When you are working with a sprayer, you have to understand that there are different parts that are connected to it for different purposes. If you do not have an idea about the functioning of these parts, you will never be able to get accuracy in your work, no matter what you do.

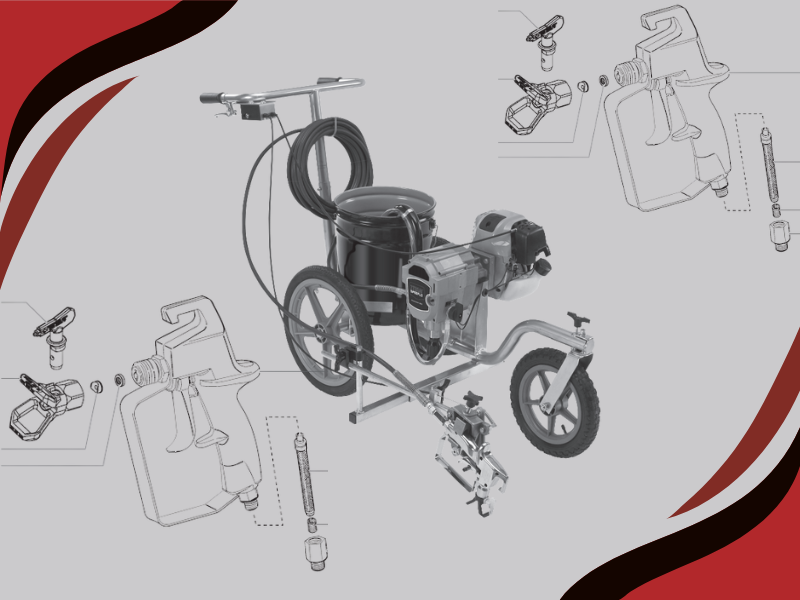

To sort this problem out for you, today we are going to talk about the filter parts of the Speeflo Powrliner 800, so you can be well-informed about the details. Let’s dive right into the filter parts of this specific sprayer so you can start your work right away.

The first part of the filters is the inlet filter, which is extremely important for the function it performs. This is considered the first line of defense because all the larger debris is stuck on this filter and it prevents it from entering the pump. If the inlet filter is not working properly, you will face a lot of problems with clotting and will also get inaccurate results.

The second filter part is the main filter that again is essential for the role it plays. This filter is present in the pump where the fluid section is present. The main filter is more defined and finer as compared to the inlet filter. The main purpose of this filter is to catch smaller debris from entering the pump so it does not interfere with your work. Again, if the main filter is not performing its job, you will struggle a lot at the work.

The last part is the handle filter, and it is known so because it is present in the handle of the spray gun. It is known to be the finest out of all three filters. The purpose of this filter is to make sure that only the clean paint reaches the surface and the paint overall is really smooth and fine. This hugely plays a role when it comes to preventing all sorts of clogs in the spray.

You need to know that the mesh size of the filter matters a lot when it comes to preventing clogs. Not only that, but you also need to check these filters every now and then to see whether they are working fine or not. If you are not careful about the filters, there can be too many problems that you will face while working.

Filters have a big role to play when it comes to spraying because if they are not acting properly, you will never be able to get the finest finish. They prevent the spray from getting clogged and also help in getting rid of debris that can otherwise be present in the sprayers.

That being said, if you’re looking forward to getting these parts for your Speeflo Powrliner 800, then do not think twice and get in touch with us at AllTitanParts. We provide our customers with top-quality parts so they can get the results they desire at the job site.