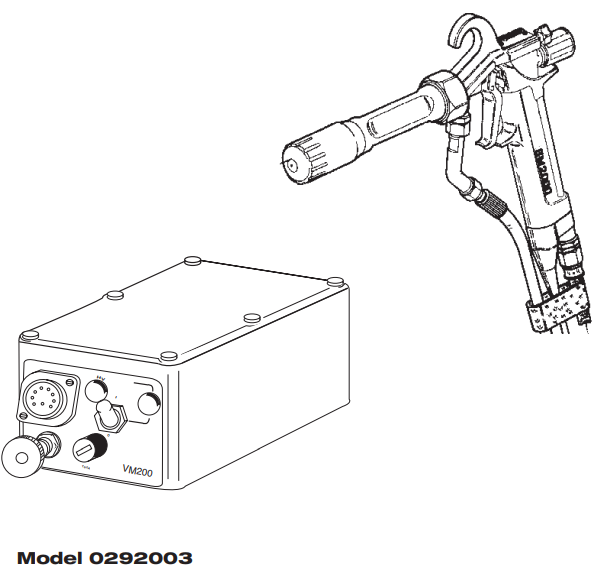

Titan Stati‑Kit 2000 Electrostatic Spraying System

Upgrade your finishing process with the Titan Stati‑Kit 2000 electrostatic spraying system — a complete solution designed for high‑performance coating applications where precision, uniformity and efficiency matter. Whether you’re coating large surfaces, industrial equipment or detailed assemblies, this system offers the technology and parts you need to deliver top results.

Why Choose the Titan Stati‑Kit 2000 System

- Built specifically for electrostatic spraying, ensuring optimal charge, atomisation and adhesion for coatings on complex surfaces.

- Genuine parts and accessories for the Stati‑Kit 2000 guarantee compatibility, correct performance and long service life.

- Using the right system and components reduces overspray, improves coverage uniformity and can lower material costs and rework.

- All listed sub‐categories (system parts, accessories, spare tips) let you find everything you need in one place — from main modules to expendables.

- Backed by expert support and documentation — you get the precision of electrostatic performance backed by trusted components.

How to Choose the Right Components for Your Stati‑Kit 2000

Here are a few guidelines to help you select the correct parts or accessories:

- Start with system condition: If your unit’s performance has degraded (weaker charge, uneven coverage, atomisation issues), begin with the “Parts Listing” sub‐category to check modules, power supplies, hoses and core assemblies.

- Assess your application: If you need to optimise for a specific job (e.g., high‑volume runs, tighter tolerance finishing, or switching materials), check the “Accessories” sub‑category to see adaptors, control modules or extension kits.

- Check nozzle/tip wear: In electrostatic systems, tip wear or damage can degrade finish quality. Visit the “Spare Tips” sub‐category — selecting the correct size and style ensures consistent electrostatic charge and spray pattern.

- Confirm compatibility: Always ensure that any component (tip, accessory, module) is listed for the Stati‑Kit 2000 system — mismatched parts may affect performance or safety.

- Plan maintenance proactively: Electrostatic systems require clean feeds, correct grounding, proper tip condition and correct voltage/grounding setups — check parts periodically and replace before job‑critical failure.

FAQs

1. What sub‐categories are included with the Stati‑Kit 2000 spraying system parts?

The parts listing covers three main sub‐categories: the core “Parts Listing” of system components, the “Accessories” section for add‑ons, and the “Spare Tips” section for nozzles and spray tips designed for electrostatic finishing.

2. How do I know if I need to replace parts from the “Parts Listing” sub‐category?

If your system shows reduced charging performance, inconsistent spray patterns, increased overspray or fouling of components, it likely needs replacement of core system parts (power modules, hoses, control modules) found in the “Parts Listing” sub‐category.

3. Can I just buy accessories to modify my existing Stati‑Kit 2000 system?

Yes, if your main unit is functioning well but you want to adapt to a new job type (different material, larger volume, different environment), the “Accessories” sub‐category provides add‑ons and conversion modules to tailor your system.

4. Why are “Spare Tips” important for the Stati‑Kit 2000 system?

In electrostatic spraying, the spray tip or nozzle has a direct influence on atomisation, charge transfer and finish quality. Worn or damaged tips can reduce coating efficiency, cause poor adhesion or uneven coverage — replacing them from the “Spare Tips” sub‐category ensures optimal performance.

5. How often should I inspect parts in the Stati‑Kit 2000 system and replace tips or accessories?

Inspection frequency depends on usage, material type and job demands. As a rule:

- Check core system parts (power modules, hoses) every major job or quarterly.

- Inspect accessories when changing job types or when performance shifts.

- Replace spray tips whenever you see wear, pattern degradation or suspect charge loss, typically after heavy use or when switching to different coatings.