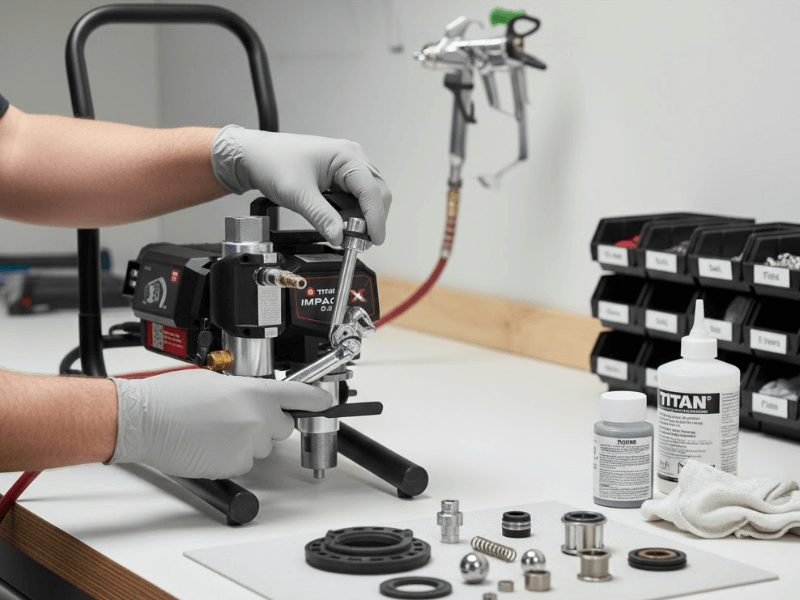

When you are starting to work with sprayers, you do not think of how maintaining the sprayer parts is just as crucial as maintaining the sprayer. If you do not take care of the sprayer parts as they should be taken care of, you’re going to lose them really early. You have to make sure that each part of the sprayer is checked regularly so it does not break down. There are different Titan impact X sprayers, like 410, 440, 540i, and 640, that come with various parts that need full attention.

When you’re neglecting taking care of the sprayer parts automatically means that it is going to cost you a lot in the future. For example, if the part breaks down completely, you have to get a new one, which costs a lot of money. On the contrary side, if you are focused on maintenance, you do not have issues, and your downtime will also be decreased. Also, when the parts are not maintained thoroughly, it automatically means that the efficiency will be highly impacted, and you have to be careful about this.

When we talk about impact X sprayers, we have to mention how each sprayer and its parts have different challenges. We are going to talk about the challenges below, so you know what you need to focus on whenever you are using those particular sprayer parts.

When it comes to the impact X 410 sprayer, we have to mention how it does not require a lot of maintenance, but the parts are really prone to wear. This means that the contractors have to be really careful and have to keep checking whether the hose and seal are working properly or not. As soon as you detect that the hose or the seals are starting to wear out, you should immediately get them replaced.

For the 440 sprayer parts, we have to mention how the pump and seal need a routine check. These parts of this sprayer are prone to getting damaged a lot because of overuse. This sprayer specifically is used for heavy work, and that is exactly why it needs a lot more focus than any other sprayer. When you pay attention to these parts, your sprayer and the parts are going to last you a long time.

Talking about the 540i sprayer parts, we have to discuss how they require mechanical and electronic maintenance. It comes with digital control, so the most common damage is associated with it. Apart from checking all the parts present in the sprayer, you have to make sure you are also checking the pressure calibration and digital control to make sure they are working just fine.

Each of the sprayers and its parts comes with various issues, and so you have to understand each one properly to find the problems and deal with them. When you are well aware of which part is most likely to get damaged in each sprayer, you can get rid of the problem accordingly.

If we are talking about spray parts, people often ask why Titan Impact X Parts Maintenance is important. Well, it is not just specified to the impact X sprayer parts but to all the other ones as well. It does not matter which product you are using if you do not maintain it in a proper way it is going to get damaged really soon. You have to pay attention to the regular maintenance to make sure that all your money turns out to be worth it.

Talking about the maintenance is essential because it automatically increases the lifespan of your sprayer parts. Not only that, but you will also be able to get maximum efficiency on the job site, and the parts will not end up breaking down. If you do not want to spend money every now and then on getting sprayer parts, then again, you have to make sure that you maintain them properly. Especially for the contractors who use these sprayers and parts for heavy work you should always know that natural wear and tear is a must. If you do not keep a check on these sprayer parts, you will have to purchase new ones every now and then.

There are many factors that affect the performance of the sprayer parts. We are going to discuss some of these factors so you can be well-informed. This way, you will know where you need to be careful to get maximum performance from your sprayer parts.

There are many little things that you really have to pay attention to whenever you are working with sprayer parts. Small steps like storing them and cleaning them can save you not just money but a lot of your time. you will not have to spend hours cleaning them when you open them after weeks if you regularly maintain them.

When it comes to sprayer parts, each prayer has different parts and different problems. But there are some problems for each prayer that are really common that you need to understand before using them. We are going to talk about each one of these problems so you know what you need to see whenever your sprayer starts acting up.

The first common problem that comes up is the loss of pressure in the Impact X 410 sprayer. Whenever you are going through this problem, know that it can easily be because of the clogged filters or filter parts. There are two main filter points that include the intake filter and the manifold filter.

How To Identify

If you think that your motor is sounding a little weird and there is absolutely no material coming out of it, then it is a sign that the filters are completely clogged.

Solution

The solution is really easy because all you have to do is take the filters out and see if they are damaged or not. If the filters are not completely damaged, you can easily clean them and get rid of the issue right away.

The pressure loss also happens in the impact X440 sprayer, and for that, you have to make sure to check the packing and seals. The pressure loss often happens when the packing and the seals are worn out in the 440 sprayer.

It is obvious that the packing, seals are completely worn out if you are cleaning the filters and you are not seeing any impact because the problem is not going away. You will be able to see material leaking constantly. The motor will also not be able to work properly.

For this problem, it is quite obvious that you will have to make sure that you replace the packing and seals. There will definitely be no other way to go about it because the parts that are fully damaged automatically need a replacement.

Titan Impact 540I Sprayer Parts Maintenance

Coming to the third sprayer, which is the impact X 540i Sprayer, know that there are also pressure fluctuations that people face while using it. Coming to the problem, it can often be because of the faulty digital valve that is present in this sprayer.

It is really easy to identify in this sprayer because the pressure fluctuations are quite obvious. You will see that the pressure will constantly be jumping from an extremely high to an extremely low point. You will have to check the pressure transducer as well as the digital wall to make sure there is no fault within them.

You will have to check for any error codes in this sprayer because it comes with a digital display. It will definitely be easy to identify through this, and then you can get it fixed from a professional.

Leaking issues are again really common in these parts. The most common point for leakage is the O-rings, seals, and hoses. These parts are found in fittings, internal fluid pumps, and gun swivel connections.

The most common reason for this is that the parts have aged so much. Alongside that it can also be because you have not changed them for a long time. It can be because of the over-tightening of the parts. You need to check that to make sure this is not happening. You should always replace the faulty parts to make sure the leaking stops and you can work easily on the job.

This issue is the most common one in the 410 hoses because they are built with light materials, and so they can get heavily impacted.

If you’re facing spray pattern problems and you are not getting a proper one, then you should always check the tips. It often happens because the tips are worn out, or there are also gun blockages that are not letting the spray flow properly. You should always check these parts to ensure that they are working just right.

If you’re going through this issue, you have to make sure that you replace the tip because there is no fixing it. You will have to purchase a new one to make sure that you can immediately get rid of this problem.

People are wondering what the signs are that you need to focus on DIY solutions or purchase new ones.

There are some simple things that you have to understand: if the parts, like filters, get impacted, you can easily get rid of the issue by cleaning them. But if the problem occurs with O-ring, seals, packing, or tips, you need to replace them because they cannot be worked out with maintenance. For this, you have to really understand each of the sprayer parts to know what needs to be done whenever you are facing an issue with any particular part.

We know that you are scared of focusing on the maintenance because it definitely does take a lot of time. But you also have to understand that if you’re not paying attention right on time, you can end up regretting it so much. There are some simple preventive maintenance practices that you can opt for whenever you are working with a sprayer. If you focus on these things, you will be able to easily maintain your sprayer's performance and condition without any hassle. Let’s dive right in without any delay. Through this you will find out what you can do to maintain your sprayers properly.

.

Winter is approaching really quickly. All the people who have sprayers should know that they have to use antifreeze fluid to make sure the sprayer works just fine. It will help save all the sprayer parts in your sprayer. You will also not have to purchase new ones after the season passes.

You should also always make sure to get tools and maintenance kits from Titan so that you are fully taking care of your sprayers and them. All the products are available on our website, which you can visit and purchase according to what you’re really looking forward to getting.

When it comes to sprayer parts maintenance, there is no specific timeline because you have to do different things at different times. There are some specific maintenance tasks, for example, some things that you have to do daily, some that you have to do weekly, and some that are on a monthly basis. You should check the filters and clogging every day, and you should focus on cleaning your spray guns weekly. The overall maintenance should definitely be opted for at least once a month to make sure the performance is not decreased.

Not checking the sprayer parts regularly is one of the most common mistakes that people make when it comes to 440 spray parts. People think that it is a simple sprayer and it does not require a lot of attention, and that is exactly where they lack. You should not do this, and always make sure that you are checking the parts at least once a week. This will ensure they are properly maintained and they do not end up getting damaged completely.

The 540 parts do require different maintenance than the 540 parts because they come with a proper digital display that requires a different type of attention. You should make sure that you are going through the maintenance guy to make sure that you are taking care of the sprayer parts in a proper way. Always ask professionals for guidance if you do not know what to do.

No, DIY maintenance is not going to void your warranty, and you should always keep a check on your spare parts to make sure that you are maintaining them properly. It will become really easy for you to maintain your sprayer if you check it on a regular basis.

If you are getting into spraying, then you have to understand the importance of maintaining the sprayers and the parts. It is not just a job where you have to pick up your sprayer and do the painting because there is a lot that goes on between. Each of the sprayer parts requires a lot of attention, and you should know that beforehand. You have to focus on regular maintenance and keeping a check on everything so that it increases the lifespan of your sprayer parts. When you are maintaining your sprayers and their parts, it is obvious that you will be able to get better results as well. If these sprayer parts are damaged, the patterns will be irregular, and the quality will also be low; if you do not want that, you should definitely pay attention to maintaining the parts.

That being said, if you're looking for genuine sprayer parts that you’re not able to find anywhere else, then you should not look any further and connect with us at AllTitanParts. We are sure that you are only going to get the best quality parts from us, and you can use them for as long as you want if you properly maintain them. You can visit us any time you want, get in touch with our team, and order your sprayer parts, and we will make sure we deliver them to your doorstep.