Subcategories

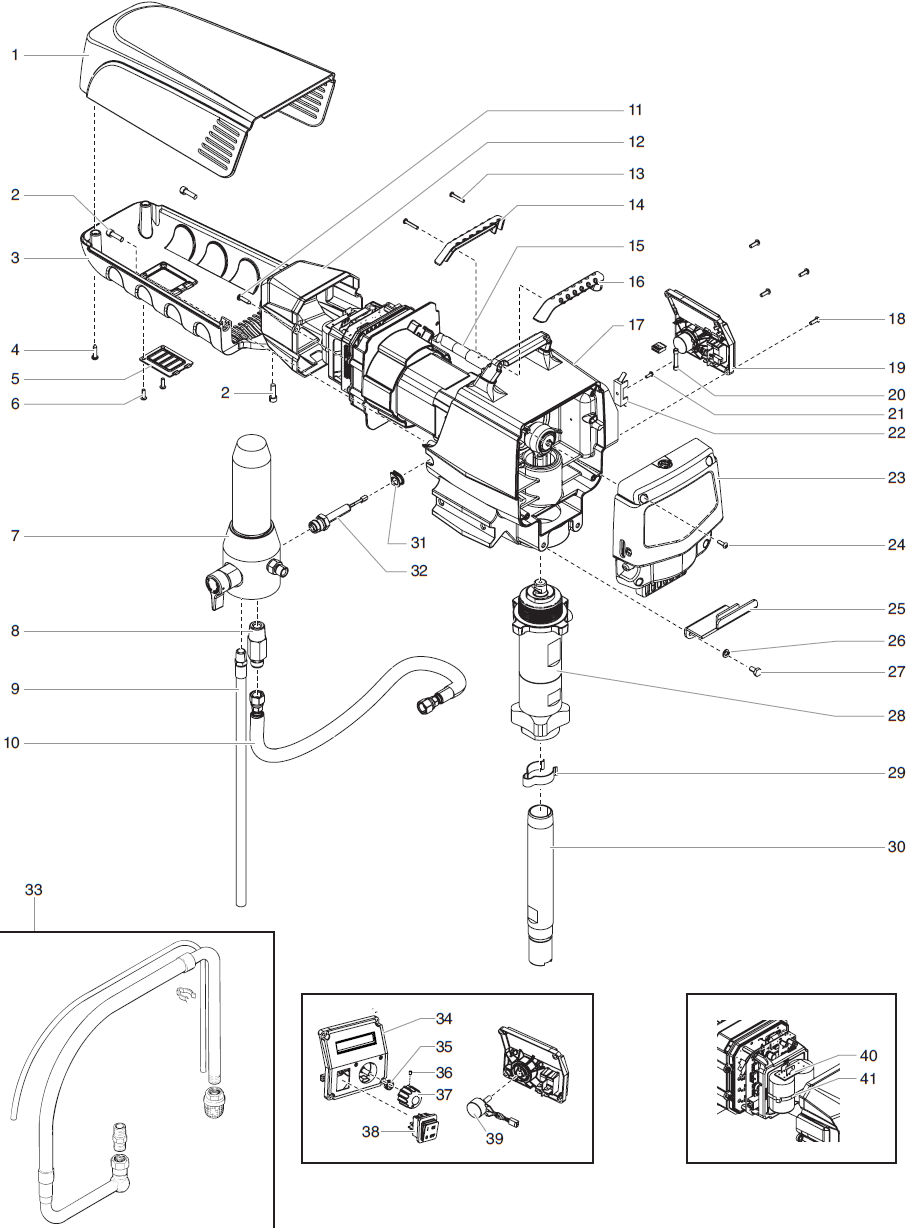

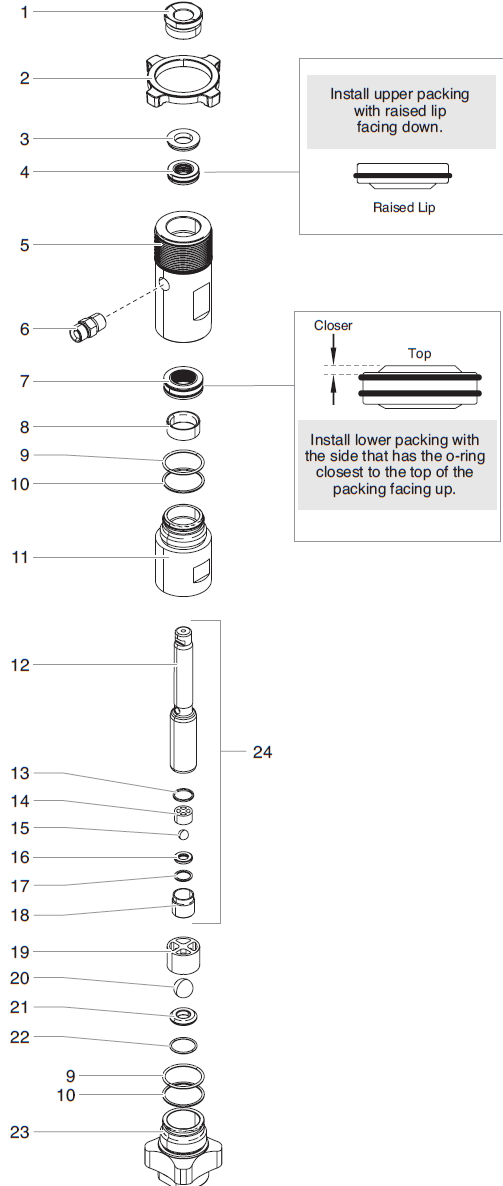

Impact 740/840 Main Assembly

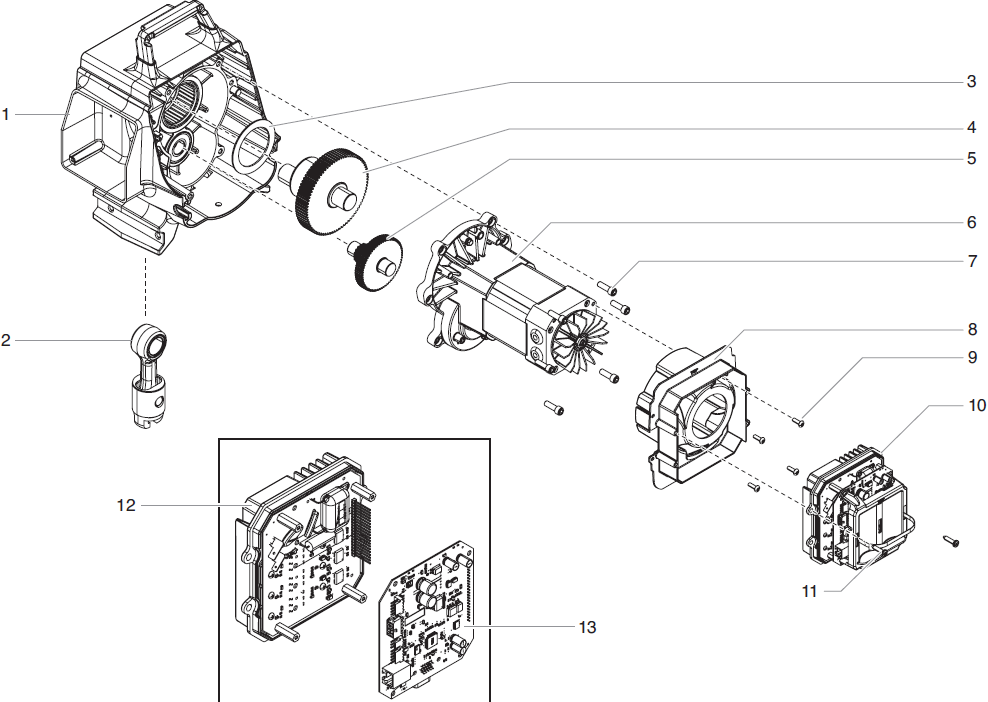

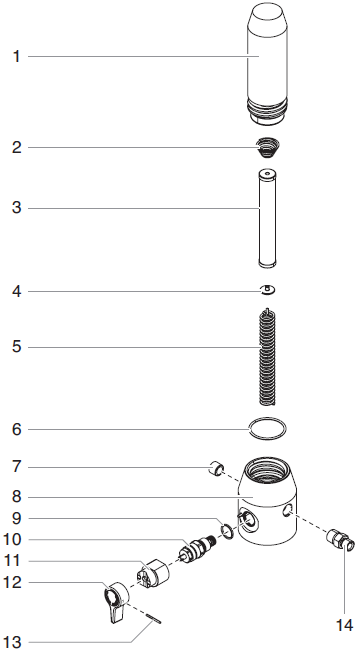

Impact 740/840 Drive Assembly

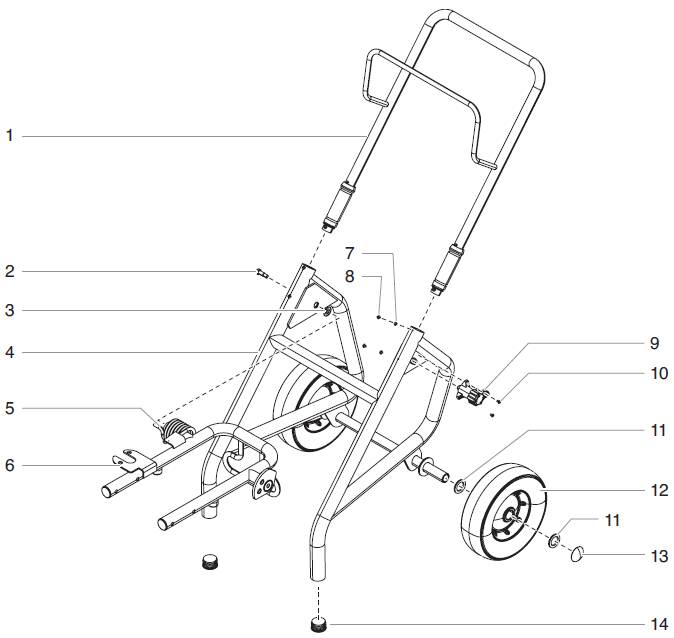

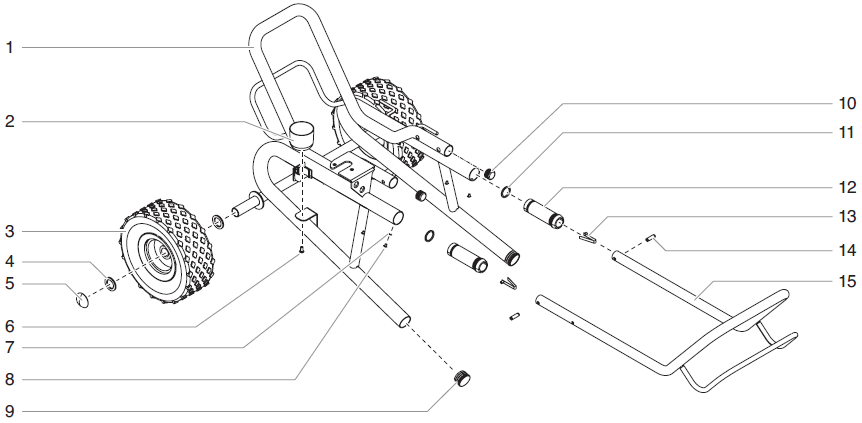

Impact 740/840 Upright Cart Assembly (P/N 805-227)

Impact 740/840 Fluid Section Assembly (P/N 805-1010)

Impact 740/840 Filter Assembly (P/N 805-269)

Impact 740/840 Low Rider Cart (P/N 805-289)

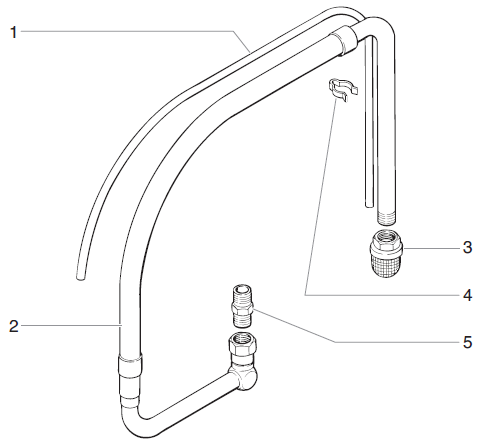

Impact 740/840 Low Rider Siphon Assembly (P/N 805-296)

Impact 740/840 Accessories

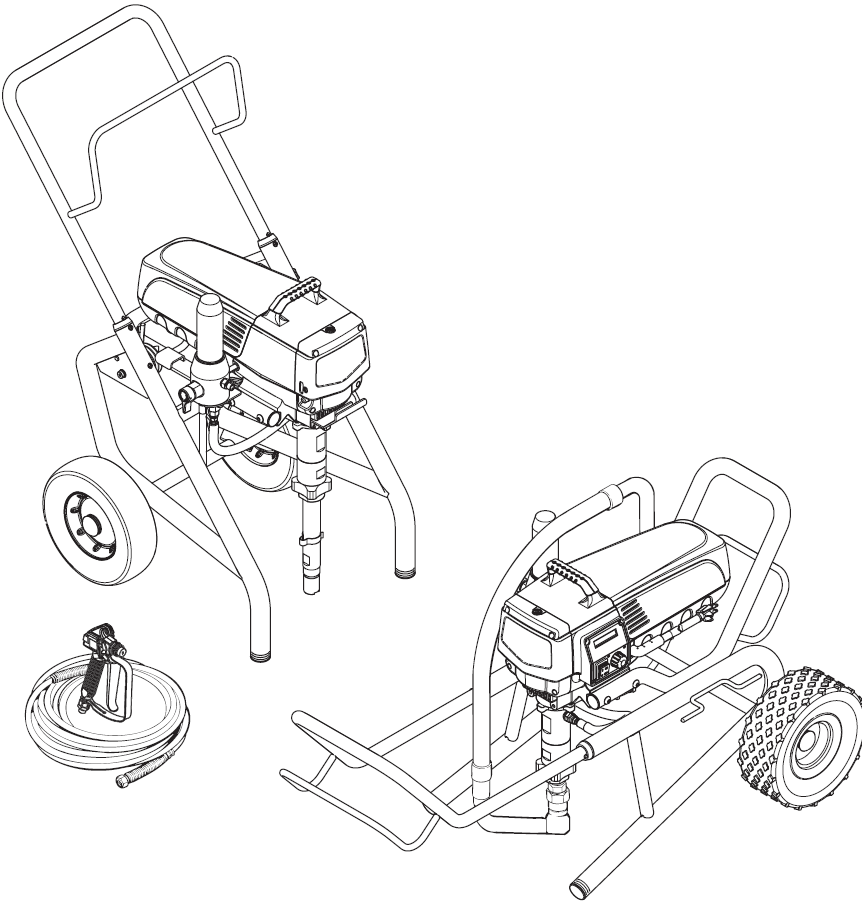

NEW PRODUCTS FOR DECEMBER - IMPACT 740/840 AIRLESS SPRAYER

The Impact 740/840 Airless Sprayer is a high-performance, contractor-grade paint sprayer designed for professionals who need power, durability, and long-lasting consistency on demanding job sites. Built with advanced fluid management technology, it delivers smooth paint flow and superior atomization — even with heavy coatings.

For detailed parts breakdown and accessories, you can view the Impact 740/840 Sprayer Assembly on the official Titan parts page

The Impact 740/840 Airless Sprayer is ideal for:

The Titan Impact 740 Airless Sprayer is built for medium-sized residential and light commercial projects, while the Titan Impact 840 Airless Sprayer delivers higher pressure and flow rate, making it suitable for large-scale commercial and industrial applications. Both models offer durable Impact 740/840 Main Assembly parts and long-lasting performance for consistent spray results.

For optimal operation, inspect and clean your Impact 740/840 fluid section, filters, and hoses every 50–75 gallons of use. Regular maintenance—like lubricating the piston and replacing worn seals ensures your Impact 740 and 840 parts last longer and prevent costly downtime.

Yes! Both sprayers are engineered to apply a variety of coatings, including stains, latex paints, enamels, primers, and acrylics. Using the right Impact 740/840 spray tips and filters ensures smooth application whether you’re working on walls, ceilings, or exterior projects.

If your Impact 740/840 Airless Sprayer experiences pressure loss, check the filters for clogs, inspect the suction set for air leaks, and make sure the Impact 740/840 Fluid Section Assembly is properly cleaned and lubricated. Replacing worn packings or valves often restores normal spray pressure.

To maximize durability, clean your sprayer after every use, flush it with the recommended solvent, and store it in a dry, safe location. Replacing Impact 740/840 accessories parts, such as filters, pistons, and seals, at regular intervals helps ensure consistent, professional-grade performance for years.