Subcategories

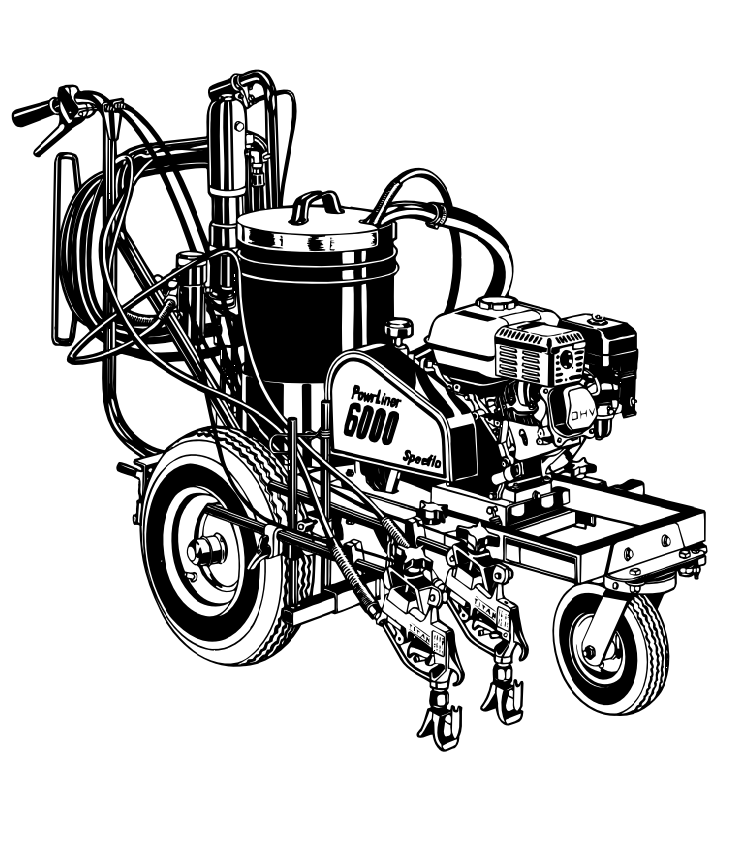

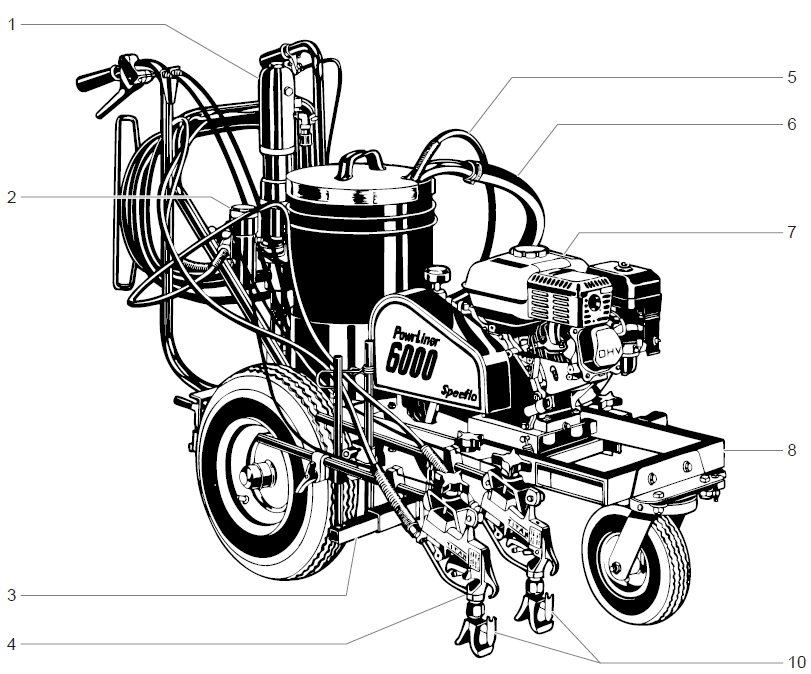

PowrLiner 6000 Main Assembly — Gas Model

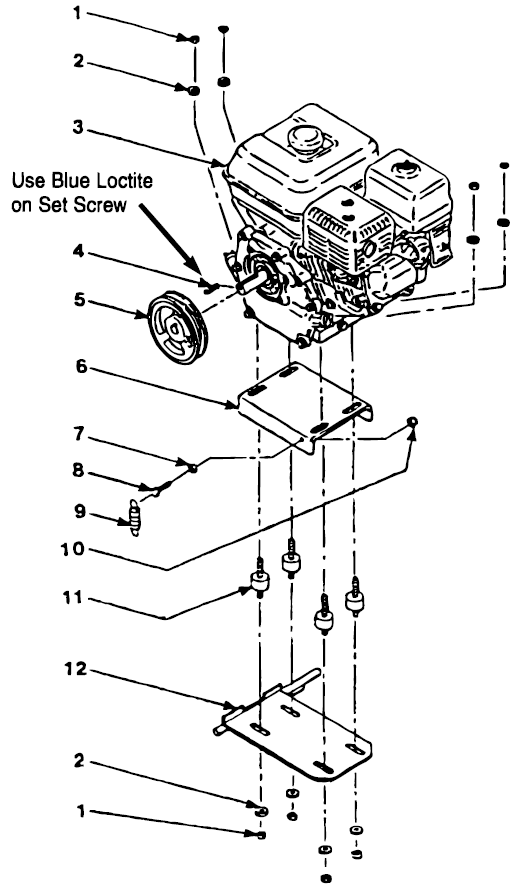

PowrLiner 6000 Gas Convertokits (P/N 506-131)

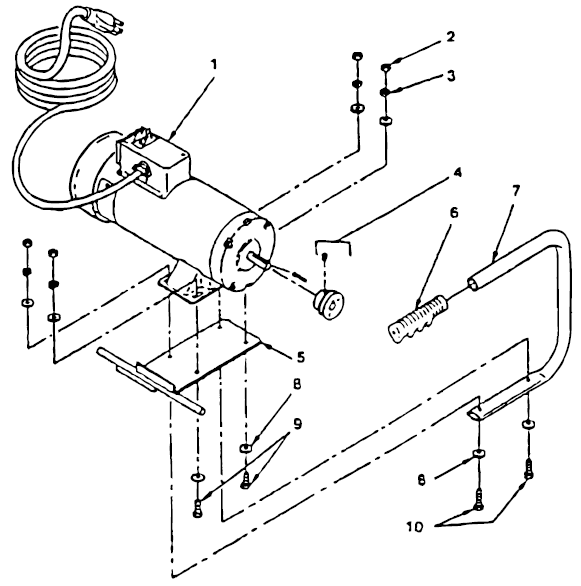

PowrLiner 6000 DC — Electric Convertokit

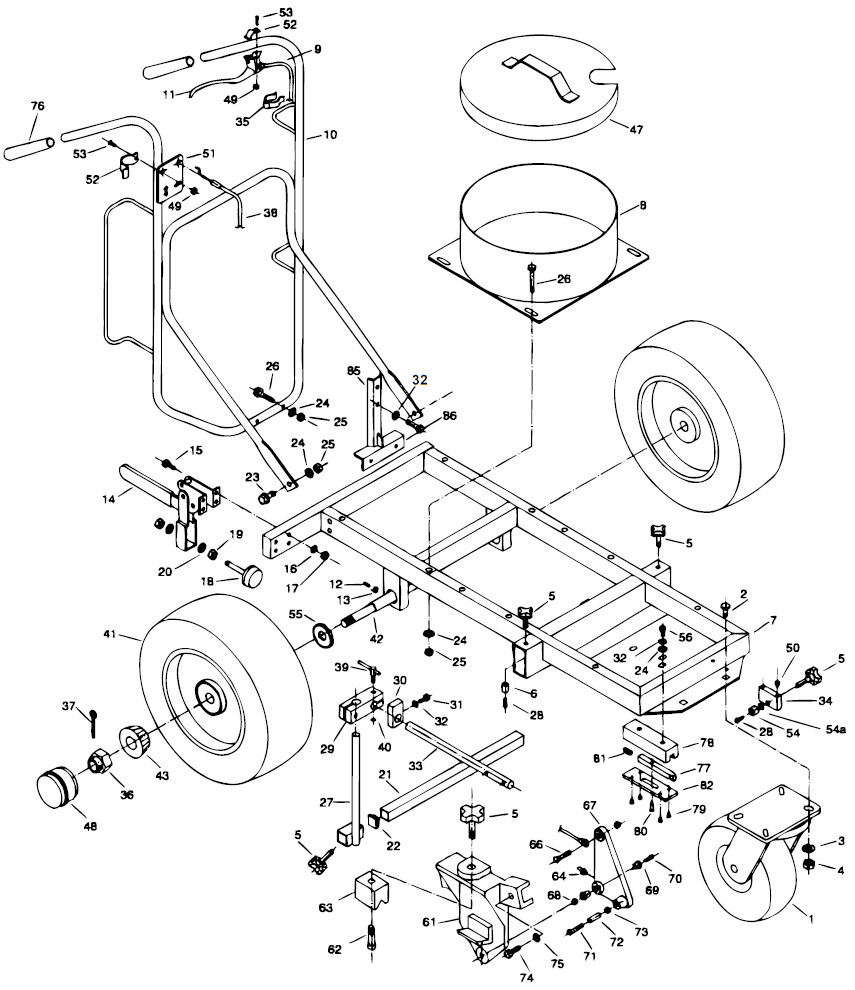

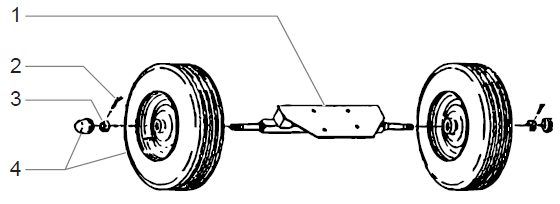

PowrLiner 6000 Cart Assembly (P/N 759-001)

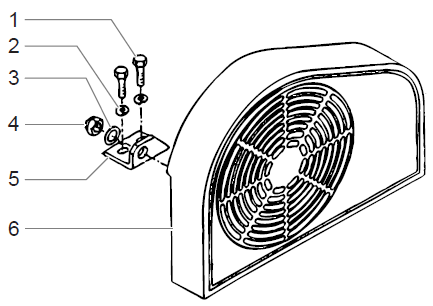

PowrLiner 6000 Belt Guard Assembly (P/N 449-352)

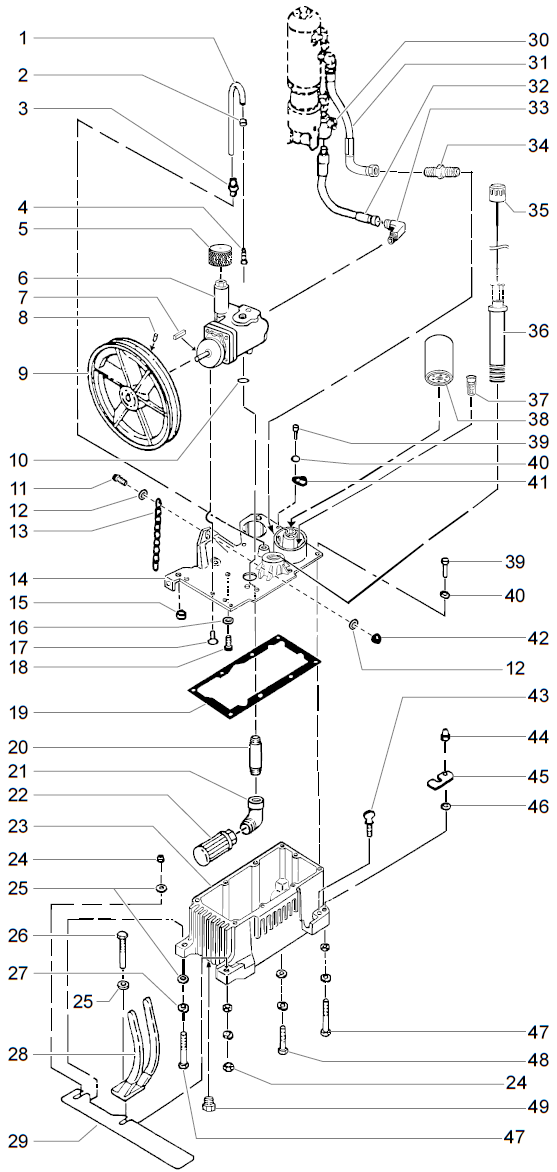

PowrLiner 6000 Hydraulic System

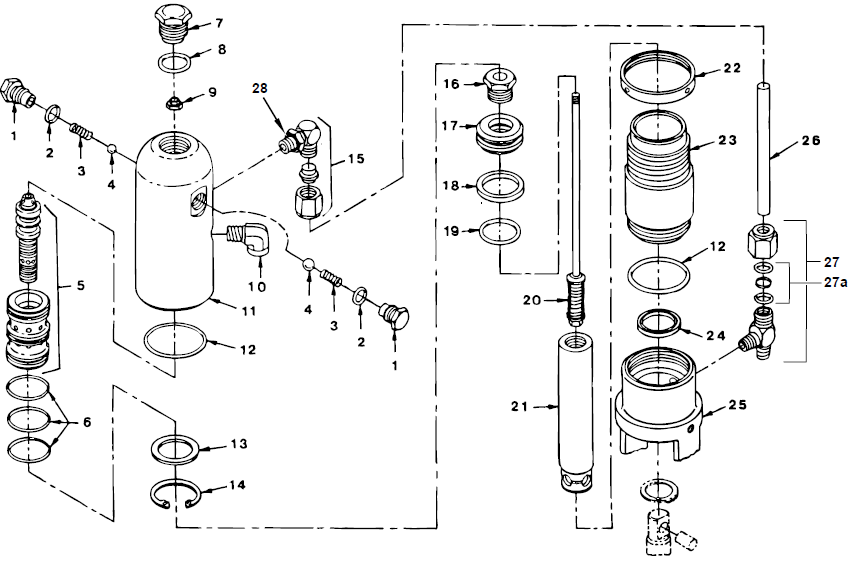

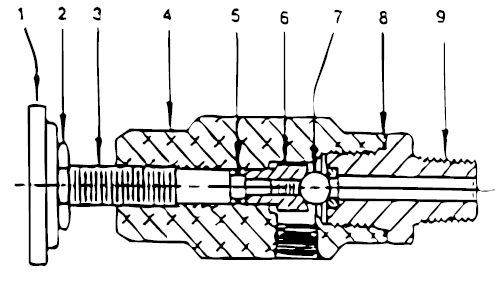

PowrLiner 6000 Hydraulic Motor

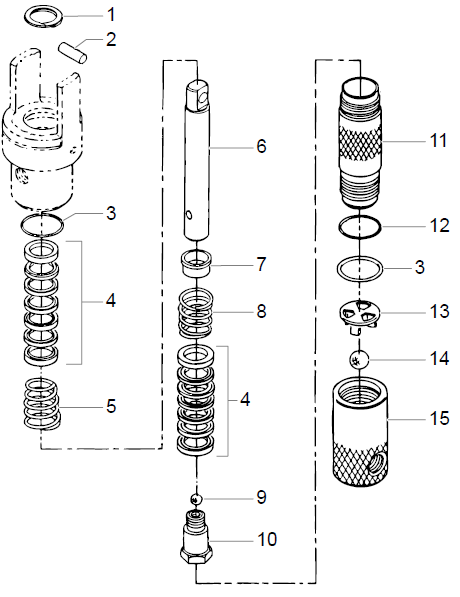

PowrLiner 6000 Fluid Pump

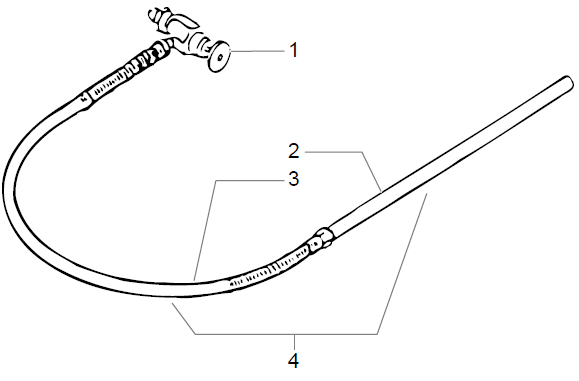

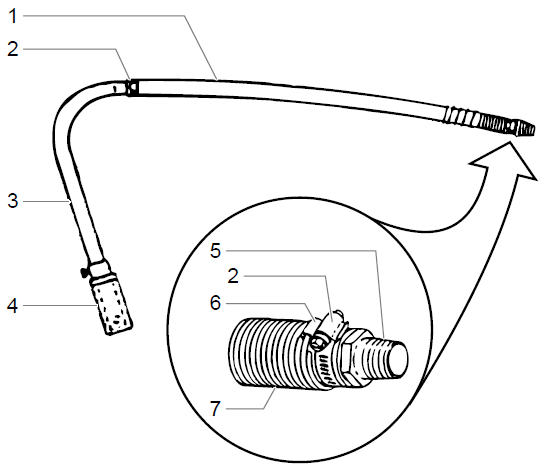

PowrLiner 6000 Bleed Line Assembly with Valve (P/N 840-212)

PowrLiner 6000 Bleed Valve Assembly (P/N 944-620)

PowrLiner 6000 Siphon Hose Assembly (P/N 103-828)

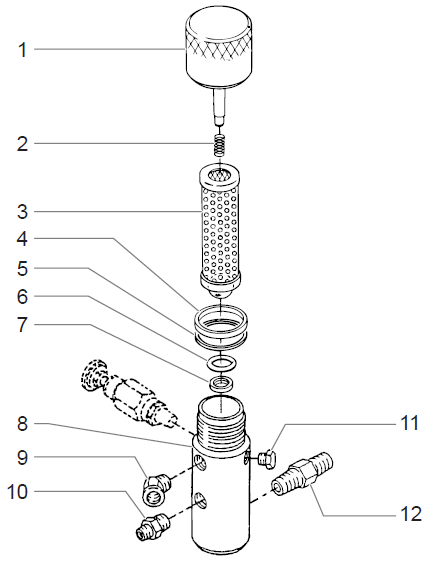

PowrLiner 6000 930 Outlet Manifold Filter Assembly with Check Valve

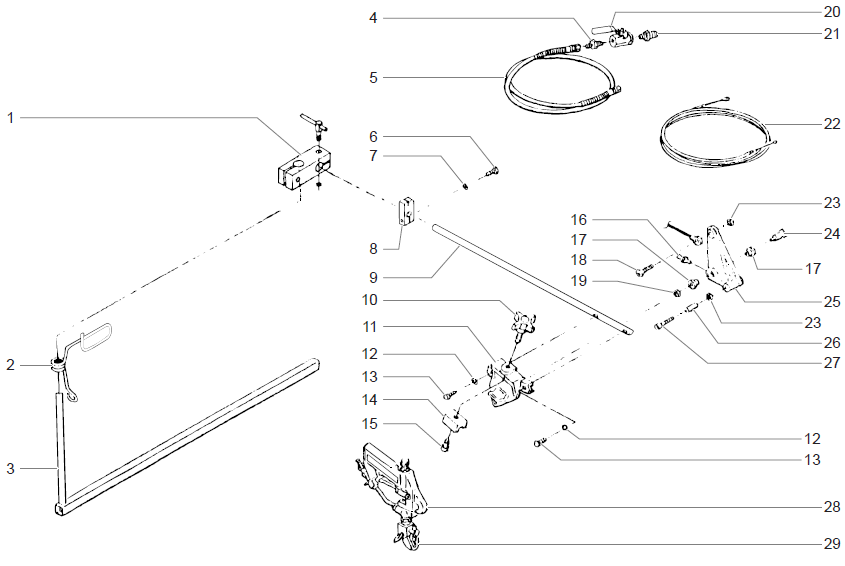

PowrLiner 6000 Second Gun Assembly Complete (P/N 759-038)

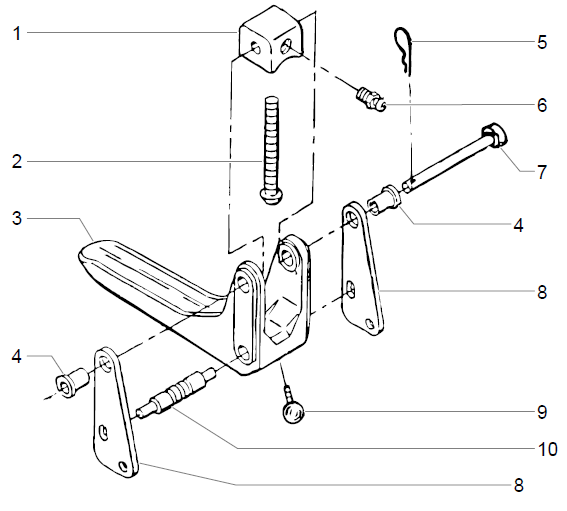

PowrLiner 6000 Trigger Assembly

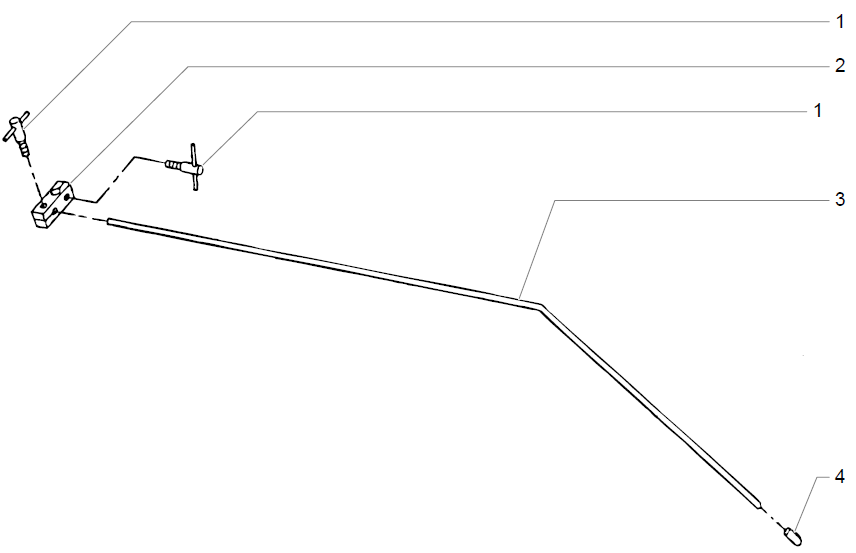

PowrLiner 6000 Line Pointer (P/N 424-620)

PowrLiner 6000 Athletic Field Marking Kit/Turf Kit

Accessories

NEW PRODUCTS FOR FEBRUARY - POWRLINER 6000

The PowrLiner 6000 is a professional-grade airless striping machine designed for demanding, high-volume pavement marking jobs. Built with durability and reliability in mind, the 6000 harnesses a robust hydraulic drive and heavy-duty fluid pump to deliver consistent, clean lines under tough conditions. Its flexible design lets you choose gas or electric power, ideal whether you’re working outdoors on big parking lots, roads, or indoors where low noise and emissions matter. With PowrLiner 6000, professionals get a dependable workhorse that transforms striping tasks from tedious to efficient, letting you focus on quality and speed rather than maintenance.

PowrLiner 6000 is ideal for:

These sub-categories cover the hydraulic drive components that power the pump, including hydraulic motors, drive belts/guards, cart/chassis assemblies, and all associated hardware. They are critical because the hydraulic drive creates the smooth, long-stroke pumping action that gives the 6000 its durability and consistent fluid delivery.

If spray pressure drops, flow becomes uneven, or you notice leaks, it might indicate wear or clogging in the fluid pump, foot valve, siphon hose, or bleed/return line. Regular inspection helps maintain consistent paint delivery and avoids downtime.

Yes. The machine supports a “DC – Electric Convertokit” (or a gas-to-electric conversion kit). This allows converting a gas model into an electric-powered unit, handy for indoor work or environments where emissions or noise are restricted.

This filter assembly ensures that paint or coating material is properly filtered before reaching the spray gun, preventing clogs or uneven spray. The check bleed valve helps maintain correct flow and pressure, assuring consistent, high-quality striping results.

A second gun assembly allows spraying dual lines or wider lines in a single pass, increasing productivity and speed for large jobs like parking lots or long roadway striping. It’s particularly useful where high throughput and efficiency matter.