Subcategories

NEW PRODUCTS FOR FEBRUARY - EPIC GAS SPRAYER PARTS

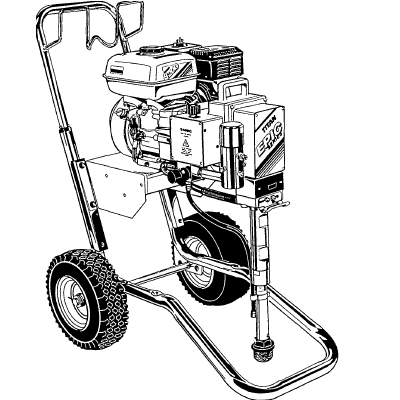

Epic Gas Sprayers are built for contractors who need powerful, uninterrupted spraying performance in tough environments. To keep these machines running at their best, high-quality replacement parts play a critical role. The Epic Gas Sprayer Parts bring together essential components designed for long-term durability, accurate spray delivery, and maximum productivity on every job site.

Whether you operate the Epic 690HPG, Epic 690GX, or Epic 1200HPG, this category ensures you have access to every part required to maintain pump strength, preserve spray consistency, and extend the life of your gas sprayer. These parts are built with high-grade materials and engineered to withstand heavy coatings, high-pressure output, and continuous-duty operation.

Epic Gas Sprayer Parts are ideal for contractors and professionals working in:

Each part is listed by compatible model numbers such as Epic 690HPG, Epic 690GX, and Epic 1200HPG. Always match your sprayer model with the product description to ensure proper fit.

Loss of pressure may occur if the inlet valve, outlet valve, or filter screens are worn or clogged. Inspect these components, as they often need service alongside packings for full pressure recovery.

Filters should be checked daily and replaced when they show signs of clogging or coating buildup. Regular filter maintenance protects the pump and ensures steady spray flow.

Yes. A worn piston rod can cause poor sealing inside the pump, leading to reduced pressure, inconsistent spray patterns, and more strain on the motor. Replacing the rod restores full pump performance.

Verify that the inlet valve is correctly installed, the siphon hose is airtight, and the return hose is free from cracks. Air leaks or blockages in these areas commonly cause priming failures.