Subcategories

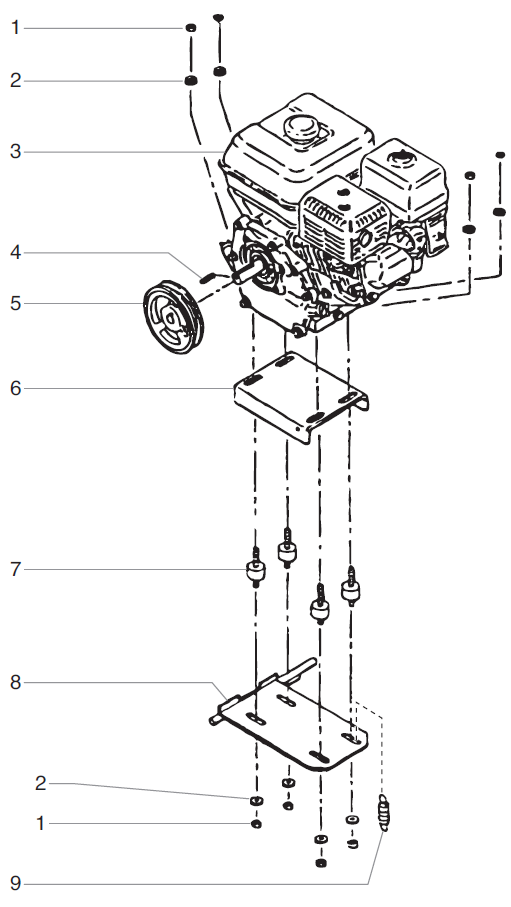

PowrLiner 6900 Main Assembly Parts-Gas Model

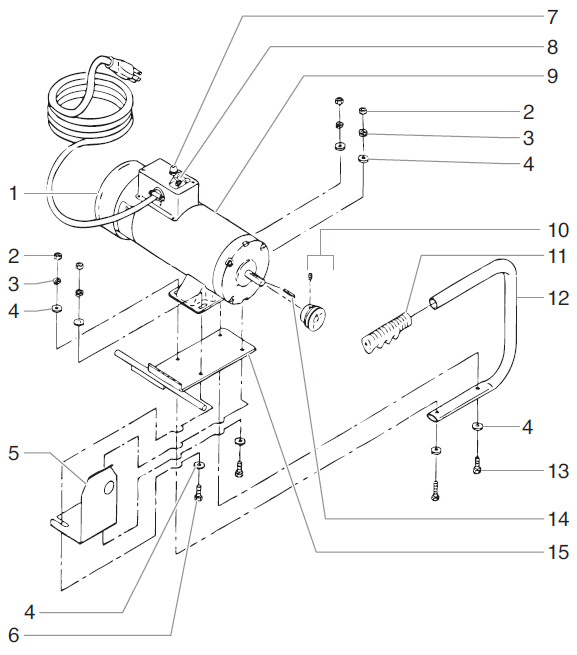

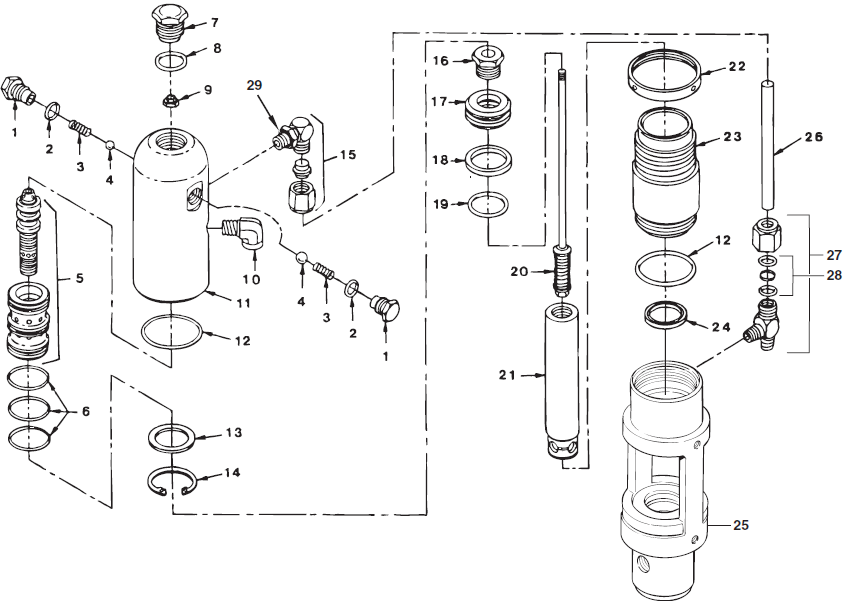

PowrLiner 6900 Hydraulic System Assembly Parts (P/N 779-128)

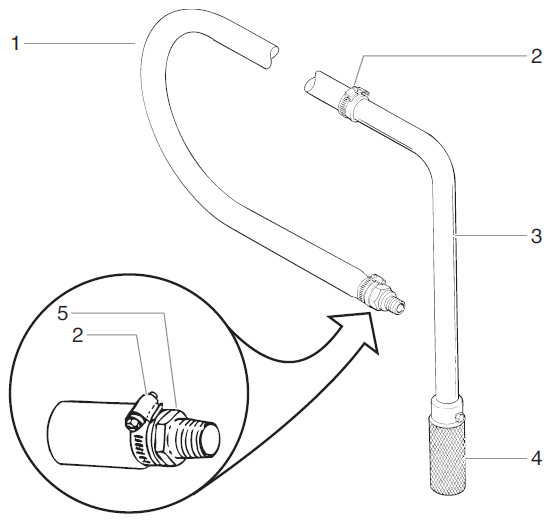

PowrLiner 6900 Gas Convertokit Parts (P/N 506-146)

PowrLiner 6900 DC Electric Convertokits Parts

PowrLiner 6900 Siphon Hose Assembly Parts (P/N 103-841)

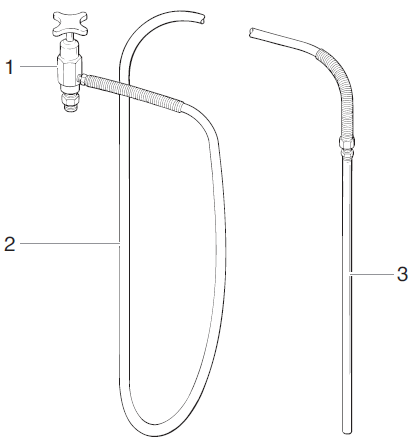

PowrLiner 6900 Bleed Hose Assembly with Valve Parts (P/N 840-211)

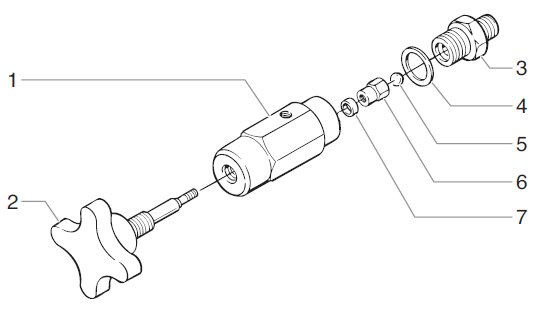

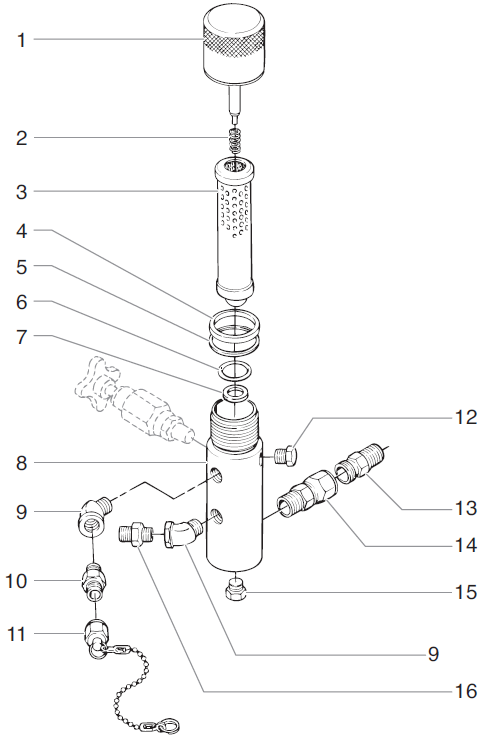

PowrLiner 6900 Bleed Valve Assembly Parts (P/N 944-028)

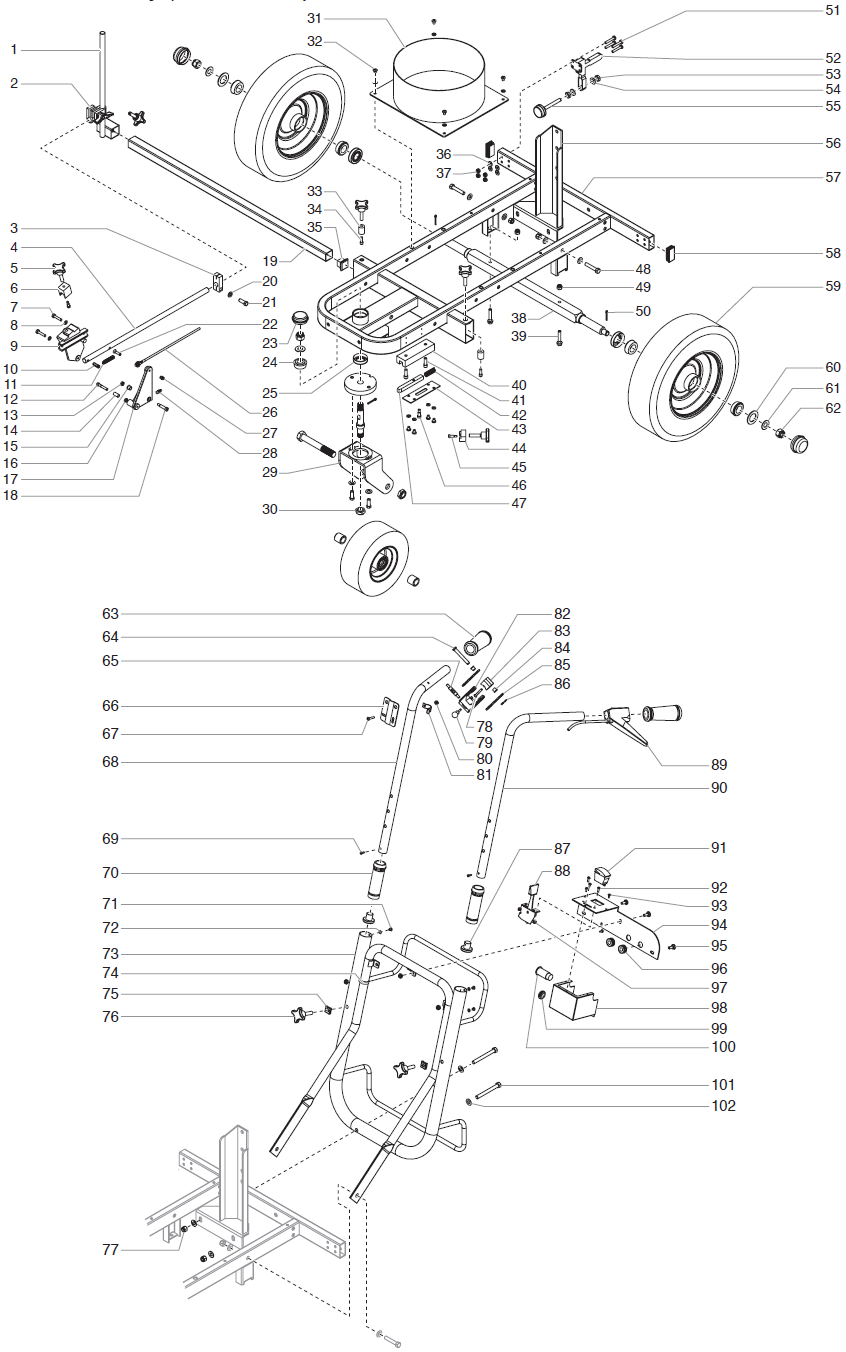

PowrLiner 6900 Cart Assembly Parts (P/N 779-001)

PowrLiner 6900 Hydraulic Motor Parts

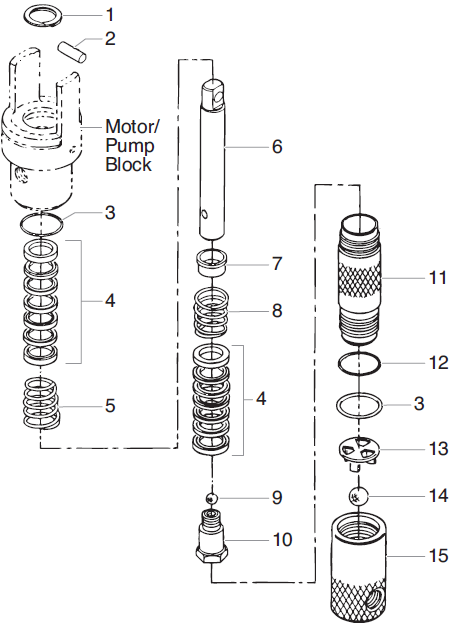

PowrLiner 6900 Fluid Section Parts

PowrLiner 6900 Filter Assembly Parts

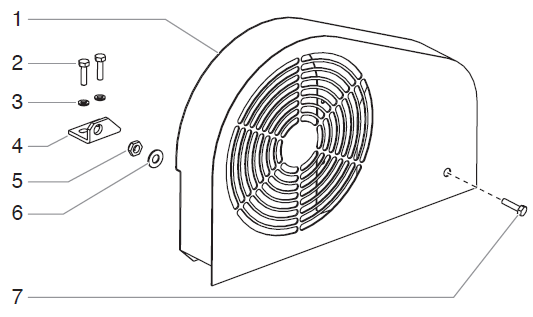

PowrLiner 6900 Belt Guard Assembly Parts

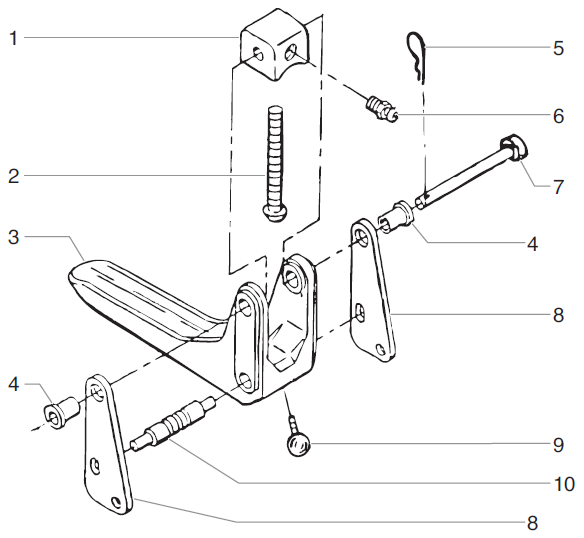

PowrLiner 6900 Trigger Assembly Parts

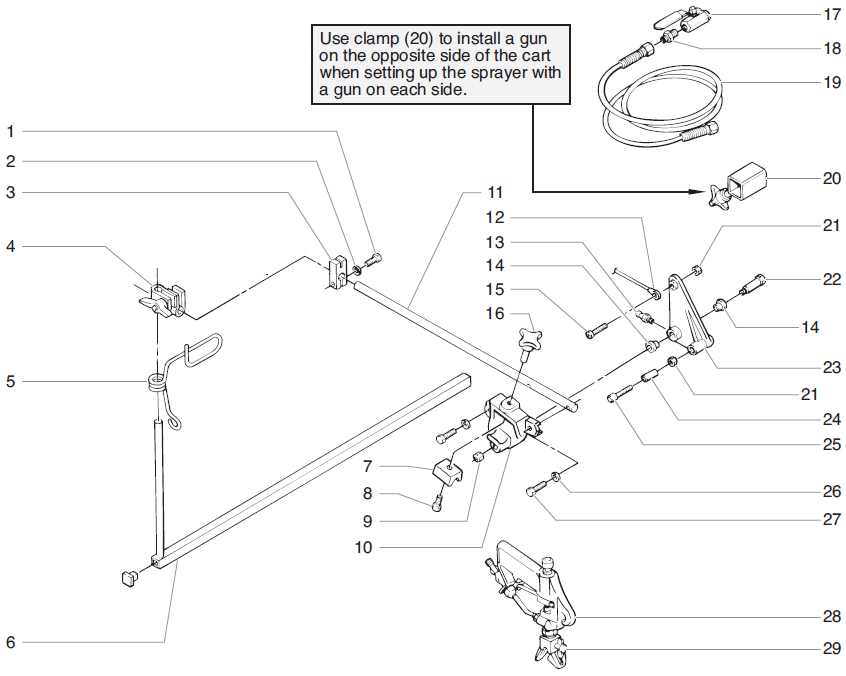

PowrLiner 6900 Second Gun Assembly Parts

PowrLiner 6900 Accessories Parts

NEW PRODUCTS FOR FEBRUARY - POWRLINER 6900

The PowrLiner 6900 is a heavy-duty, contractor-grade line-striping machine built for professionals who tackle large-scale marking jobs from parking lots and roadways to runways, athletic fields, and industrial sites. Designed with rugged reliability and long-term performance in mind, the 6900 combines a powerful engine, a robust hydraulic drive system, and a durable frame to deliver clean, consistent striping even under demanding conditions. Whether you’re doing large parking-area layouts, road markings, or full-scale re-striping, the 6900 offers the strength and efficiency that lets you work hard without worrying about equipment failure.

What makes the 6900 special is not just raw power; it’s its balance of precision, durability, and flexibility. The machine’s hydraulic drive gives smooth, steady pressure and fluid flow, while features like dual-gun capability, high-pressure tolerance, and heavy-duty construction ensure that it can handle everything from standard pavement paints to heavier or solvent-based coatings. For contractors who value reliability, versatility, and long service life, the PowrLiner 6900 is a trusted workhorse.

Heavy-Duty Frame & Construction Built on a robust, epoxy-finished frame designed to resist harsh solvents, corrosion, and rough job-site conditions.

Powerful Hydraulic-Drive System & High-Pressure Output The 6900 is driven by a dependable gasoline engine (with convertibility options) that powers a hydraulic system capable of delivering up to ~3300 PSI (228 bar), allowing it to spray a wide range of coating materials from light-bodied paints to thick traffic paints.

Large On-Board Hopper & Fluid Delivery Capacity With a generous onboard paint hopper (about 45 L / 12 gal), the machine supports large jobs without frequent refills.

Flexible Gun Configuration (1-Gun or 2-Gun Option) The machine supports either single-gun or dual-gun setup, allowing either standard lines or wider/dual lines in a single pass, useful for double-lane parking markings, road lines, or high-output jobs.

Swivel-Caster Front Wheel + Pneumatic Tires for Smooth Operation and Precision Steering. The front caster locks into straight or curved line modes, helping operators maintain clean, accurate lines even on turns or radius layouts; pneumatic tires help absorb shocks on uneven surfaces.

Versatile Power Options (Gas / Convertible Electric) While the standard model uses a Honda 5.5 HP gasoline engine, the design accommodates a conversion kit for electric power, offering flexibility depending on job site restrictions or noise/emissions requirements.

The PowrLiner 6900 is suited for a broad range of professional striping and marking tasks, including:

This sub-category includes components such as the hydraulic motor, drive belts/guard, hydraulic pump, and associated fittings, all essential for powering the fluid pump. The hydraulic system ensures smooth, steady, slow-stroking pump action, which leads to consistent paint flow, longer pump life, and lower maintenance demands.

If you notice poor spray quality, uneven flow, clogs, or difficulty priming, this might indicate worn or clogged filters, or degraded fluid-section components (like valves, seals, or hoses). Routine inspection and timely replacement help maintain consistent line quality and prevent pump damage.

These kits allow you to convert the standard gas converto kits into an electric-powered unit. This is useful when working indoors, in restricted zones, or where noise and emissions must be minimized. It gives you flexibility in different working environments without buying an entirely different machine.

Adding a second gun allows you to spray two parallel lines or wider lines simultaneously, which significantly improves productivity on wide lots or long road jobs (like parking lots or double-lane markings). It helps save time and ensures uniform line application