Subcategories

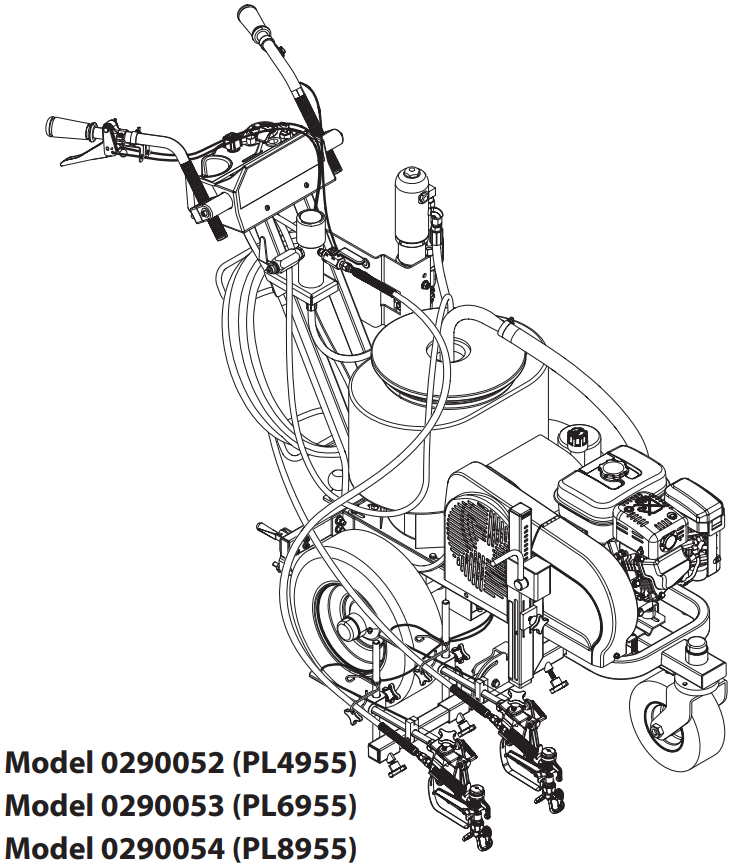

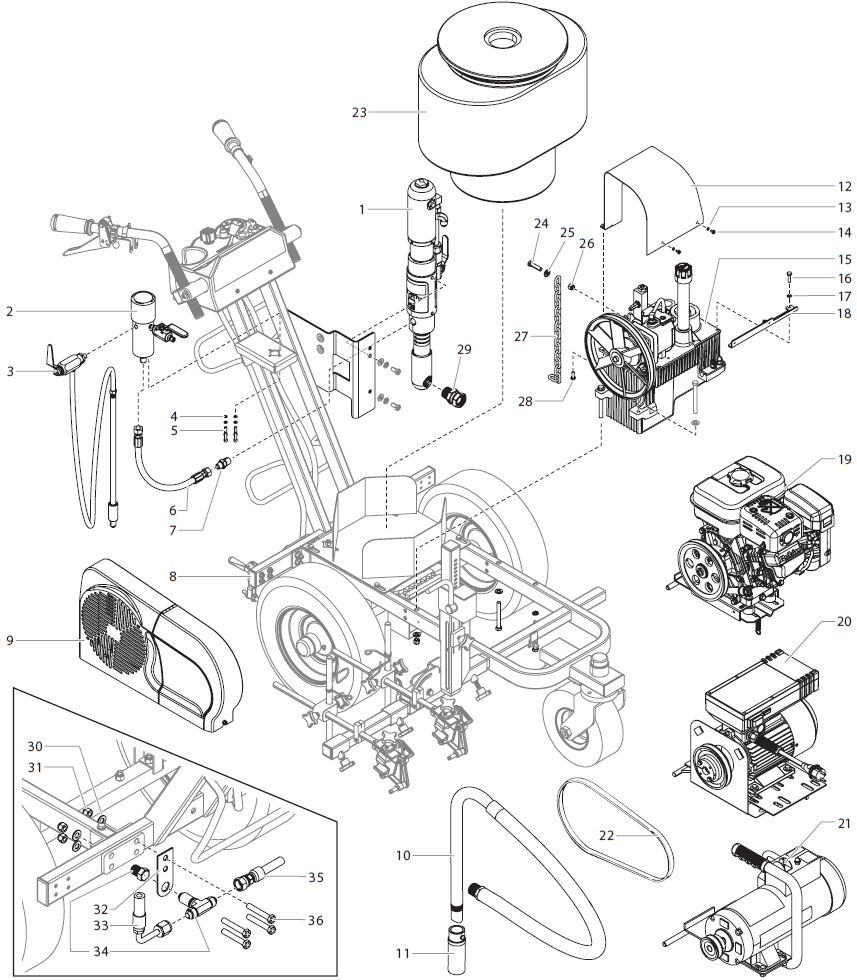

PowrLiner 4955 Main Assembly

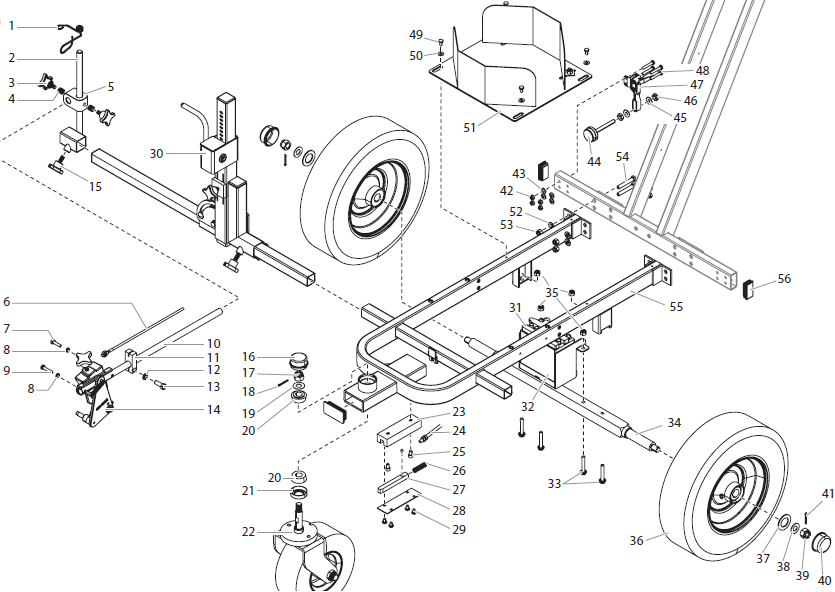

PowrLiner 4955 Cart Assembly I

PowrLiner 4955 Cart Assembly II

PowrLiner 4955 Hydraulic System

PowrLiner 4955 Hydraulic Motor

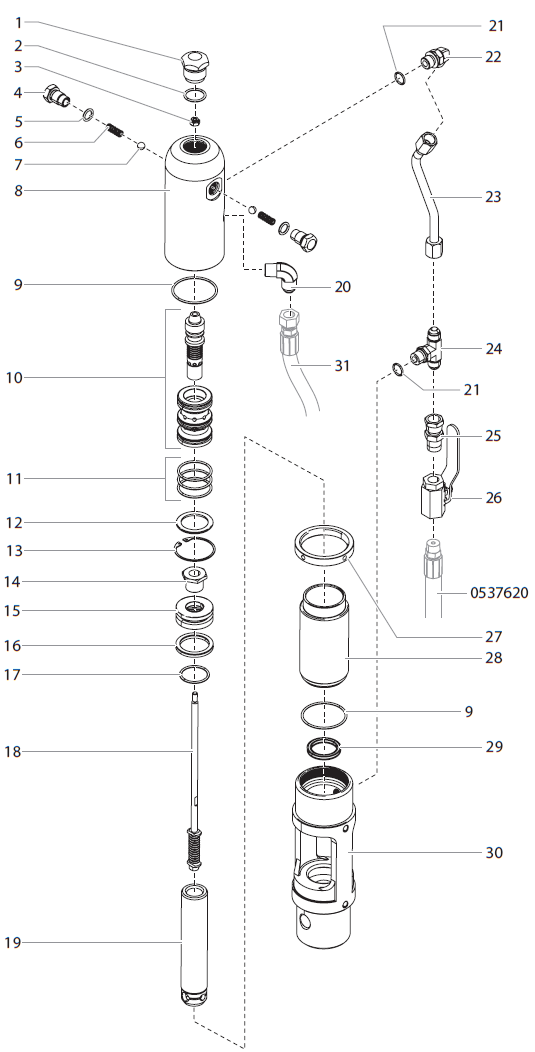

PowrLiner 4955 Fluid Section

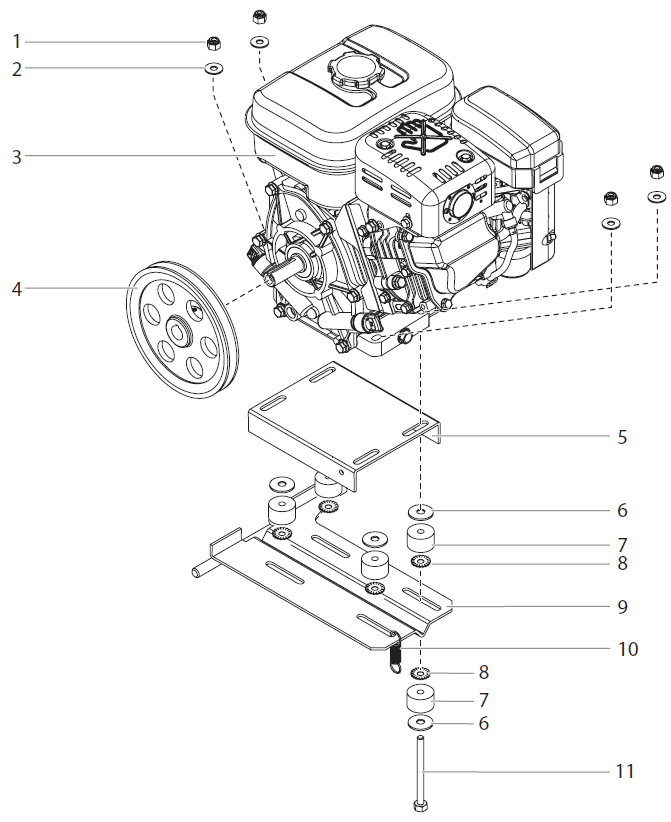

PowrLiner 4955 Gas Convertokit

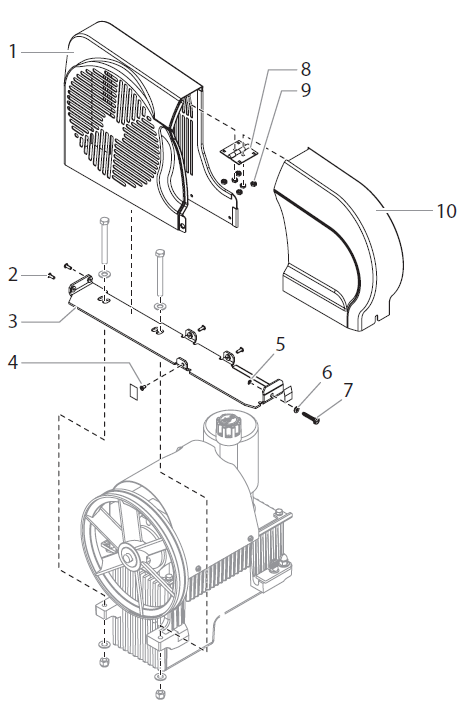

PowrLiner 4955 Belt Guard Assembly

PowrLiner 4955 High Pressure Filter

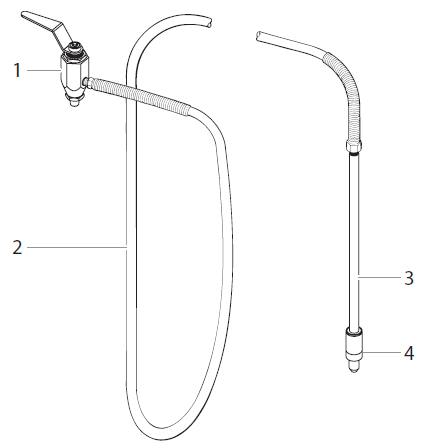

PowrLiner 4955 Bleed Hose Assembly with Valve

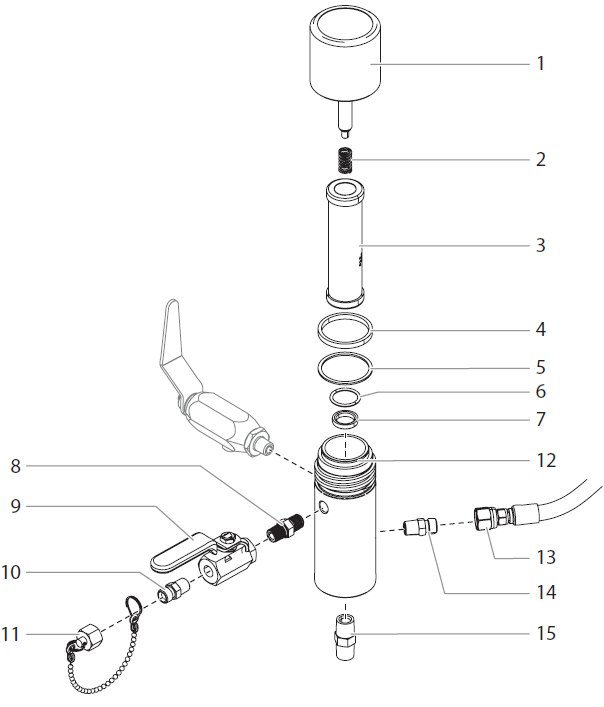

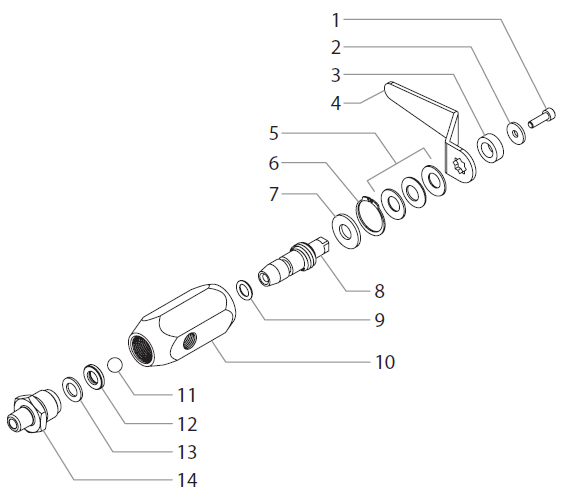

PowrLiner 4955 Bleed Valve Assembly

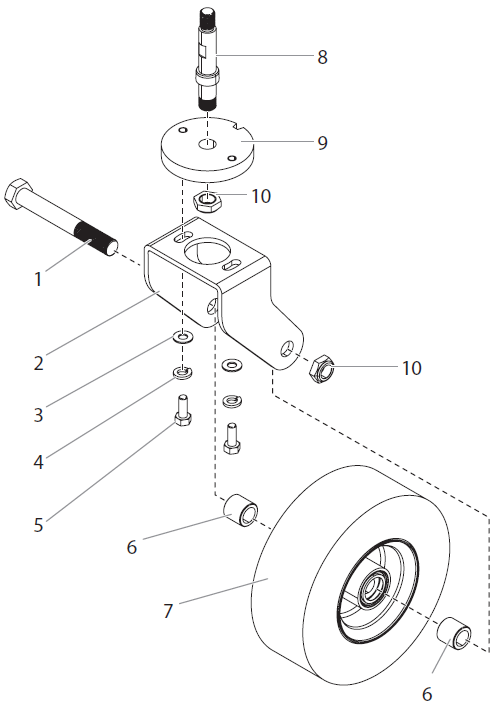

PowrLiner 4955 Caster Assembly

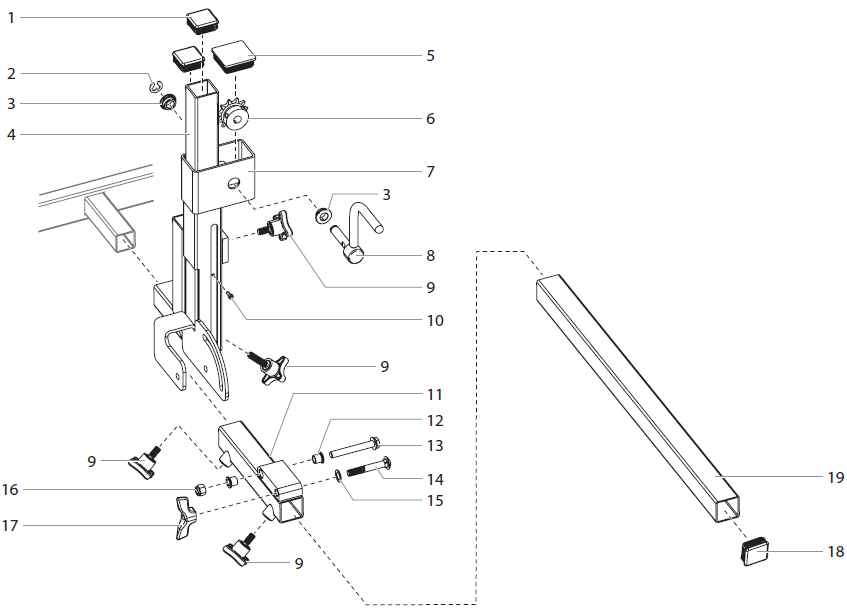

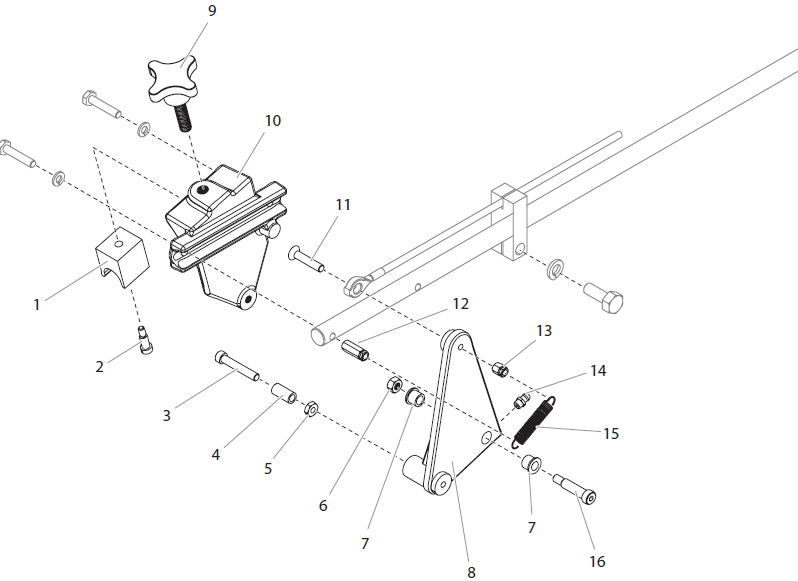

PowrLiner 4955 Lift/Tilt Assembly

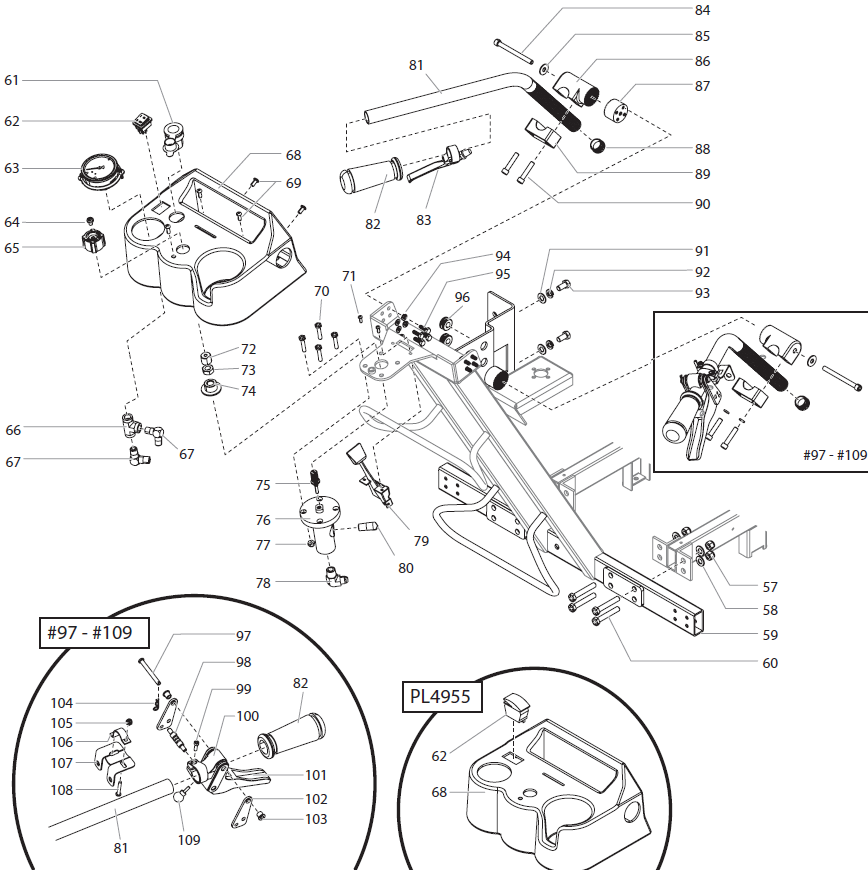

PowrLiner 4955 Gun Holder Assembly

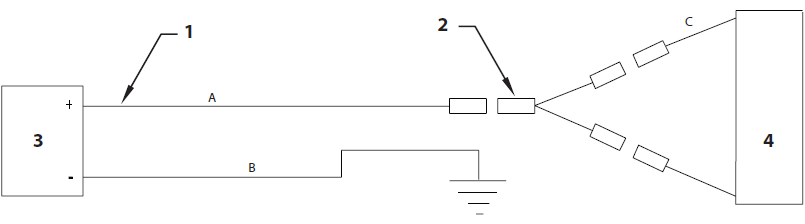

PowrLiner 4955 Connection Diagram

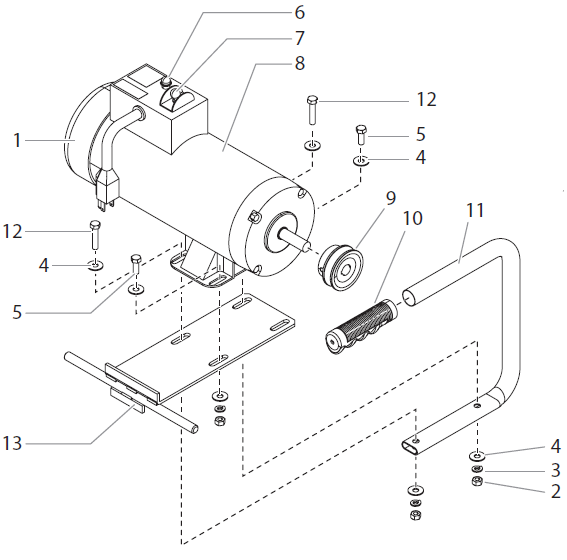

PowrLiner 4955 DC - Electric Convertokit (120V)

Accessories

NEW PRODUCTS FOR FEBRUARY - POWRLINER 4955

The PowrLiner 4955 is a heavy-duty, professional-grade line-striping machine built for contractors who need to complete medium to large-scale striping projects efficiently and profitably. With its powerful hydraulic delivery system, durable construction, and thoughtful ergonomic design, the 4955 is engineered to deliver consistent, high-quality pavement markings on parking lots, athletic fields, roadways, and other large surfaces. It is especially suited for contractors who perform frequent striping jobs and require reliable, long-term performance.

The 4955 model supports one or two-gun configurations, and is compatible with both gas-powered and electric drive (with optional convertor kit), giving you flexibility depending on job-site requirements. It also offers ergonomic handling and easy maneuverability features that improve productivity and reduce operator fatigue.

Whether you’re painting parking-lot lines, lane markings, airport runways, or athletic field boundaries, the PowrLiner 4955 delivers professional striping results with consistency and durability.

The PowrLiner 4955 is ideal for:

These include the main frame, cart/handle assemblies, hydraulic pump and motor, drive belt guard, caster and support assemblies, essentially the core structural and drive components of the machine.

The Fluid Section includes the paint hopper or reservoir, suction and return systems, filters, fluid hoses, high-pressure hoses, valves, and seals, all components involved in storing, transferring, and pressurizing the striping paint or coating.

If spray quality deteriorates, high-pressure filter fluctuates, or the pump seems to strain, it may signal a clogged filter or a worn bleed hose/valve. Replacing these parts helps restore consistent flow and maintain line quality.

Yes, the “DC Electric Convertokit (120V)” provides the parts needed to convert from a gas-powered engine to an electric motor setup, which is convenient for locations where gas engines are restricted or electric power is preferred.

These are structural/safety-related components; replacing them becomes necessary if the belt guard is damaged (exposing moving components) or if the lift/tilt mechanism is no longer holding the spray arm properly, which could compromise operator safety or machine stability.