Subcategories

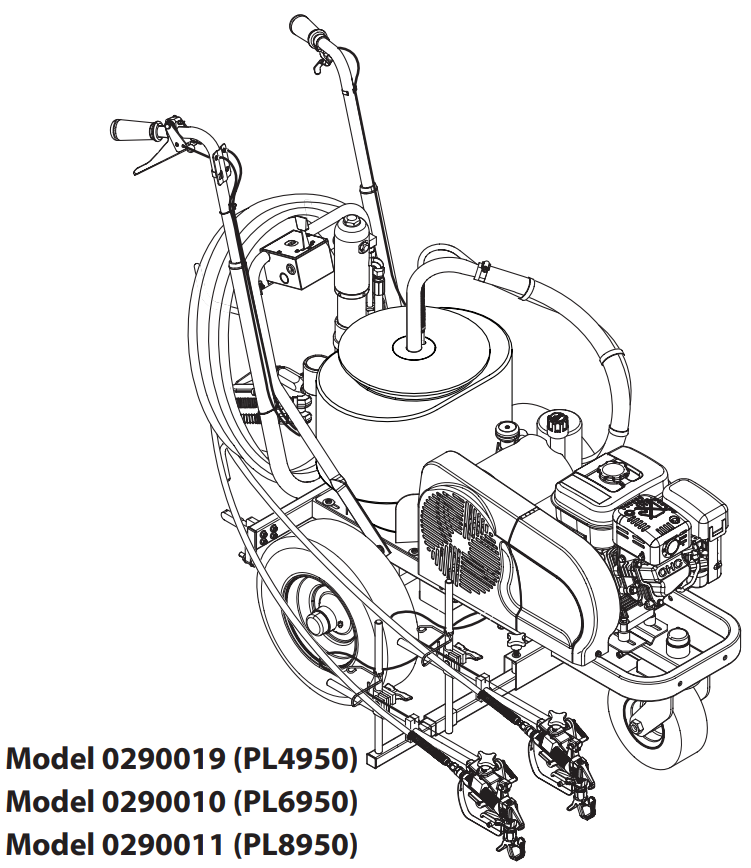

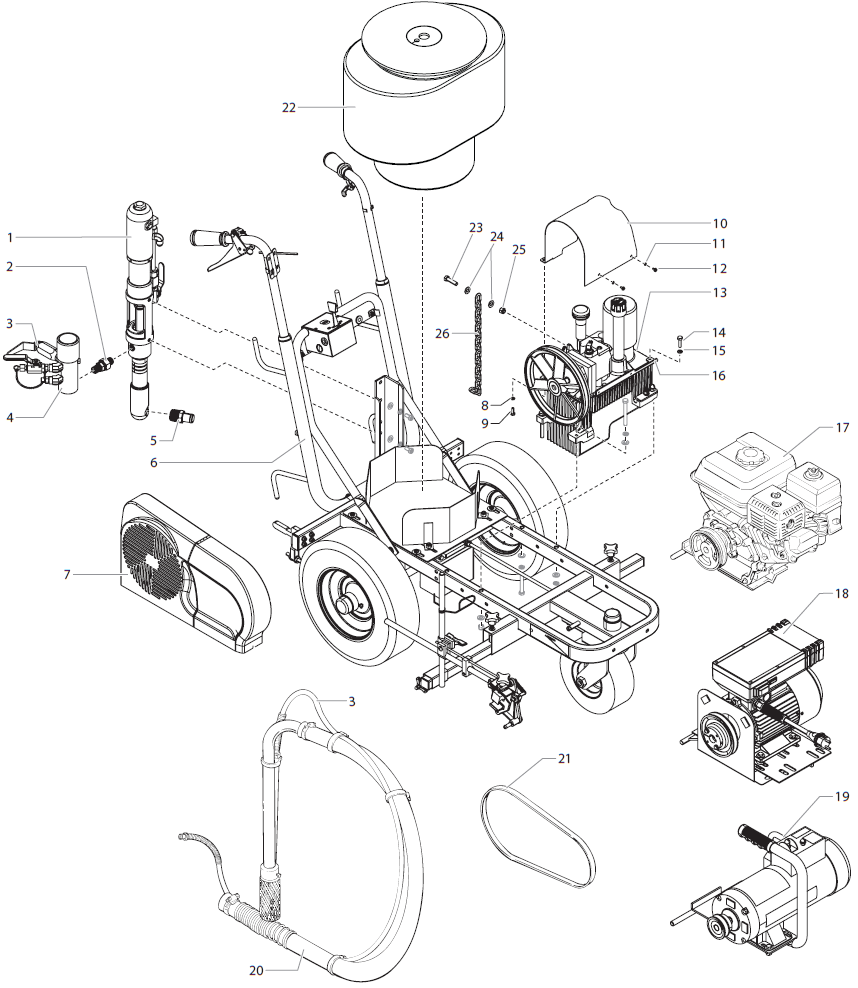

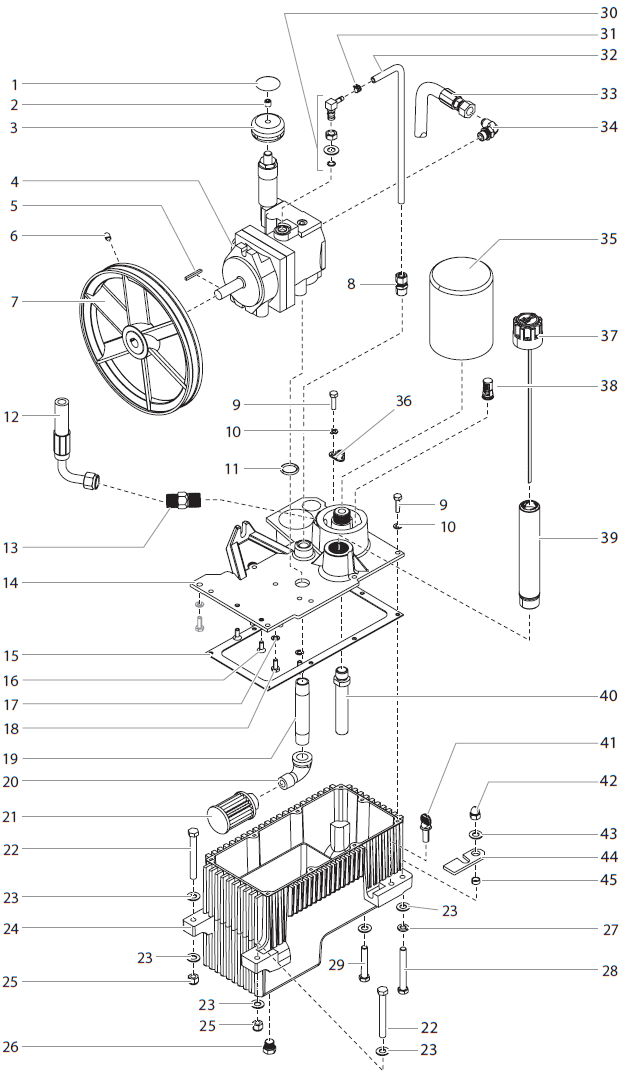

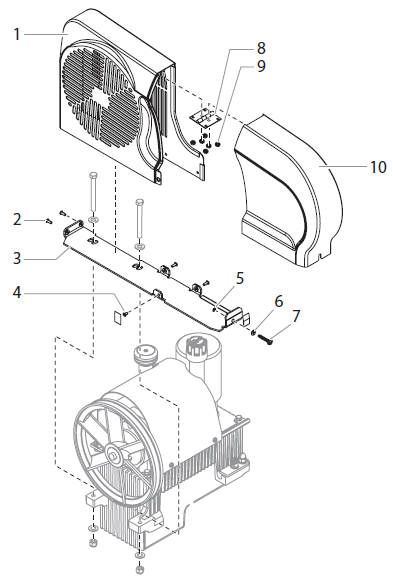

PowrLiner 8950 Main Assembly

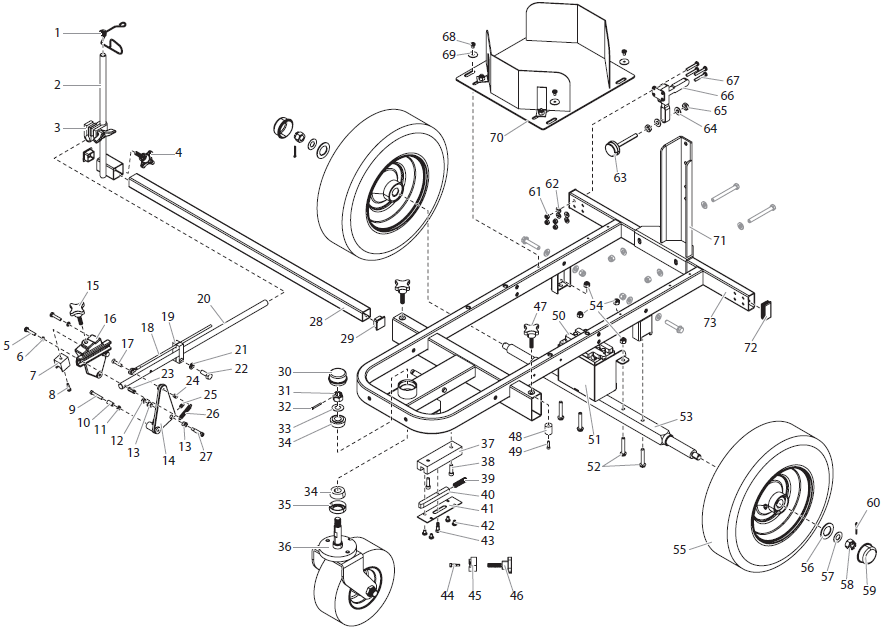

PowrLiner 8950 Cart Assembly I

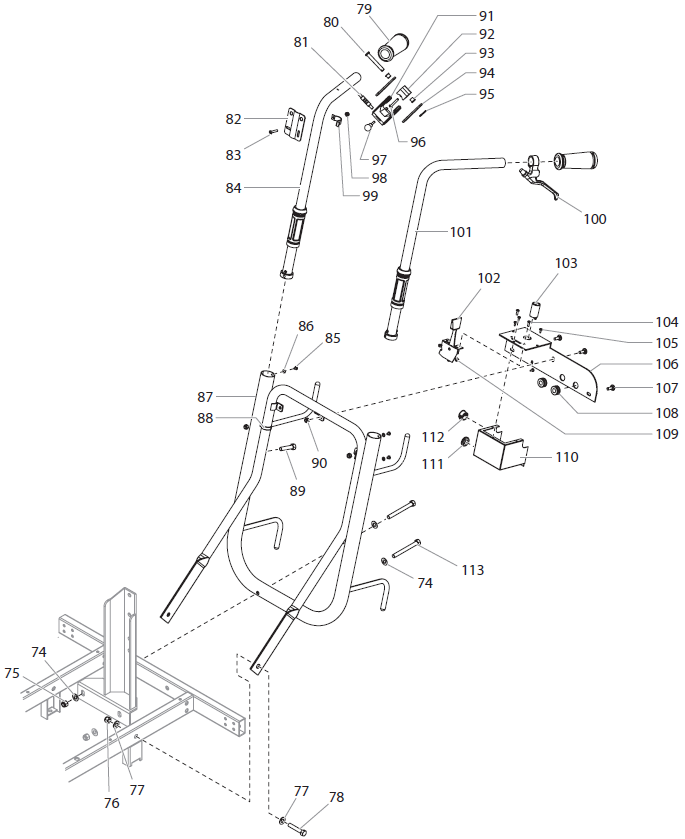

PowrLiner 8950 Cart Assembly II

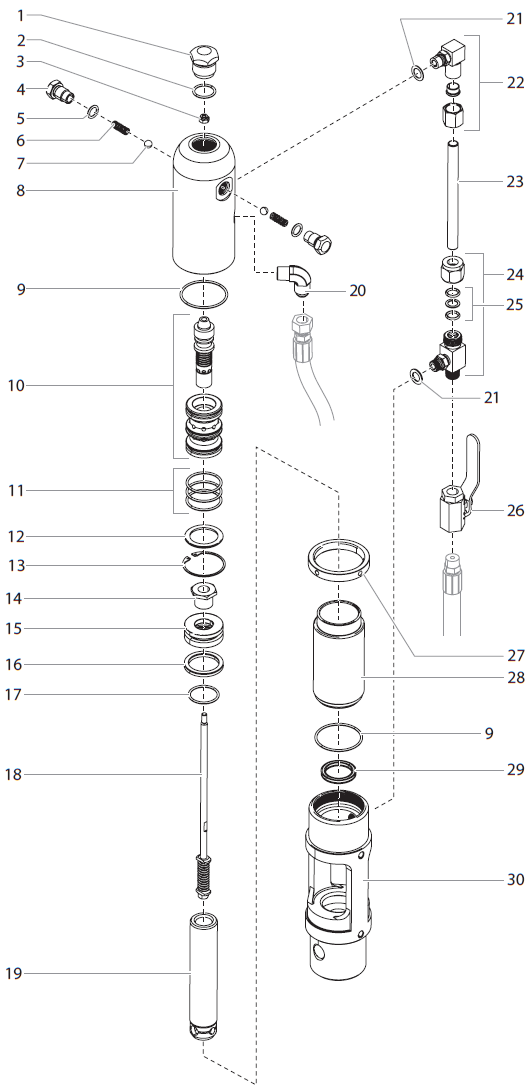

PowrLiner 8950 Hydraulic System

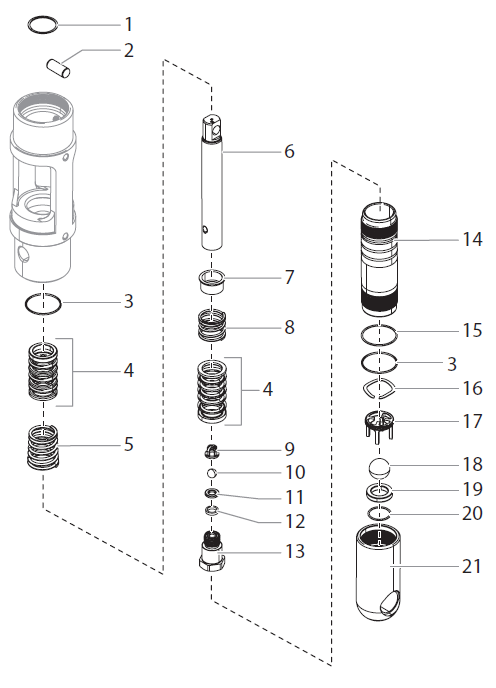

PowrLiner 8950 Hydraulic Motor

PowrLiner 8950 Fluid Section

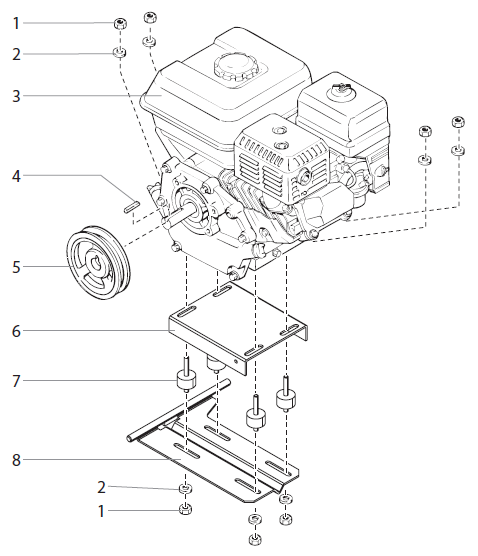

PowrLiner 8950 Gas Convertokit

PowrLiner 8950 Belt Guard Assembly

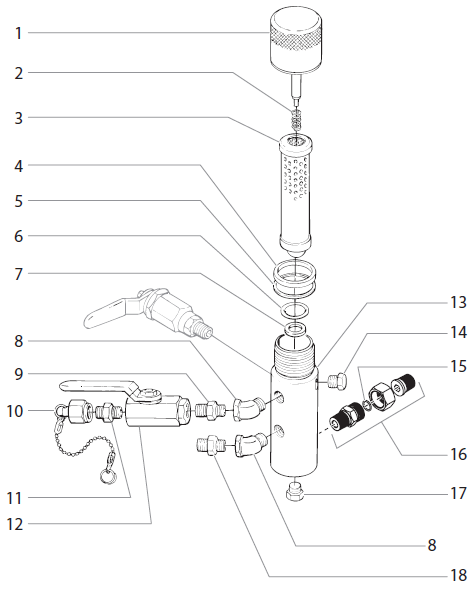

PowrLiner 8950 High Pressure Filter

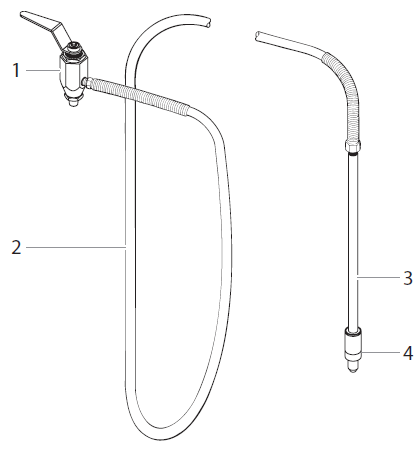

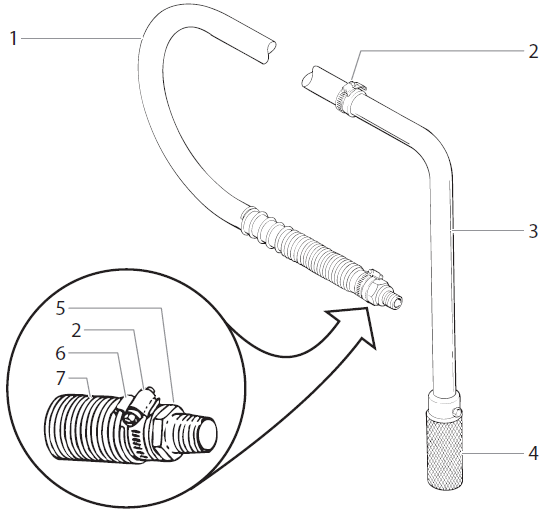

PowrLiner 8950 Bleed Hose Assembly with Valve

PowrLiner 8950 Bleed Valve Assembly

PowrLiner 8950 Siphon Hose Assembly

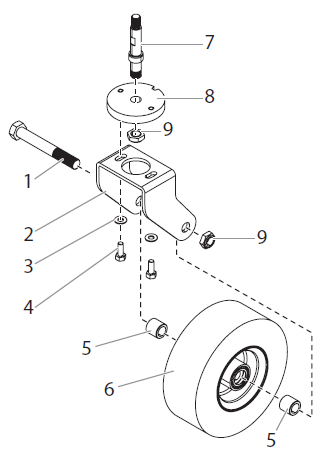

PowrLiner 8950 Caster Assembly

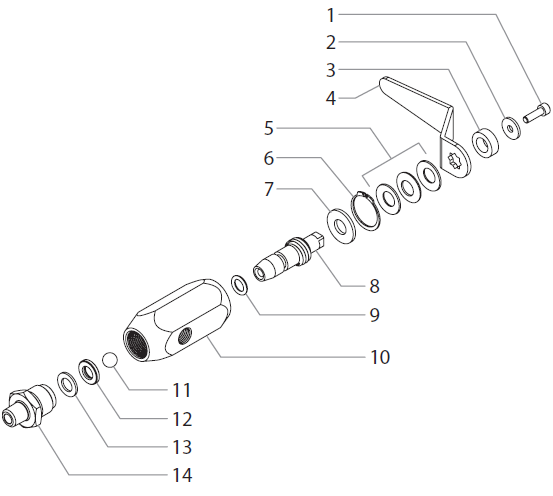

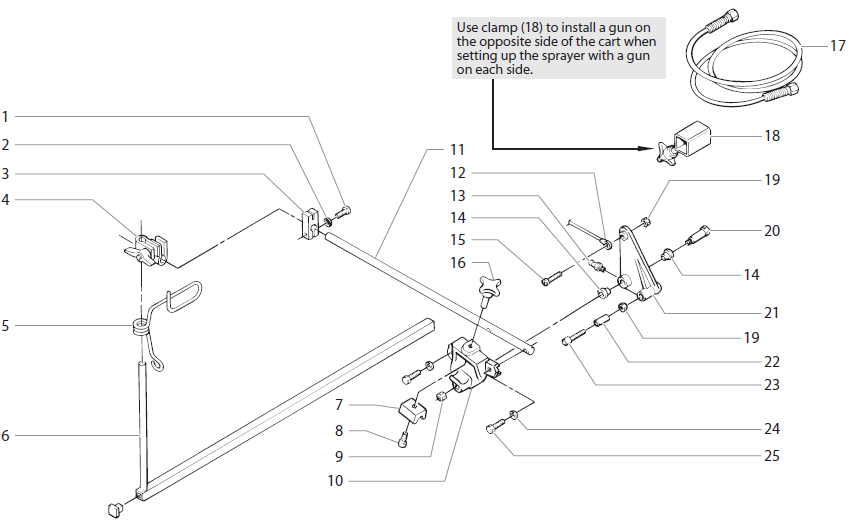

PowrLiner 8950 Second gun assembly

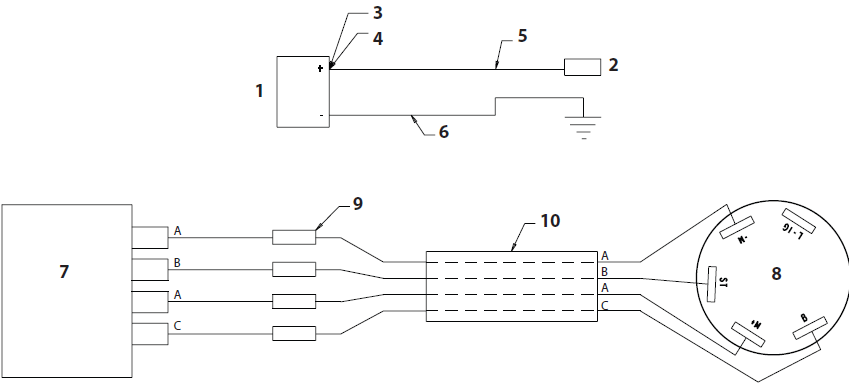

PowrLiner 8950 Connection Diagram

Accessories

NEW PRODUCTS FOR FEBRUARY - POWRLINER 8950

The PowrLiner 8950 is a heavy-duty, high-capacity line striping machine built for contractors who handle large roads, highways, parking lots, and commercial projects. Engineered for continuous, high-pressure performance, it delivers exceptional paint flow, precise control, and long-lasting reliability. With components like the PowrLiner 8950 High Pressure Filter, PowrLiner 8950 Bleed Hose Assembly with Valve, PowrLiner 8950 Bleed Valve Assembly, PowrLiner 8950 Siphon Hose Assembly, and the PowrLiner 8950 Caster Assembly, the system ensures smooth operation and minimized downtime. Its dual-gun capability, supported by the PowrLiner 8950 Second Gun Assembly, makes it ideal for high-volume striping work where speed and accuracy matter.

The filter should be checked and cleaned after each major project. Regular cleaning prevents clogging and helps maintain a consistent spray pattern.

If you notice reduced paint flow, air intake, or hose stiffness, it may be time to replace it to restore proper suction.

It should be inspected for paint buildup, leaks, or sticking. A simple cleaning after each job keeps the priming and pressure release smooth.

Check the PowrLiner 8950 Caster Assembly for wear, debris, or hardened movement. Cleaning or replacing the caster improves overall mobility.

Regularly clean and inspect the PowrLiner 8950 Second Gun Assembly, ensuring both guns are free from clogs and properly aligned for consistent striping quality.