opening any hose connections, which helps prevent injection injury or spills. Manual for PowrTwin 4500 lists bleed‑valve use in its safety guidelines.

- Inspect the O‑ring (944‑004) and valve seat (944‑904) for wear or damage whenever you perform a service — small leaks often trace back to worn seals.

- If the bleed valve feels loose, leaks fluid, or doesn’t fully close, replace the stem stop (944‑026) or knob (944‑024) to restore proper valve operation.

- Use only Titan‑specified parts — these are rated for the high‑pressure conditions of PowrTwin 4500; substituting generic parts may compromise safety or void warranty.

- Keep a maintenance log with dates and part numbers replaced, which helps track service intervals and anticipate when the next replacement may be needed.

FAQs

What components are included in the PowrTwin 4500 bleed valve parts category?

This category includes the bleed‑valve knob (944‑024), PTFE O‑ring (944‑004), valve stem stop (944‑026), copper gasket (945‑003), and tungsten valve seat (944‑904), all essential for reliable bleed‑valve function and high‑pressure sealing.

How do I know if the bleed valve on my PowrTwin 4500 needs servicing or parts replacement?

Signs include fluid leaking around the valve, difficulty opening or closing the valve knob, pressure not being relieved properly when bleeding, or inconsistent spray pressure, indicating a worn seat, gasket, or stem.

Can I replace just one component of the bleed valve, or do I need to replace the entire valve assembly?

Yes, often replacing individual worn parts (like the O‑ring, stem stop, or seat) is sufficient. You don’t need to replace the whole assembly unless multiple components are damaged.

Why is it important to use genuine Titan bleed valve parts for PowrTwin 4500?

Genuine Titan parts are rated for the high pressures and fluid conditions native to the PowrTwin 4500. Using non‑specified parts may lead to leaks, pressure loss, or unsafe operation under spray pressure.

How should I maintain and inspect the bleed valve on my PowrTwin 4500 for longevity?

Regularly check for leaks, inspect the seal (O‑ring) and valve seat, ensure the knob and stem move smoothly, and whenever you flush or clean the system, always bleed pressure before maintenance. Replace worn parts at the first sign of wear.