Subcategories

NEW PRODUCTS FOR FEBRUARY - POWRMAX TEXTURE SPRAYER

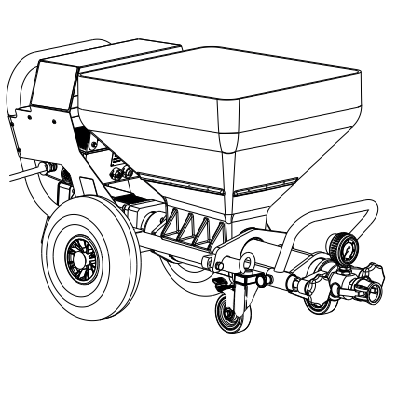

A strong and effective instrument for superior texture and coating applications is the PowrMax Texture Sprayer. Maintaining your sprayer in top condition guarantees seamless operation and expert results whether you're working on home or commercial jobs. We provide a large selection of replacement parts at AllTitanParts.com, such as pressure regulators, hoses, filters, and spray guns. Your sprayer's lifespan can be increased and unplanned malfunctions can be avoided with routine maintenance and prompt part replacements.

For reliable texture application, contractors utilizing the PowrMax 605 Texture Sprayer must maintain key parts such the pump system, spray tips, and motor. Your job may suffer from irregular spray patterns or decreased efficiency due to worn-out parts. High-quality, authentic replacement parts are available at AllTitanParts.com to keep your PowrMax 605 operating smoothly and guarantee dependable performance on every task.

AllTitanParts.com makes it simple to find the appropriate parts for your PowrMax 605 Texture Sprayer. You can easily find and acquire the precise parts you require using our website's smooth purchasing experience. Trust us for all your texture sprayer maintenance needs and keep your equipment performing at its best for years to come.

The PowrMax Texture Sprayer is a versatile and powerful solution for applying textured coatings with precision and ease. Whether you’re working on interior walls, ceilings, decorative finishes, or exterior surfaces, this sprayer is engineered to make your job smoother, faster, and more efficient. Designed for both professional contractors and serious DIY users, the PowrMax combines rugged construction with intuitive operation so you can focus on quality results without frustration.

Built to handle a wide range of texture materials from light to heavy and everything in between, the PowrMax Texture Sprayer ensures even coverage and consistent texture patterns on every pass. It’s a robust machine that respects your time and effort by minimizing downtime and reducing clogging or inconsistent flow. With thoughtful features that support ease of maintenance and dependable performance, this sprayer becomes a trusted companion on every project.

The PowrMax Texture Sprayer promotes steady, uninterrupted material feed. This means fewer clogs, more even coverage, and smoother finishes, even with thicker textures.

Powerful pump action and efficient pressure delivery make this sprayer suitable for a broad range of materials—from standard paint textures to dense stucco and decorative finishes.

Constructed with rugged components and reinforced assemblies, the PowrMax is built to stand up to frequent use, transport, and challenging surface conditions.

Ergonomic handling and intuitive operation help reduce operator fatigue and ensure you stay in control during long spraying sessions.

Built‑in serviceability makes cleaning and servicing the sprayer simpler. Quick access to fluid lines and component areas keeps maintenance fast and hassle‑free.

The PowrMax Texture Sprayer is ideal for a wide range of projects, including:

If material flow becomes uneven or sputters, start by checking the fluid lines and pumps. Clogs or buildup in the suction or delivery hoses can disrupt steady flow and cause inconsistent application.

Clogging often occurs when material dries inside lines or filters. Regular cleaning of the PowrMax 605 Texture Sprayer and ensuring that the suction components are clear before each job will help prevent interruptions.

Seals and packings help maintain pressure and prevent leaks. Over time, they can wear down. Replacing worn seals keeps pressure consistent and prevents material from escaping where it shouldn’t.

Inconsistent texture patterns happen when air enters the fluid path or when the pump or sprayer tip becomes clogged. Regular inspection and cleaning of the pump assembly, filter areas, and spray tips ensures smoother, more uniform finish patterns.

If dripping occurs after priming, inspect the valve components and seals. Worn or damaged valve parts can allow material to continue flowing when it shouldn’t. Replacing these parts restores proper shut‑off function.