Subcategories

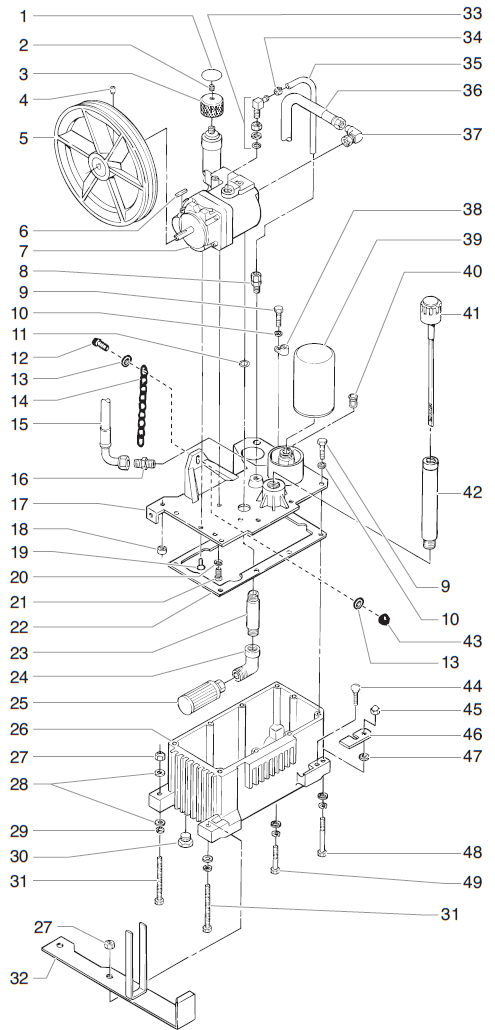

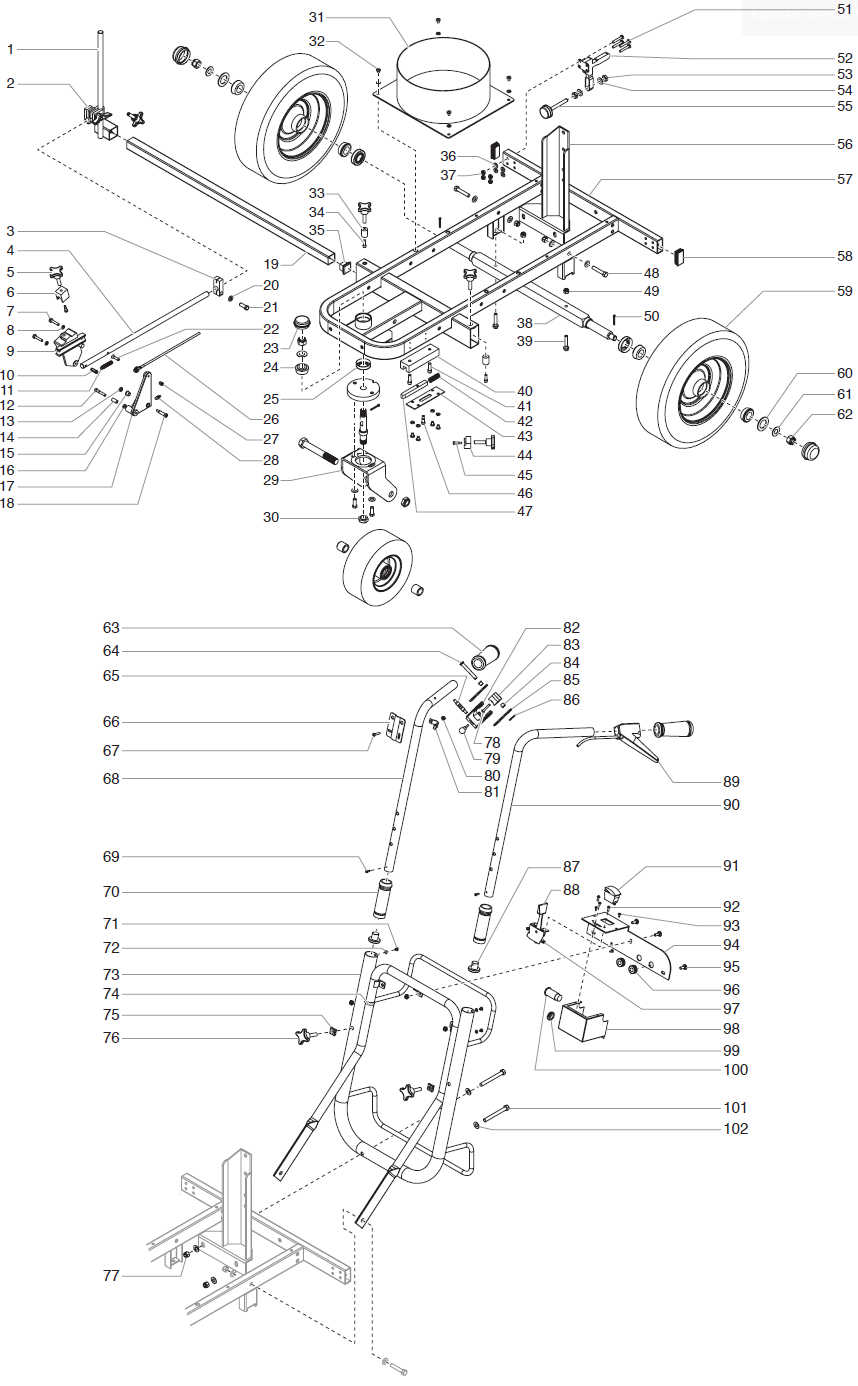

PowrLiner 8900 Main Assembly Parts-Gas Model

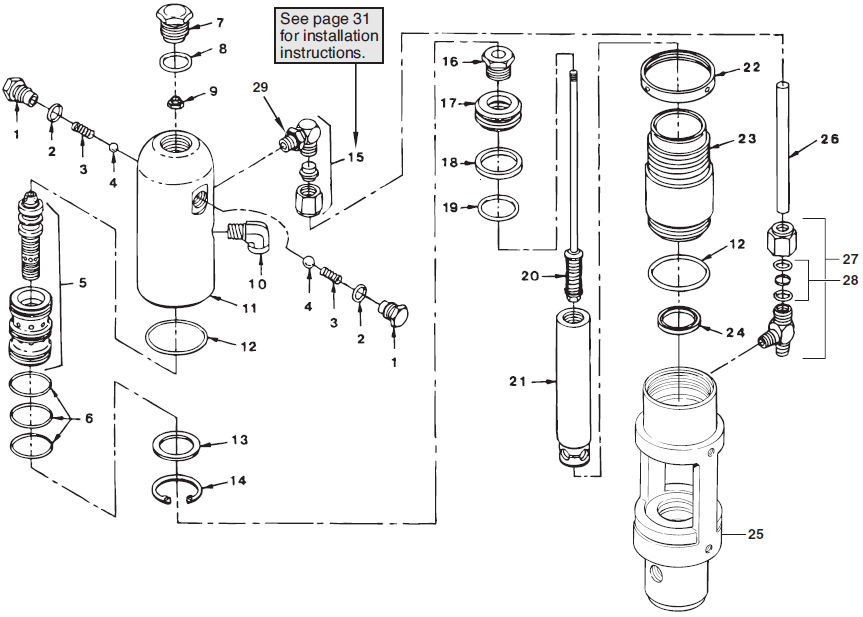

PowrLiner 8900 Hydraulic System Assembly Parts

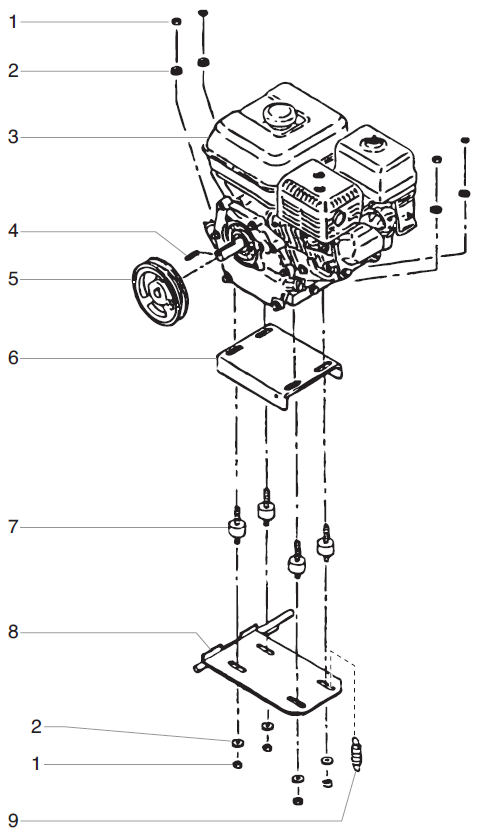

PowrLiner 8900 Gas Convertokit Parts (P/N 506-147)

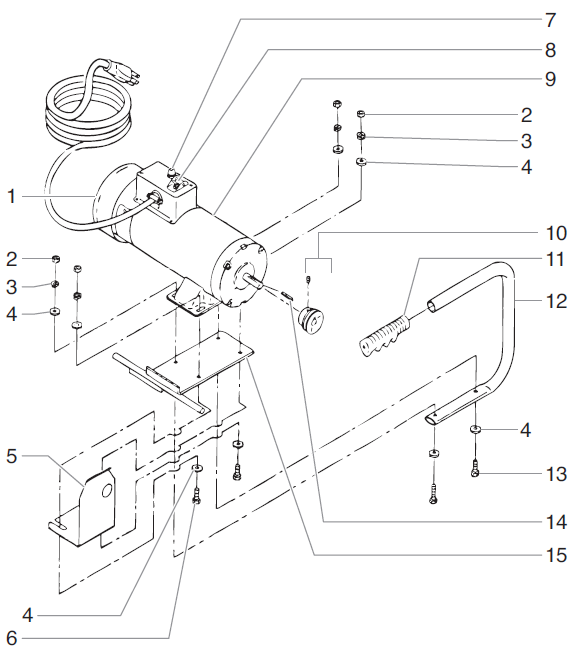

PowrLiner 8900 DC Parts - Electric Convertokits

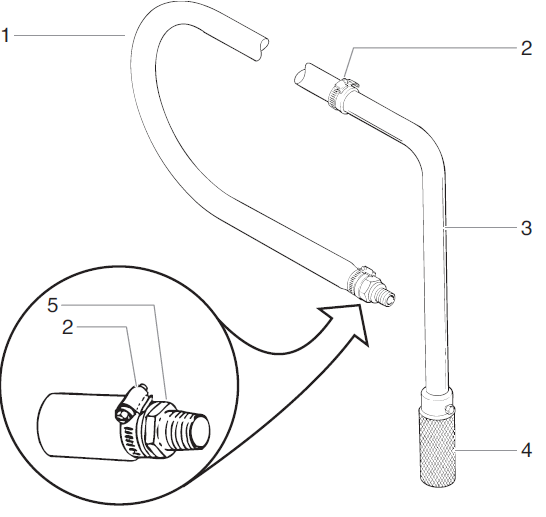

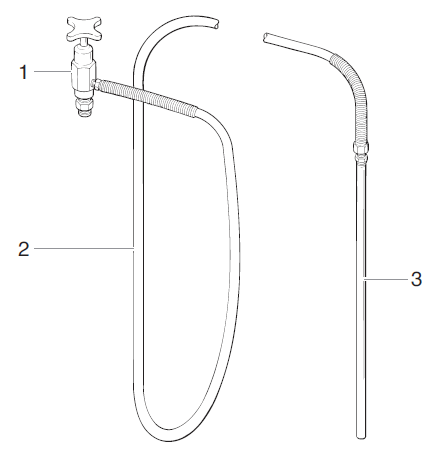

PowrLiner 8900 Siphon Hose Assembly Parts (P/N 103-842)

PowrLiner 8900 Bleed Hose Assembly with Valve Parts (P/N 840-211)

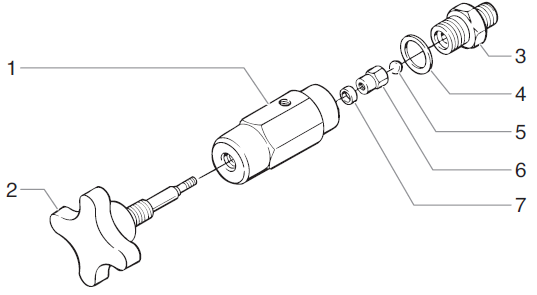

PowrLiner 8900 Bleed Valve Assembly Parts (P/N 944-028)

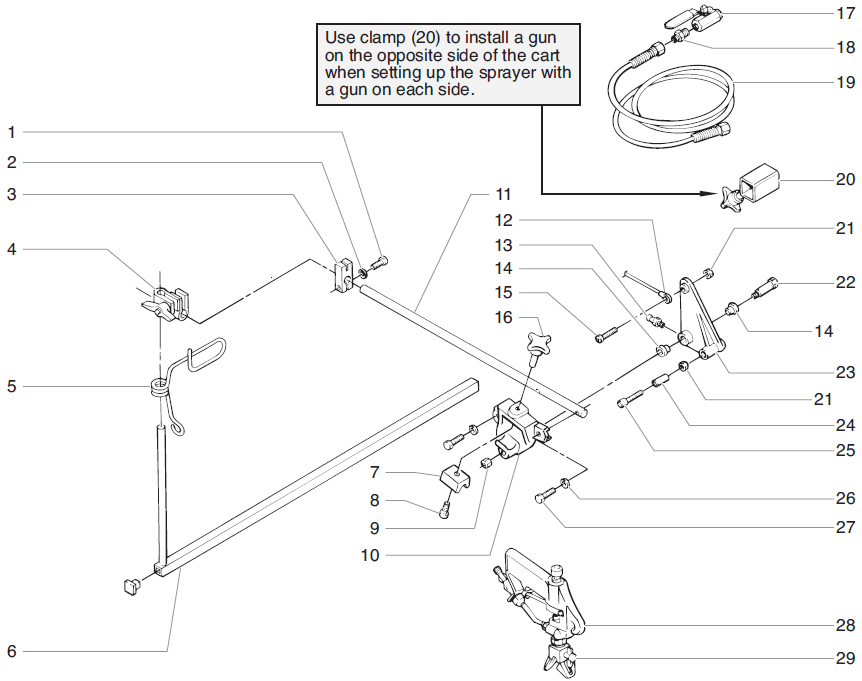

PowrLiner 8900 Cart Assembly Parts (P/N 779-001)

PowrLiner 8900 Hydraulic Motor Parts

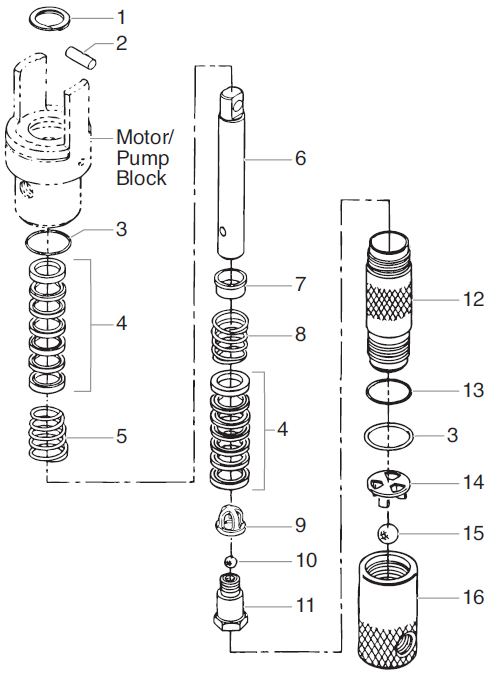

PowrLiner 8900 Fluid Section Parts

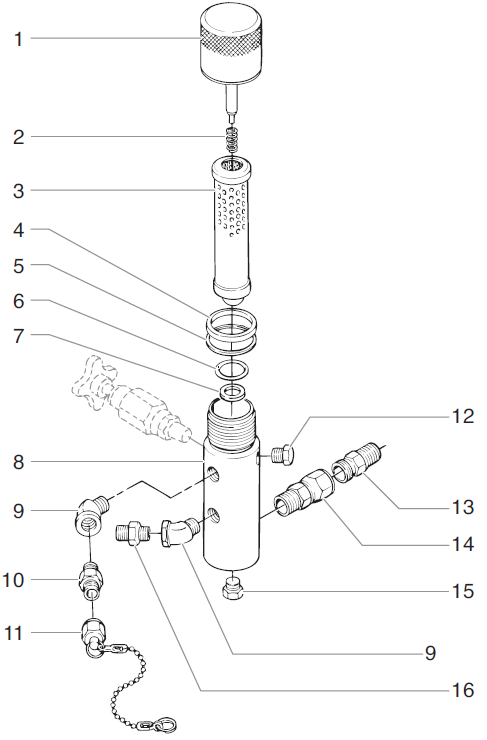

PowrLiner 8900 Filter Assembly Parts

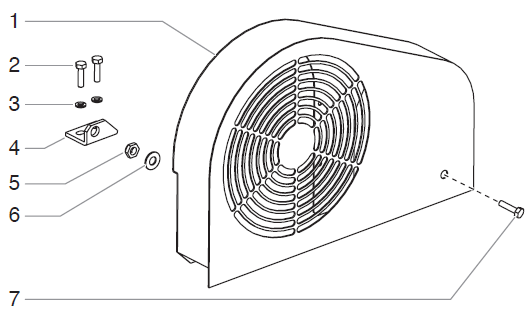

PowrLiner 8900 Belt Guard Assembly Parts

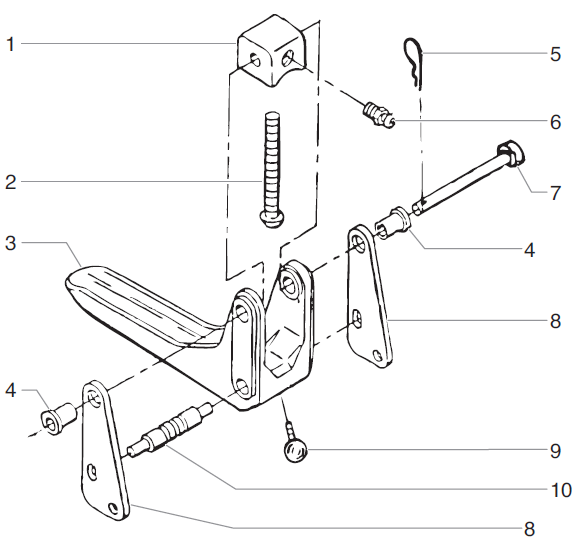

PowrLiner 8900 Trigger Assembly Parts

PowrLiner 8900 Second Gun Assembly Parts

PowrLiner 8900 Accessories Parts

NEW PRODUCTS FOR FEBRUARY - POWRLINER 8900

The PowrLiner 8900 is a powerhouse line striping machine made for the toughest and biggest projects. Contractors love it for highway markings, airport layouts, and large industrial striping because it delivers reliable high-pressure performance all day long. Designed with superior durability and smart engineering, this model keeps productivity high while maintaining precise and professional-looking lines.

Its reliable PowrLiner 8900 Main Assembly Parts – Gas Model form the foundation of its strength, while the advanced PowrLiner 8900 Hydraulic System Assembly Parts ensure smooth pumping and consistent paint delivery. Switching power sources is easy thanks to PowrLiner 8900 Gas Convertokit Parts (P/N 506-147) and PowrLiner 8900 DC Parts – Electric Convertokits, giving you flexibility based on job-site needs. The PowrLiner 8900 Hydraulic Motor Parts and PowrLiner 8900 Fluid Section Parts keep the unit’s performance stable even under heavy workloads.

A favorite among professionals who refuse to compromise on performance, the PowrLiner 8900 is built to deliver job after job.

The PowrLiner 8900 is ideal for:

Flush and clean after each job, inspect the seals regularly, and lubricate moving components to prevent pressure loss and extend pump life.

Yes, the spray gun supports different tip sizes, allowing you to produce various line widths based on project standards.

It is designed with durability and traction in mind, keeping the machine stable on uneven and high-traffic surfaces.

You can adjust pressure, speed, and engine settings quickly to match striping conditions and maintain consistent results.

5. When should I consider replacing the PowrLiner 8900 Hose Assembly?

If you notice cracks, stiffness, or unstable paint pressure, replacing the hose will restore smooth paint flow and help avoid downtime during a job.