Subcategories

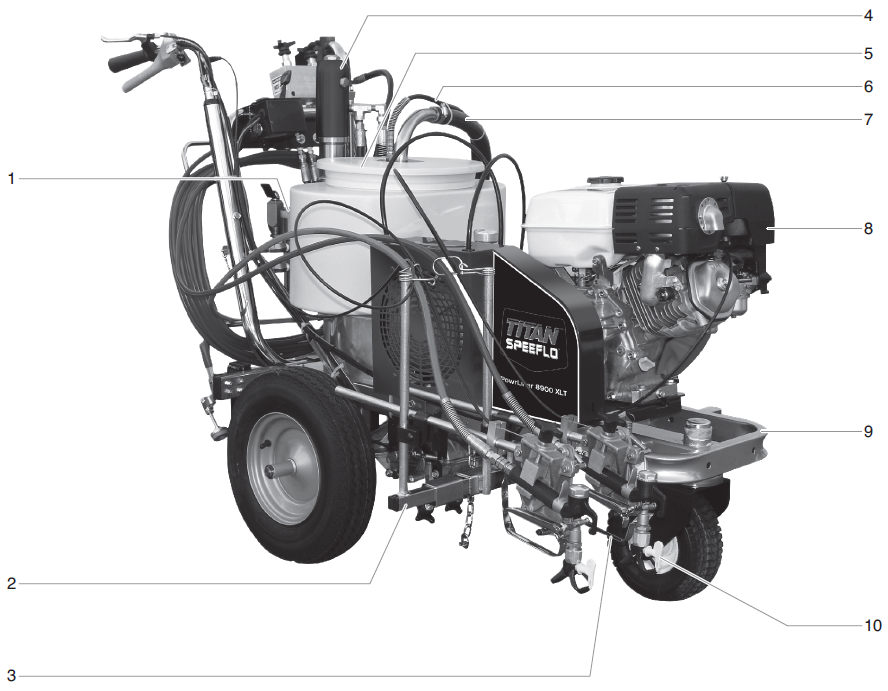

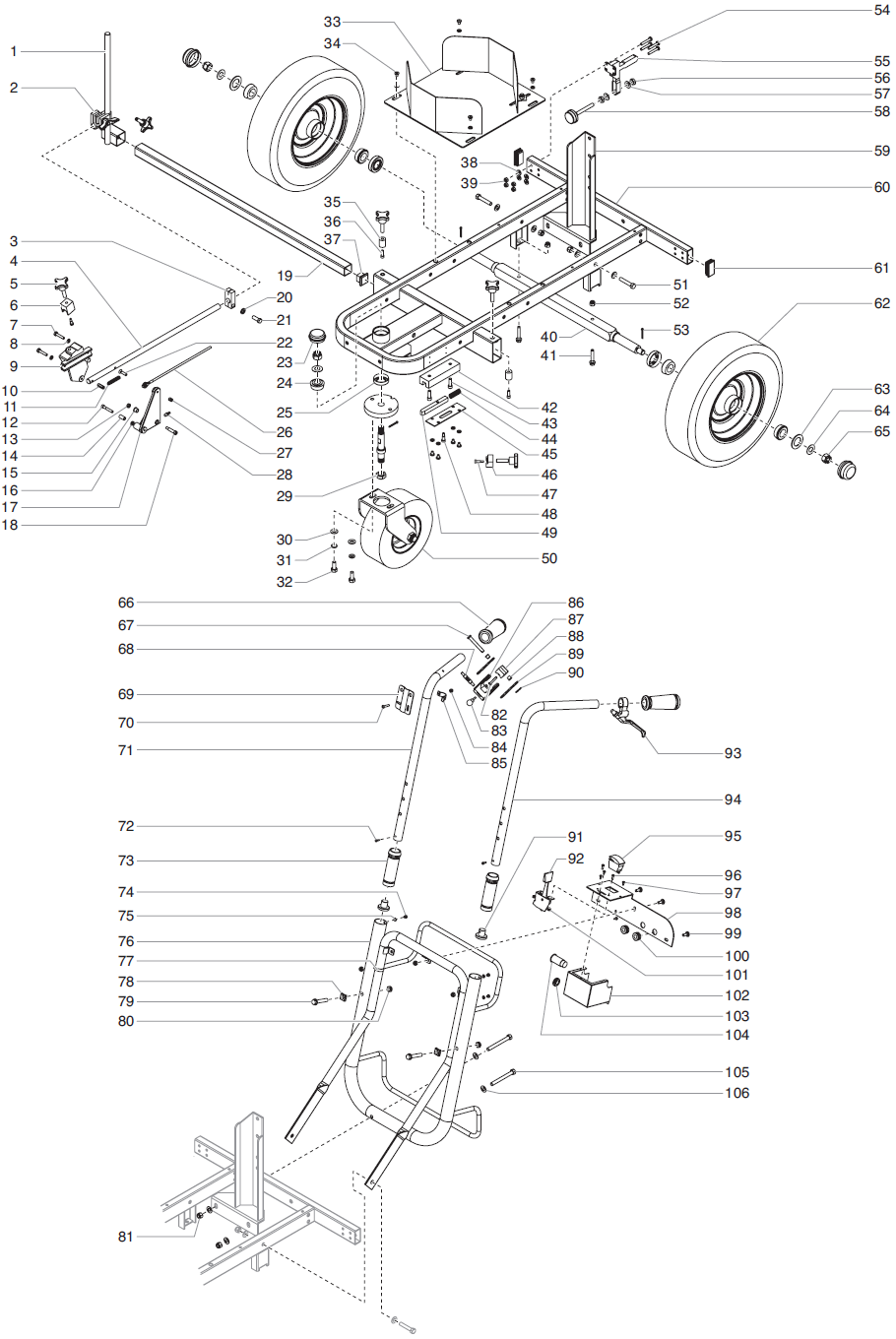

PowrLiner 8900XLT Main Assembly — Gas Model

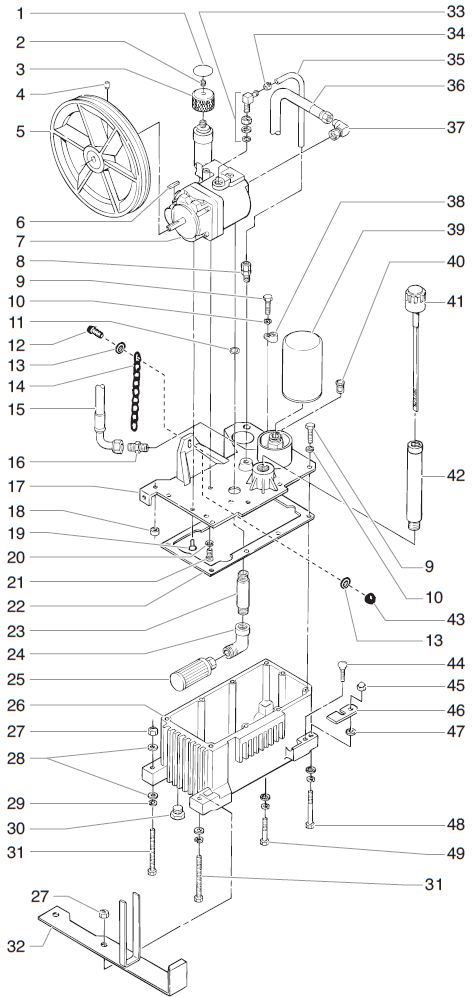

PowrLiner 8900XLT Hydraulic System Assembly (P/N 779-128)

PowrLiner 8900XLT Gas Convertokit (P/N 506-147)

PowrLiner 8900XLT DC — Electric Convertokits

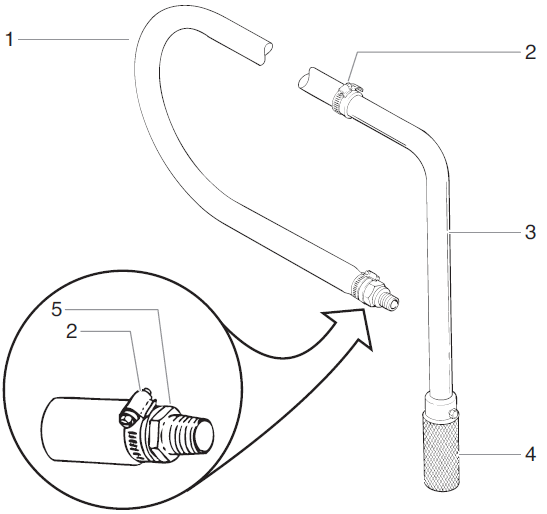

PowrLiner 8900XLT Siphon Hose Assembly (P/N 103-842)

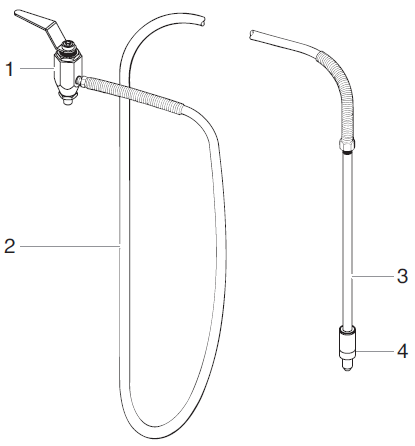

PowrLiner 8900XLT Bleed Hose Assembly with Valve

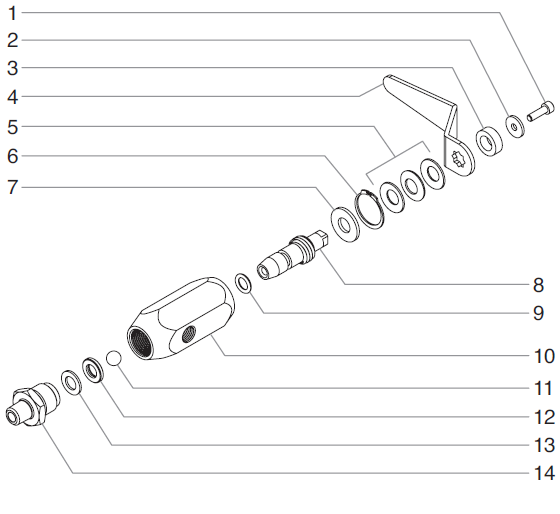

PowrLiner 8900XLT Bleed Valve Assembly (P/N 944-030)

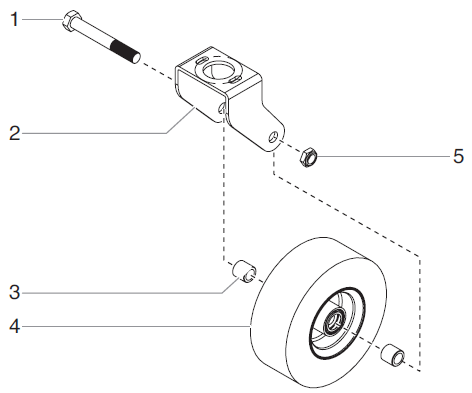

PowrLiner 8900XLT Wheel Assembly

PowrLiner 8900XLT Cart Assembly (P/N 779-564)

PowrLiner 8900XLT Hydraulic Motor

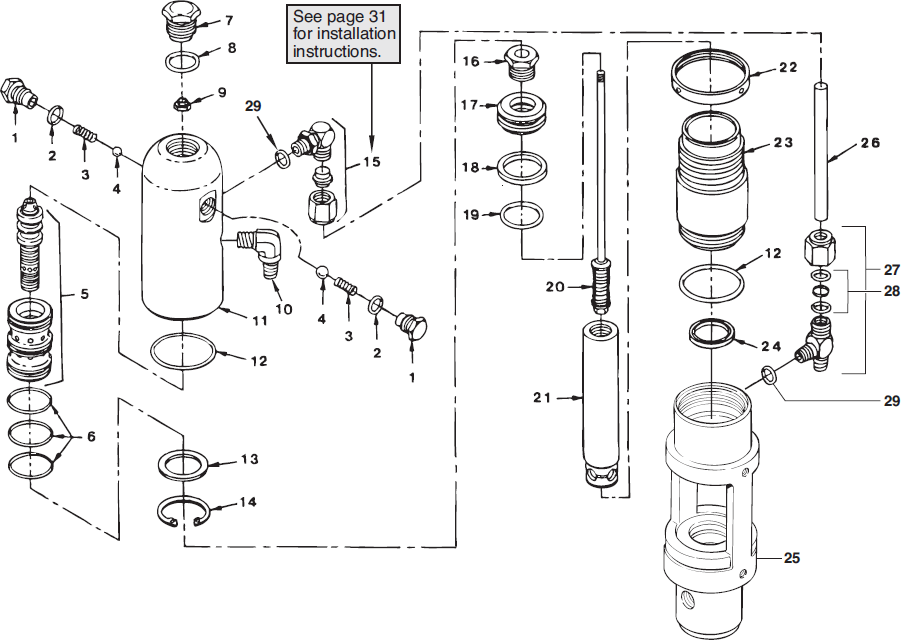

PowrLiner 8900XLT Fluid Section

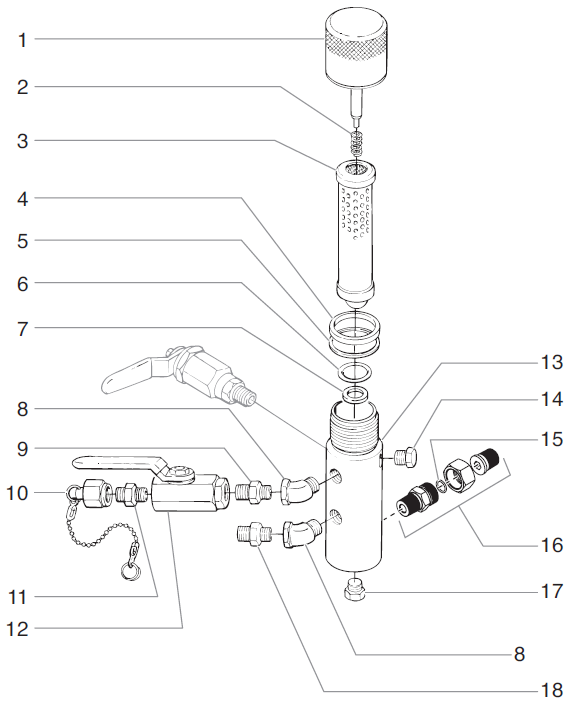

PowrLiner 8900XLT Filter Assembly (P/N 779-098)

PowrLiner 8900XLT Belt Guard Assembly (P/N 449-934)

PowrLiner 8900XLT Trigger Assembly

PowrLiner 8900XLT Second Gun Assembly

Accessories

NEW PRODUCTS FOR FEBRUARY - SPEEFLO POWRLINER 8900XLT

The SPEEFLO PowrLiner 8900XLT is a high-performance line striping machine engineered for contractors who demand speed, precision, and durability on large-scale marking projects. Designed for long workdays and tough job-site conditions, it delivers powerful hydraulic performance and exceptional paint flow control. From parking lots to athletic fields and roadways, the PowrLiner 8900XLT ensures clean, crisp, and consistent lines with every pass. With robust components including the Cart Assembly (P/N 779-564), Hydraulic Motor, PowrLiner 8900XLT Fluid Section, and PowrLiner 8900XLT Wheel Assembly—this system is built to keep you productive with minimal downtime.

FAQs

The hydraulic motor should be inspected regularly and serviced according to usage. Heavy daily use may require more frequent lubrication and cleaning to prevent performance loss.

Irregular spray patterns, pressure drops, or paint pulsing often mean the fluid section components, seals, packings, or valves need cleaning or replacement.

Using clean, filtered paint and routinely checking the PowrLiner 8900XLT Filter Assembly (P/N 779-098) helps reduce blockages and keeps paint flow consistent.

Inspect the Wheel Assembly for damage, wear, or debris buildup. Properly inflated and clean wheels ensure smooth movement across pavement.

If the PowrLiner 8900XLT Trigger Assembly becomes stiff, unresponsive, or causes uneven spraying, it may need cleaning or replacement to restore proper control.