Subcategories

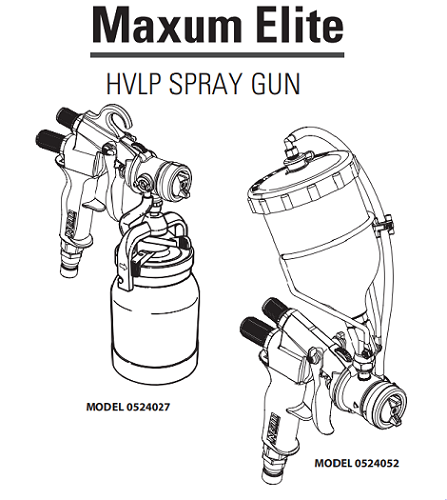

NEW PRODUCTS FOR FEBRUARY - MAXUM ELITE HVLP SPRAY GUN

For professional painters who need accuracy, control, and efficiency, the Maxum Elite HVLP Spray Gun is an excellent tool. Superior atomization from this high-volume, low-pressure (HVLP) spray gun guarantees a smooth, even finish with little overspray. The Maxum Elite maximizes paint transfer efficiency while producing outstanding results whether you're working on carpentry, automobile painting, or fine finishing.

You must have access to the Maxum Elite HVLP Spray Gun Parts List in order to keep your spray gun operating at peak efficiency. In order to guarantee that your spray gun runs as efficiently as possible, this list covers essential parts including nozzles, air caps, filters, and seals. The Top Feed Cup Assembly (P/N 0524045) is one of the essential parts that enables effective paint flow and ideal spraying performance.

Go to AllTitanParts.com to find authentic replacement parts and accessories. Our comprehensive Maxum Elite HVLP Spray Gun Parts List guarantees that you will be able to locate genuine, high-quality parts for upkeep and repairs. To maintain your Maxum Elite HVLP Spray Gun in optimal condition for all of your professional painting requirements, browse our assortment right now!

The Maxum II Compressor Regulator Cup Gun (0508062) is a reliable, high-performance spray gun designed for professional and DIY paint applications. Engineered for precise control and consistent results, this regulator cup gun attaches seamlessly to air compressors and is optimized to deliver smooth spray patterns with minimal overspray. Its sturdy build ensures durability and long service life, making it an ideal tool for automotive finishes, furniture refinishing, cabinetry work, and general surface coatings.

The included regulator on the gun allows painters to adjust air pressure directly at the tool, improving efficiency and accuracy without the need to reach back to the compressor. Its ergonomic design and balanced weight reduce fatigue during prolonged use, while its easy-to-service components ensure maintenance and replacement of wear parts can be done quickly.

The Maxum II Compressor Regulator Cup Gun (0508062) is used in a range of painting and finishing tasks, including:

The Material Flow Adjustment Knob controls the rate at which paint or coating exits the gun. Turning the knob increases or decreases material flow, allowing you to fine-tune the spray output for different coatings or finish requirements.

Regular inspection is recommended every 25–50 hours of spraying or when air leakage is noticeable. Over time, the seal can wear, leading to inefficient air control. Replacing it when damaged helps maintain optimal atomization and pressure control.

The Needle Spring ensures consistent movement of the needle valve that controls paint flow. If the spring weakens or breaks, inconsistent paint flow and sputtering can occur. Replacing a worn Needle Spring restores responsive trigger action and smooth material delivery.

The Air Valve Spring returns the air valve to its closed position after each spray. This helps maintain a steady supply of air and prevents continuous airflow when the trigger isn’t engaged. A strong, undamaged spring ensures proper air control and efficient compressor use.

Absolutely. Worn internal components can lead to inconsistent airflow, poor atomization, sputtering, irregular spray patterns, or difficulty in controlling material output. Replacing these wear parts helps keep the spray gun operating at peak performance.