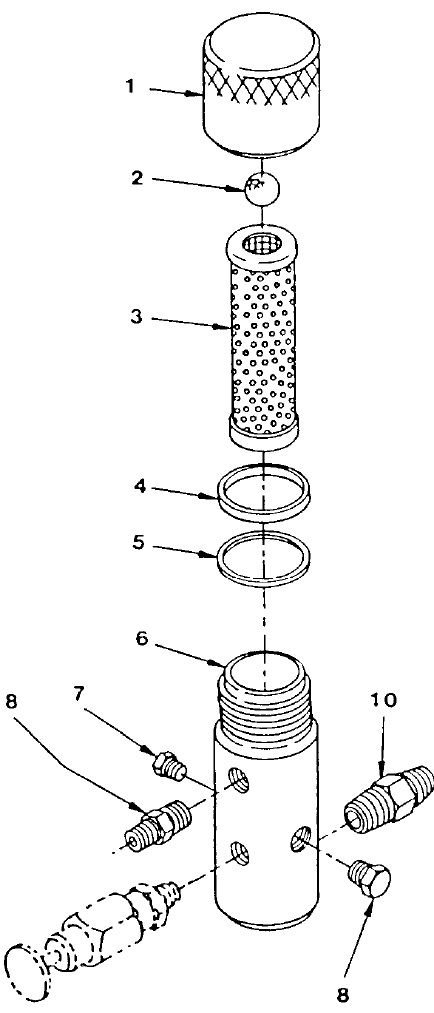

PowrTwin 4500 Outlet Manifold Filter Assembly Parts

When maintaining your PowrTwin 4500 airless sprayer, the outlet manifold filter assembly plays a critical role in protecting the fluid path, ensuring clean sprayed material, and safeguarding gun tips from debris. This category is dedicated to genuine filter and manifold‑filter‑assembly components made to fit the 4500’s fluid system. Use these parts to keep spray performance reliable, spray output clean, and system longevity intact.

Why this category matters

- Protects pump and spray output: The manifold filter captures contaminants and particles before fluid reaches the spray gun, preventing clogs, tip failures, or damage downstream.

- Ensures stable pressure and flow: A properly maintained outlet filter assembly helps maintain consistent pressure and fluid flow, critical for achieving smooth, even coats on surfaces.

- Extends sprayer lifespan: By filtering out debris and protecting internal components, the filter assembly reduces wear on the pump and valves, which extends service life and reduces maintenance costs.

- Simplifies maintenance: Having dedicated manifold‑filter assembly parts means you can replace only the worn elements (filter, gasket, seat, etc.) instead of entire fluid blocks, saving time and parts cost.

Typical parts you’d expect in this category

Depending on your inventory and exact model build, these are the kinds of parts that belong under Outlet Manifold Filter Assembly Parts for a PowrTwin‑series sprayer. Be sure to match part numbers from your internal catalog. Example items include:

- Filter element / manifold filter (various mesh sizes) — a replaceable mesh filter to trap paint particles and debris before fluid leaves the manifold.

- Filter housing or filter body / manifold block — the structure that contains the filter element and connects to the pump outlet.

- Gasket / PTFE seal for filter housing — ensures a leak‑free seal between filter housing and manifold body or cap.

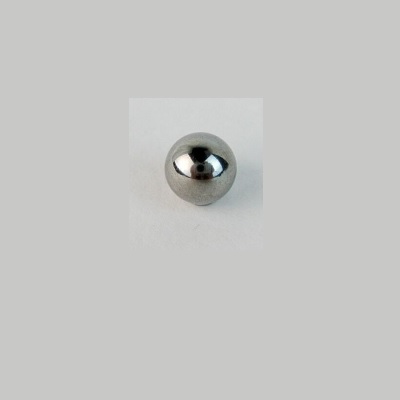

- Filter cap/cover assembly (with spring or check‑ball if applicable) — secures the filter element inside the housing; may include spring or ball‑valve check depending on design.

- Check‑valve / outlet valve seat/sealing components (if manifold uses check‑ball or back‑flow prevention) — in designs where the outlet manifold also regulates flow or prevents back‑flow, those internal valve components belong here.

- O‑rings / O‑ring kits or replacement seals — for any sealing interfaces inside the manifold filter housing or between the filter housing and outlet passages.

Maintenance & installation tips

- Always relieve system pressure before disassembling the outlet manifold filter — this is a high‑pressure fluid segment of the sprayer.

- Inspect filter element periodically — replace mesh filters when you notice pressure drop, spray irregularities, or if the filter screen is clogged or damaged.

- Whenever you open the filter housing, replace gaskets/seals / O‑rings to maintain a tight fluid seal and prevent leaks under pressure.

- If your manifold uses a spring or check‑ball for flow/regulation, inspect those internal components (seat, spring, ball) for wear — replace if worn or damaged to avoid malfunction.

- Use only OEM or OEM‑spec filter assembly parts for manifold repair; aftermarket or incorrect parts may not meet pressure ratings or fit tolerances, risking leaks or failure.

FAQs

-

What parts belong to the outlet manifold filter assembly on a PowrTwin 4500?

The assembly typically includes a replaceable mesh filter element, a filter housing or manifold body, gaskets or PTFE seals, a filter cap or cover, and — if applicable — internal components like check‑ball valves, seats, springs or O‑rings to maintain fluid flow control and sealing.

-

How often should I service or replace the manifold filter in PowrTwin 4500?

It depends on usage and coating materials. As a rule of thumb, inspect the filter after heavy jobs or viscous materials; if you notice a pressure drop, spray inconsistencies, or visible debris buildup, replace the filter element and any worn seals immediately.

-

Can I use generic filters or universal parts for the PowrTwin 4500 manifold?

It’s strongly recommended to use genuine or OEM‑spec parts. The outlet manifold operates under high pressure and requires precise sealing and flow characteristics — wrong or un-rated parts may lead to leaks, performance issues or safety hazards.

-

What happens if the outlet manifold filter is clogged or damaged?

A clogged or damaged filter can cause reduced fluid flow, inconsistent spray pressure, tip clogging at the gun, and potentially increased wear on pump components — risking premature failure or poor finish quality.

-

How do I know if the filter housing or check‑valve components need replacement?

If you observe fluid leaks around the housing, pressure drop even after replacing the filter, unusual spray behavior, or the check valve not sealing properly (back‑flow happening), inspect the filter housing, seal/gasket, valve seat, and internal check components — any wear or damage warrants replacement.