Subcategories

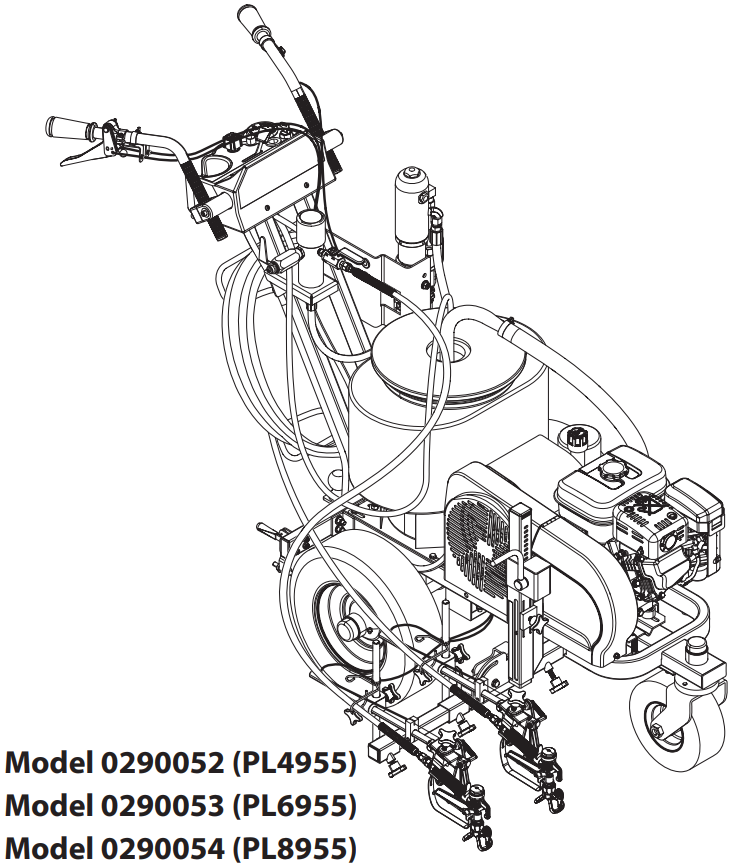

PowrLiner 8955 Main Assembly

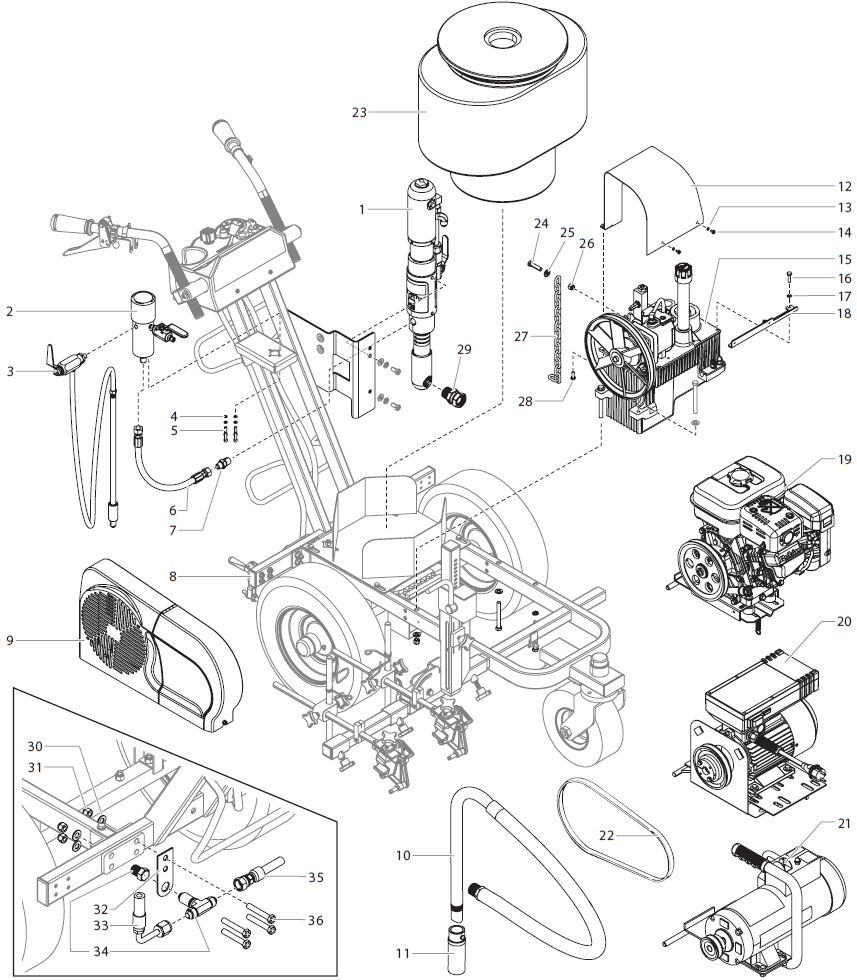

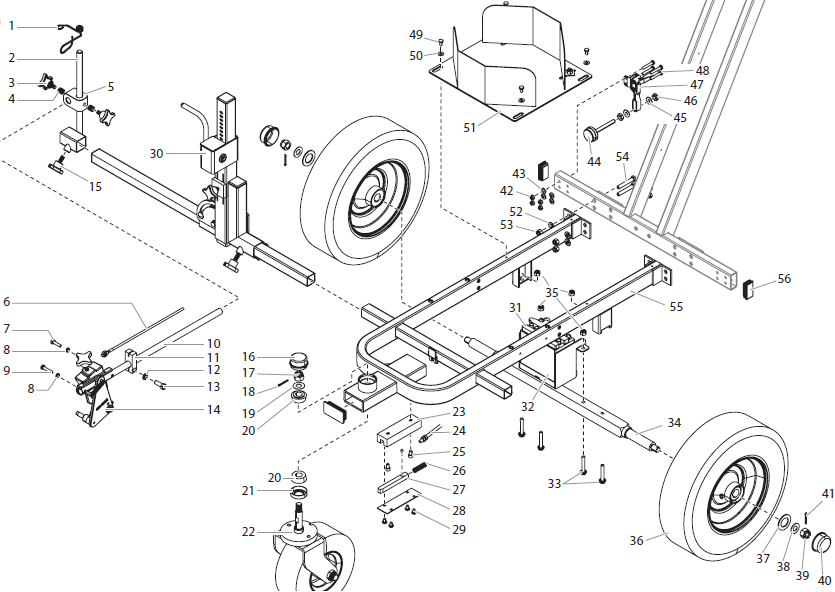

PowrLiner 8955 Cart Assembly I

PowrLiner 8955 Cart Assembly II

PowrLiner 8955 Hydraulic System

PowrLiner 8955 Hydraulic Motor

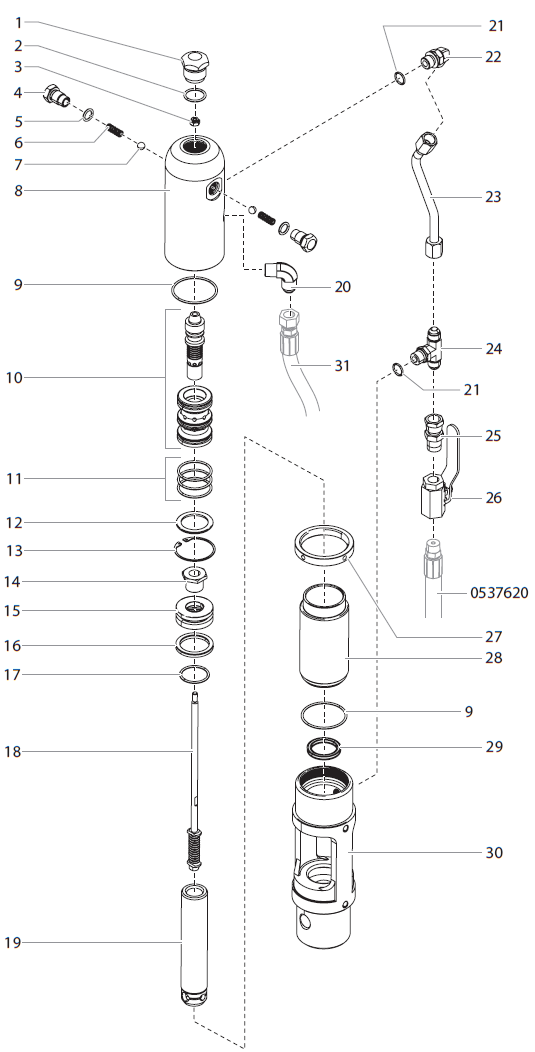

PowrLiner 8955 Fluid Section

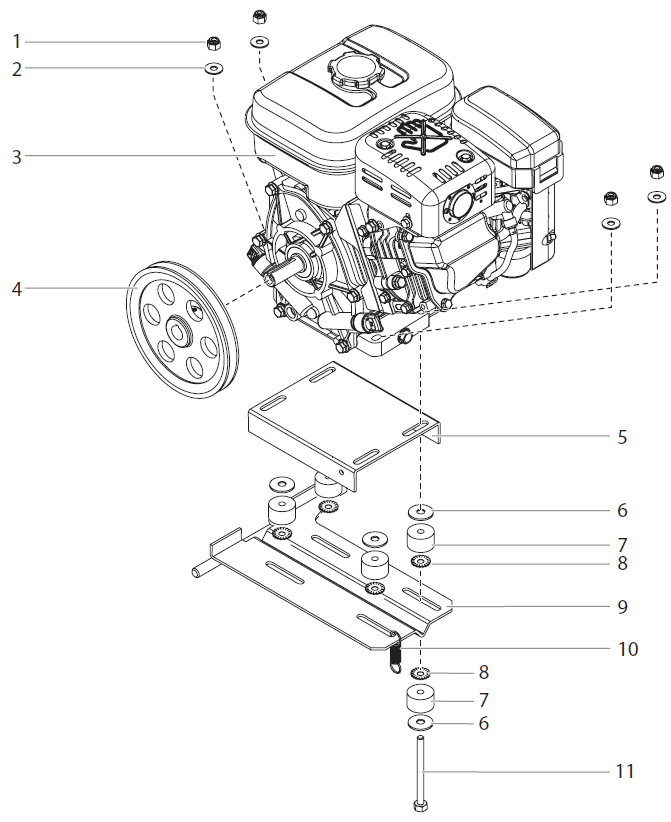

PowrLiner 8955 Gas Convertokit

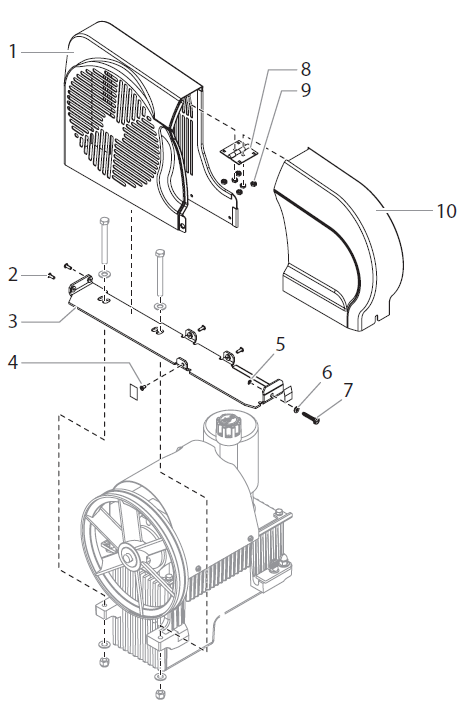

PowrLiner 8955 Belt Guard Assembly

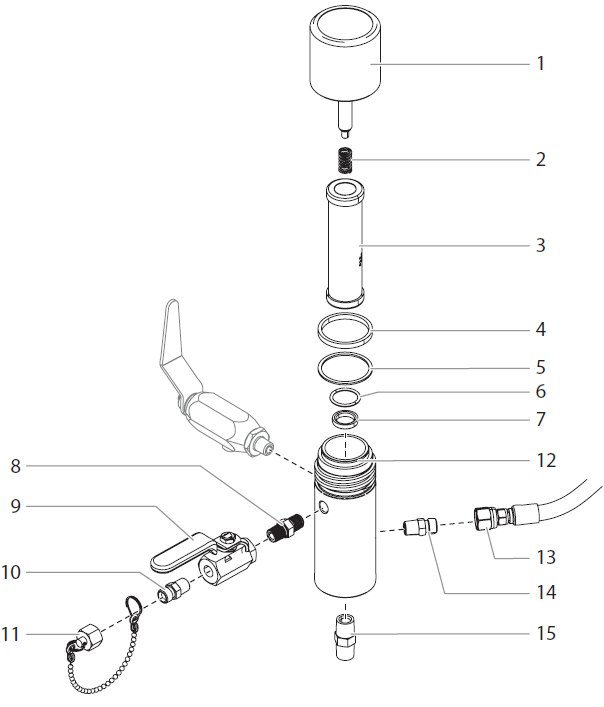

PowrLiner 8955 High Pressure Filter

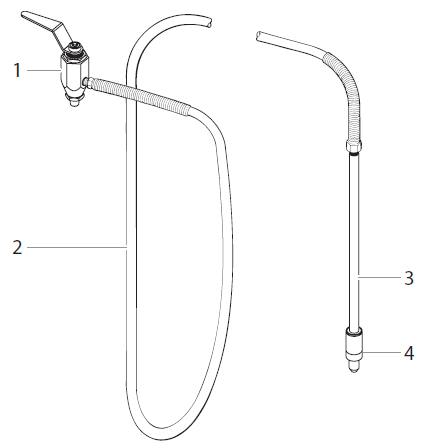

PowrLiner 8955 Bleed Hose Assembly with Valve

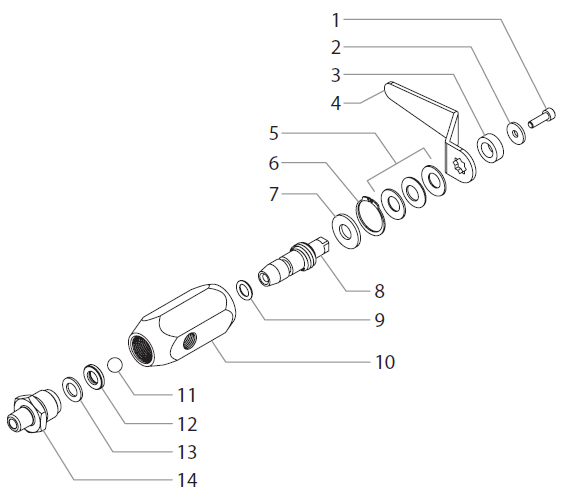

PowrLiner 8955 Bleed Valve Assembly

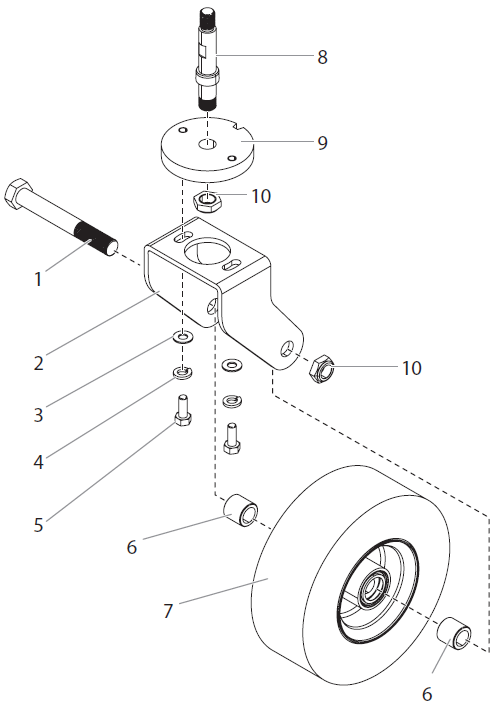

PowrLiner 8955 Caster Assembly

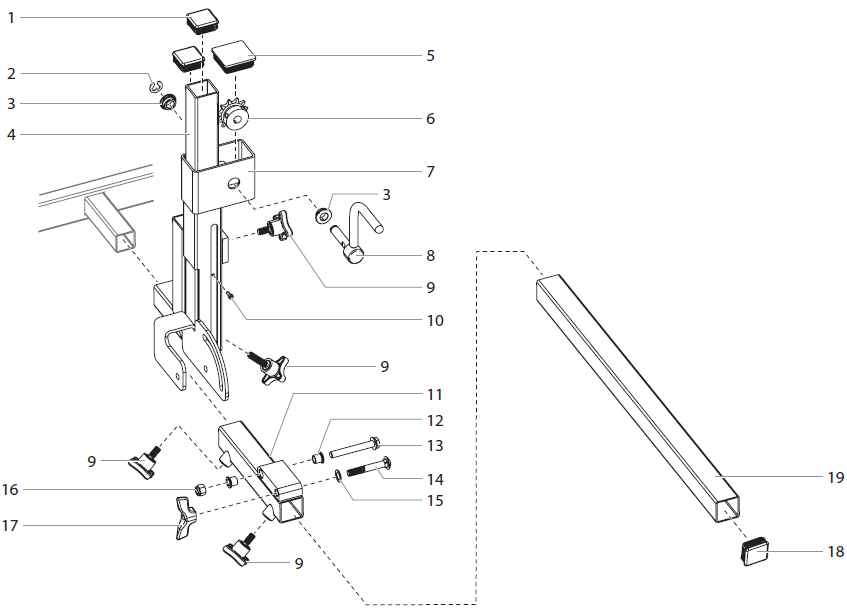

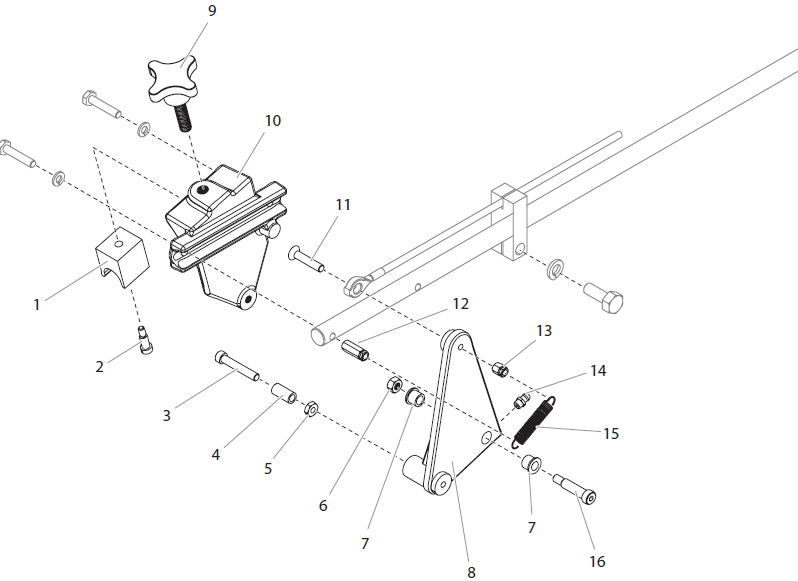

PowrLiner 8955 Lift / tilt assembly

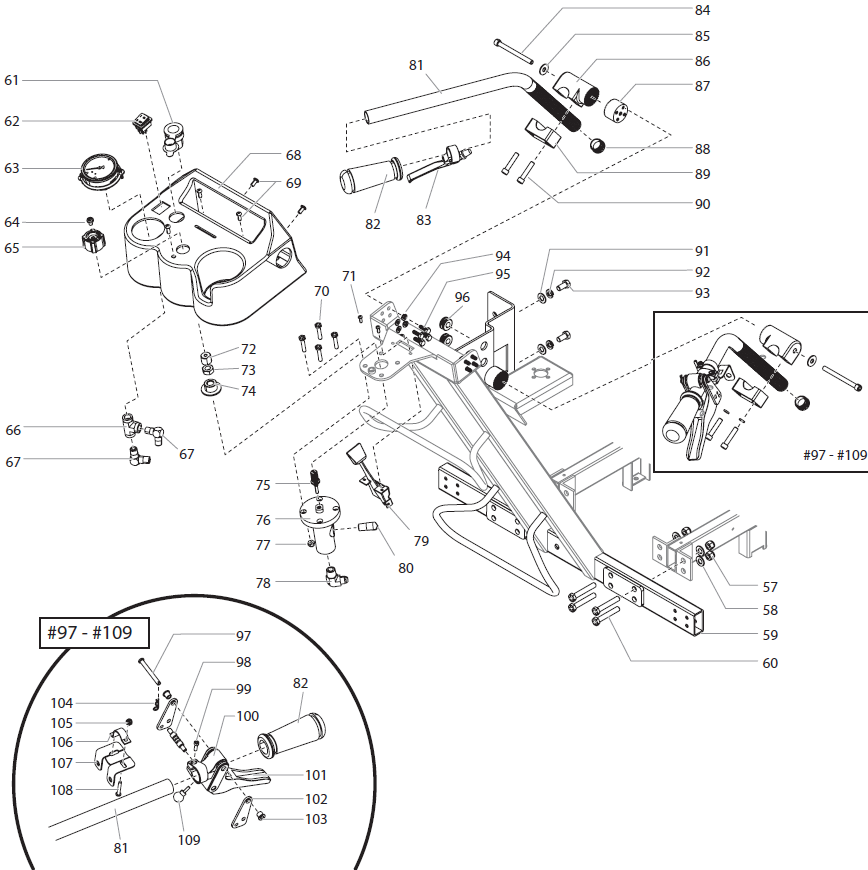

PowrLiner 8955 Gun Holder Assembly

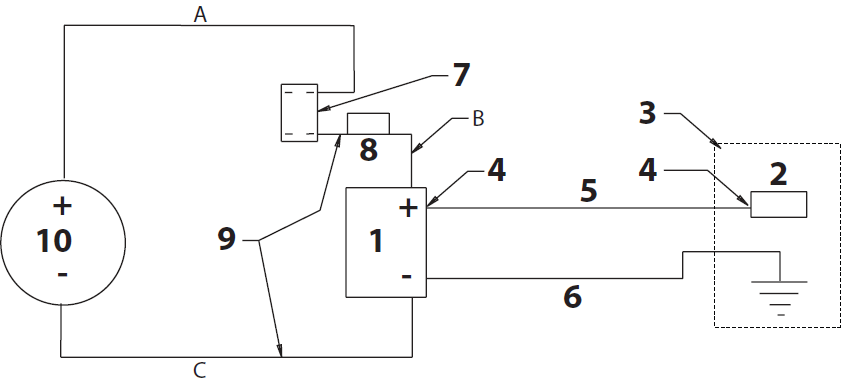

PowrLiner 8955 Connection Diagram

Accessories

NEW PRODUCTS FOR FEBRUARY - POWRLINER 8955

The PowrLiner 8955 is a heavy-duty pavement striping system engineered for professional contractors and facility maintenance teams. Designed to deliver crisp, high-visibility lines with consistent paint flow and reliable performance, the 8955 performs exceptionally well across parking lots, roads, athletic courts, warehouses, and industrial facilities. Built with rugged construction and precision components, this line striping machine balances power, durability, and user-friendly serviceability so you can complete large jobs with speed and accuracy.

The PowrLiner 8955 is designed for professional or high-volume striping work, such as:

You should replace the Fluid Section when you notice pressure loss, inconsistent spray patterns, frequent seal leaks, or excessive wear on packings and pistons. Regular contractors typically inspect or rebuild it every 6–12 months, depending on usage and material type.

Replace the High Pressure Filter if you experience spray pulsation, clogging, paint flow restriction, or debris bypassing the filter. For heavy spraying schedules, it is recommended to replace or clean the filter after every major job.

Yes, if you are converting from electric start to gas-powered operation or replacing a motor with a different fuel configuration. The Convertokit ensures proper mounting, fuel compatibility, and performance safety.

Replace these parts if you notice fluid leakage during priming, difficulty releasing system pressure, cracks in the hose, or valve malfunction. Damaged bleed components can cause pressure buildup and system failure, so they should be replaced immediately.