Subcategories

NEW PRODUCTS FOR FEBRUARY - SPEEFLO POWRTEX SPRAYER PARTS

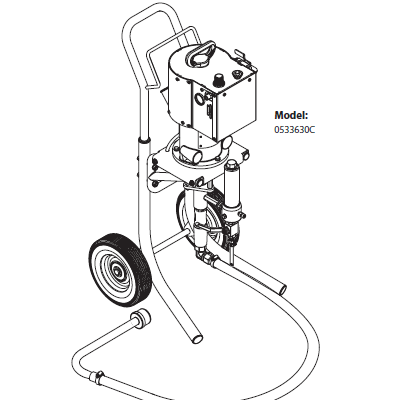

Professionals and contractors need the Speeflo PowrTex Sprayers because they are made for high-performance texture and paint applications. Using high-quality replacement components is essential to maintaining these sprayers' optimal performance. We provide a wide range of parts at AllTitanParts.com, such as pump assemblies, hoses, pressure regulators, and spray tips. Our authentic parts help prolong the life of your sprayer and provide smooth, reliable results, whether you require minor repairs or extensive maintenance.

Maintaining vital parts like filters, valves, and spray guns is crucial for experts utilizing the SPEEFLO PowrTex 300DD / 600DD Texture Sprayers. Wear and tear over time may affect performance, resulting in less efficient or irregular spray patterns. In order to maintain your texture sprayer's optimal performance and guarantee top-notch application for each project, AllTitanParts.com offers sturdy replacement parts.

With its ability to spray paint and texture, the SPEEFLO PowrTex 1200 SF Airless Texture and Paint Sprayer is a strong choice for large-scale projects. Regular maintenance using original parts is essential to extending its lifespan and preserving high efficiency. Your go-to source for dependable replacement parts is AllTitanParts.com, whether you need a new motor, pump system, or pressure control component. With our large selection of premium parts, you can keep your PowrTex sprayer operating at its best.

PowrTex sprayers are reliable and versatile tools designed for applying textured coatings, protective finishes, and specialty coatings in both residential and commercial settings. To keep these machines operating at peak performance, having access to high‑quality PowrTex Sprayer Parts is essential. Whether you’re dealing with worn seals, clogged hoses, or worn‑out pump components, the right parts quickly restore performance and extend the life of your equipment.

1From critical fluid handling components to precision spray valves and durable nozzle assemblies, PowrTex sprayer parts help you maintain consistent material flow and achieve professional‑grade texture sprayer results. These replacement parts are designed to match the rigors of heavy use and provide dependable operation when you need it most—so your projects stay on schedule with excellent outcomes.

PowrTex sprayer parts are essential for a variety of coating applications, including:

Fluid seals and packings in the SPEEFLO PowrTex 300DD / 600DD Texture Sprayers wear over time with regular use. If the sprayer is used frequently, inspect these components on a regular basis and replace them at the first sign of leakage or pressure loss to maintain consistent performance and reliable spray output.

Loss of pressure is commonly caused by worn packings, clogged filters, or damaged valve assemblies. Start by checking the fluid section packings and filters, and replace any worn components.

If the sprayer sputters, spray patterns become uneven, or you notice difficulty switching between spray modes, the spray valve may be worn. Replacing the valve assembly restores smooth flow and consistent performance.

Regular maintenance is essential because hoses on the SPEEFLO PowrTex 1200 SF Airless Texture and Paint Sprayer can crack, clog, or develop leaks over time due to material buildup, high pressure, or frequent bending. Inspect the hoses before each job and replace any worn or damaged hoses to prevent pressure loss, ensure consistent material flow, and maintain optimal spray quality.

Start by cleaning or replacing the filter assembly and checking pump packings and seals. Consistent texture depends on uninterrupted heavy material flow, so removing blockages and replacing worn parts helps restore a smooth finish.